This article was updated on January 14, 2024.

Most machinists would agree that a properly mixed, high-quality cutting fluid smells quite pleasant. But if it isn’t maintained or cleaned, cutting fluid can start to stink.

Give it a couple of weeks of neglect and the Monday morning stench is enough to make even the most olfactory-challenged machinist yearn for the weekend. If the assault on your nose isn’t bad enough, however, rancid coolant is hard on other things too—from your health to tool and machine life, finishes and a host of key metalworking processes and parts.

Here are a few pointers on optimizing coolant maintenance, which can buoy productivity while helping to protect your shop’s most important assets: its workers.

Is CNC’ Coolant Bad for Your Skin?

To be fair, even freshly mixed cutting fluids contain a host of chemical additives such as biocides, emulsifiers, corrosion inhibitors and anti-foaming agents that may cause skin irritation, rashes and dermatitis. When cutting fluid gets dirty or is improperly maintained, however, health risks increase significantly.

When cutting fluid is neglected, the concentration of these chemicals may reach unsafe conditions. Also, an improperly maintained machine tool sump becomes a perfect breeding ground for microbes.

“At low concentrations, bacteria can grow unimpeded in the sump and cause pH of the coolant to drop and cause rust,” says John Treese, director of global training at Master Fluid Solutions. “Low concentration [of fluid] can grow bacteria that can aggravate skin issues including simple cuts and scratches. High concentration adds too much chemical that can do the same.”

Aside from creating noxious odors and degrading coolant, these microorganisms—when combined with tiny skin abrasions—can hasten the chance of infection.

“Microabrasions,” as they are known in the industry, happen when extremely fine chips and swarf reside in dirty coolant, not so much the larger chips we see flying off the workpiece during the cutting process, explains Jim Brumgard, an application engineer in Castrol’s industrial division.

“Of course, big chips can cause cuts, but that type of cut usually requires first aid,” Brumgard says. “The skin abrasions occur when there is coolant splashed onto the skin and then the operator wipes away the dirty coolant … These often microscopic, tiny fines will cause the scratches as the towel or rag is wiping them across the skin.”

Read More: Nanofluids Make Machine Shops More Competitive Through Science

They are usually perceived as irritated skin, but what has actually happened is that tiny cuts have allowed the coolant to worsen irritation due to broken skin. Bottom line: The dirty coolant has become abrasive to the skin and leaves it more susceptible to irritation, Brumgard asserts.

That’s why coolant should be treated with respect. Wash hands regularly with a mild, nonabrasive soap. Use a moisturizer to create a protective skin barrier that slows the absorption of chemical additives.

Wear thin nitrile gloves if practical (though never wear heavy gloves around machinery). Keep clothing clean and dry. And avoid using solvents to clean parts, as these eliminate the natural oils on our skin, leaving it unprotected.

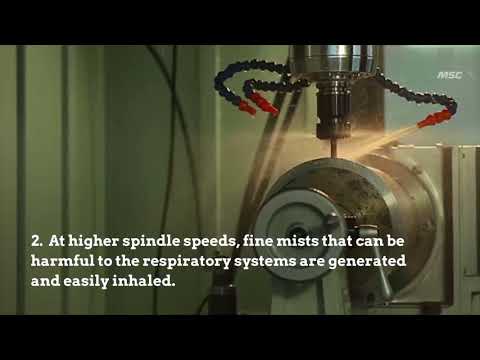

Fine Mists Can Harm the Respiratory System

Though less noticeable, the delicate tissue lining our lungs is even more susceptible to irritation than our skin. This can be especially problematic at higher spindle speeds, where fine mists are generated and easily inhaled.

Unfortunately, the negative health effects connected to mist might not be noticed until years later. If your lathe or machining center isn’t equipped with a properly sized, high-performing air purifier and mist collector, wearing a face mask would be an excellent idea, even if you do perform routine cutting fluid maintenance. Clean coolant might smell darned nice, but that doesn’t mean you should inhale it.

Be Clean w****ith Machining Coolants—and Your Machine

As a rule, water-soluble or “miscible” cutting fluids are fairly alkaline, with a pH of around 8.6 or higher. This helps to prevent corrosion of metal surfaces, keeps microorganisms in check and is a bit easier on human skin. It does, however, tend to eat paint and even rubber seals, especially on older machines not designed with modern cutting fluids in mind.

To minimize this, it’s a good idea to wipe equipment down before going home at the end of each shift. Regularly inspect seals and wipers for wear and replace as needed. Install a skimmer on each machine to eliminate tramp oil, bacteria’s favorite food.

“Tramp oil will slowly dissolve into the coolant, causing it to get thicker and stickier with time,” Treese explains. “Bacteria can feed easily on this emulsified tramp oil and then can attack the coolants’ oils as well. It is also harder to maintain the proper concentration when the sump is full of chips."

“Machine life suffers from dirty coolant: That’s a true statement. Fluid will attach itself to the workpieces, but also to the chips and the dirt, and so you have to monitor coolant for all these things.”

Jim Brumgard,

Application Engineer,

Castrol Industrial

The chips and sludge are displacing coolant, so the volume is ever changing. Keeping the sump clean makes concentration control easier. Monitor pH with a meter (preferred) or test strips weekly—if pH is falling, there’s a good chance that something nasty is growing down there. Time to give the machine a thorough cleaning and install some fresh coolant.

Dirty Coolant Curbs Machine Tool Life

Cutting fluids provide lubricity and remove heat from the work zone. As coolant breaks down, the sulfur, chlorine and other extreme-pressure compounds contained within become ineffective. This leads to poor tool and machine life as well as problems with accuracy and part quality.

“Machine tool life suffers when concentrations drop below the coolant manufacturer’s minimum concentration suggestions and can cause rust on the machine tool,” Treese says. “There’s just not enough chemical to protect the machine tool.”

“Machine life suffers from dirty coolant: That’s a true statement,” Brumgard says.

“Fluid will attach itself to the workpieces, but also to the chips and the dirt, and so you have to monitor coolant for all these things.”

But there’s more damage that can occur to the machine itself—and to filters and pumps.

“The dirt in your coolant will be abrasive, it will scratch paint, and it will scratch the glazing on a machine’s windows inside a newer machine with a cabinet around the work zone,” Brumgard says. “The other things it can hurt and wear out are pumps, especially high-pressure pumps, even when they have extra filtration to protect the pump from wear.”

So that means there’s a cost of changing filters and making sure the filter is not bypassed or ignored, Brumgard explains. Some might think to remove the filter, but then you start really wearing out costly components.

And with through-the-tool coolant delivery holders, you have to pay attention to the rotary coupling’s wear, to avoid leakage, Brumgard points out.

It’s better to focus on maintaining a clean coolant operation. Here are some ways: Aside from skimming and filtration, cutting fluid concentration should be checked with a refractometer at least weekly, refreshing tired coolant as necessary with properly mixed makeup fluid.

One way to accomplish this is with an automatic proportioning unit that sits on the drum, allowing the operator to dial in whatever percentage of fluid is needed to bring the sump back to the correct concentration.

If you don’t have such a unit, remember the acronym OIL, short for “oil in last,” when mixing any cutting fluid. Your cutting tools will thank you.

Another way to protect tools is by investing in high-quality fluids such as those in Master Fluid Solutions’ signature TRIM HyperSol 888NXT line. HyperSol is designed not only to optimize machine performance but also to prolong tool life and reduce production time.

The biobased formula of HyperSol 888NXT keeps it smelling better longer, unlike older metalworking fluids.

Fluid Maintenance Matters to the Bottom Line

Buying cutting fluid—and disposing of it after use—are necessary expenses. Though these costs don’t compare to the expense of an idle CNC machine tool, it’s a good idea to maximize coolant life whenever possible.

Shops with a few dozen machine tools might consider a centralized cutting fluid system. In lieu of this, a coolant recycling center is probably the best bet. Use a shop vacuum or sump cleaner to bring old cutting fluid back to the reservoir for processing.

Here again, maintenance is key. The mantra is: Skim constantly, clean regularly and check religiously. Watch fluid concentrations, using no more concentrate than is necessary but without skimping—as a rule, 10 percent is a good starting point for general-purpose work, although difficult materials such as titanium and superalloys may call for a slightly higher percentage, while aluminum generally cuts best with a leaner mix.

But be careful, warns Treese: “If a manufacturer of coolant recommends a 10 percent concentration in the sump, running at 20 percent actually doubles the amount of chemical in the sump—it does not add 10 percent more chemical as some think.”