KYOCERA SGS Precision Tools, Inc., formerly known as the SGS Tool Company and a wholly-owned subsidiary of KYOCERA Corporation, was originally founded in 1951 and is an ISO-certified leader of round solid carbide cutting tool technology for the aerospace, metalworking, and automotive industries. Today, it is best known for its solid carbide high performance end mills and drills. However, it is also well known for its stainless steel medical tools and technically advanced, proprietary PVD coatings. KYOCERA SGS Precision Tools, with manufacturing sites in the United States and United Kingdom, aggressively services its customers through a global network of Sales Representatives, Industrial Distributors, and Agents that sell into more than 60 countries.

In the intricate world of CNC machining, choosing the right tool can sometimes feel like navigating a complex maze. Each decision impacts your journey towards achieving the perfect balance of efficiency, precision, and productivity. One of the critical decisions you’ll encounter is whether to use a multi-flute tool. Let’s explore this maze together, drawing from the wisdom shared by Jason from KYOCERA SGS Precision Tools R&D department, to help you decide when more flutes are the key to unlocking your machining potential.

The Intersection of Feed Rate and Productivity

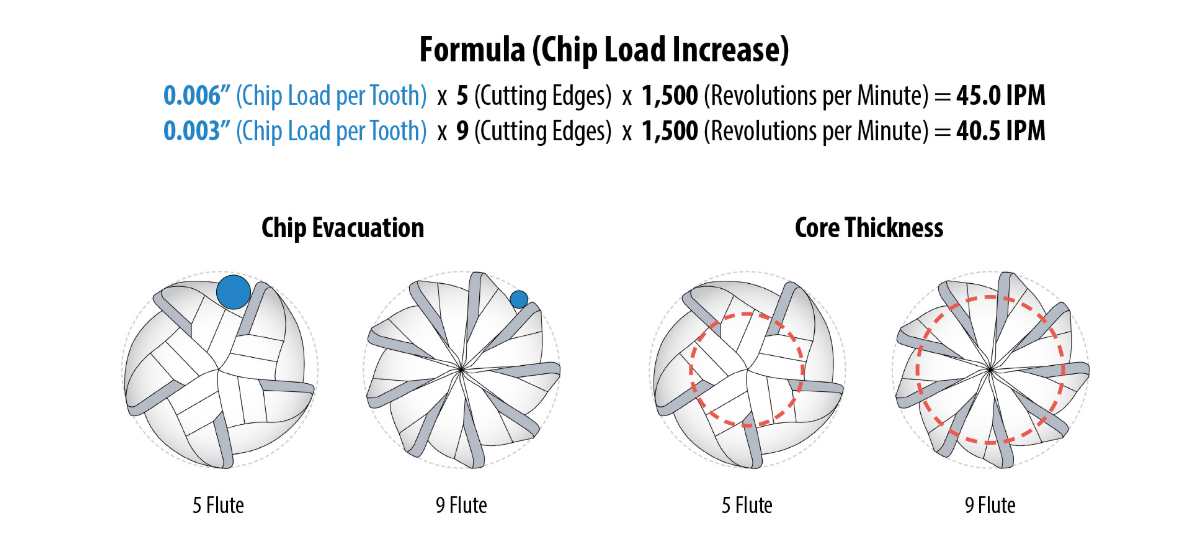

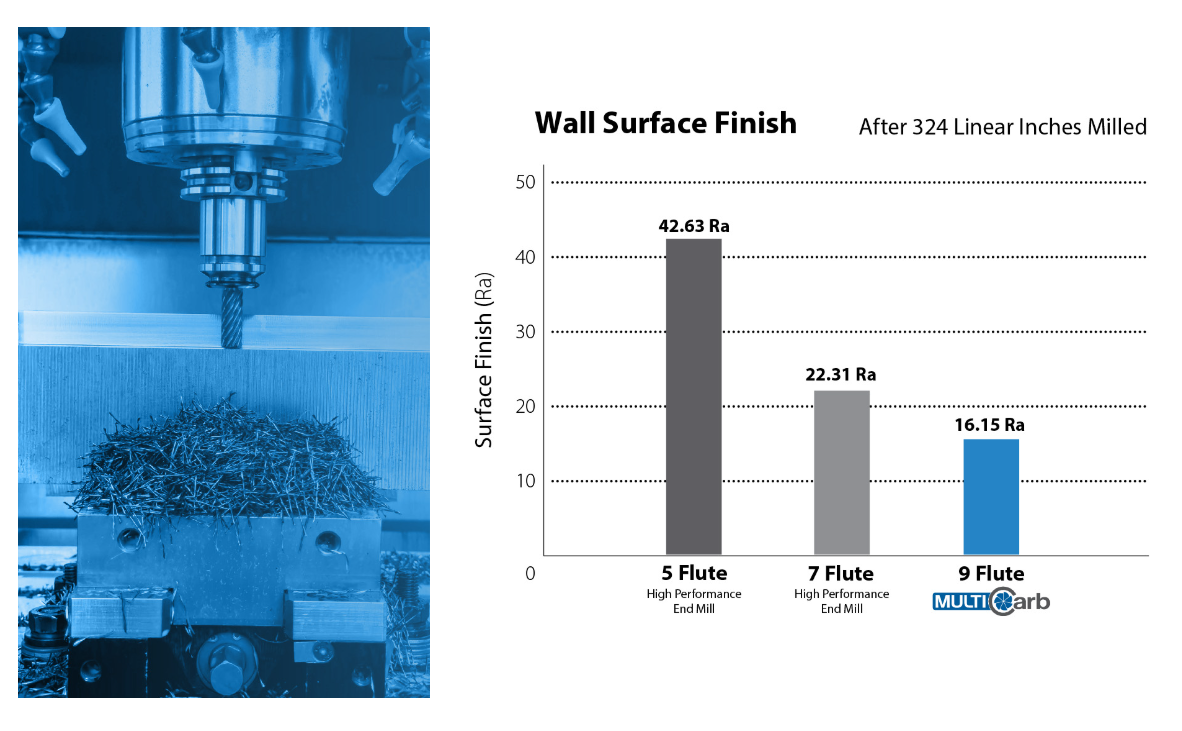

Imagine you’re at the intersection where speed and efficiency meet. Here, multi-flute tools shine brightly. Jason succinctly explains, “The greater number of cutting edges on a cutting tool allows you to achieve a greater feed rate. Feed rates then allow you to gain greater productivity.” This means that when you’re aiming to move through material quickly and boost productivity, multi-flute tools are your allies.

The Twist and Turns of Tool Core and Chip Evacuation

As you navigate further into the maze, you’ll encounter a twist: the relationship between the number of flutes and the tool core. More flutes mean a larger core, which reduces flute depth and limits chip space. This trade-off is crucial. Jason notes, “As you add cutting edges or flutes to a cutting tool, the center of the tool, which is known as the core, gets larger. This gives you less flute depth or less space for creating chips during the machining process.” Understanding this balance is key to choosing the right tool for your specific path.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *