Learn all about the process of grinding parts in metalworking in this must-see infographic.

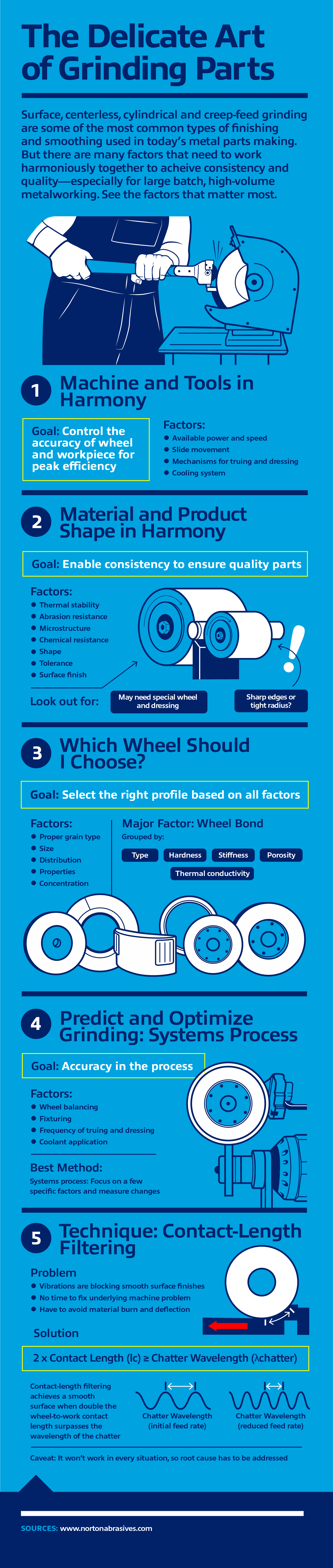

Surface, centerless, cylindrical and creep-feed grinding are some of the most common types of finishing and smoothing used in today’s metal parts making. But there are many factors that need to work together in harmony to achieve consistency and quality—especially for large-batch, high-volume metalworking.

One challenge that sometimes happens in grinding is waviness—which can be problematic. Peter Zelinski, executive editor of Modern Machine Shop, puts it this way in the article “Keep Calm and Continue Grinding,” where a technique called “contact-length filtering” developed by Saint-Gobain Abrasives, owner of the Norton brand of abrasive products, is highlighted:

“In a production-grinding operation, waviness on the part surface is a potential clue that the machine or process has developed a vibration problem. The effect might be seen in inspection, or if there is a lapping or polishing step, the effect might be seen in the increased time spent removing the waves.”

Learn more about this technique, along with the factors for selecting a grinding wheel and other details surrounding grinding, including wheel dressing and coolant systems, in today’s advanced manufacturing environments.

To learn more about grinding, see below the infographic.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *