Manufacturing facilities wanting to find cost savings or improve throughput may overlook the cutting and grinding process — mistakenly thinking those operations are too small to make a significant impact on the bottom line.

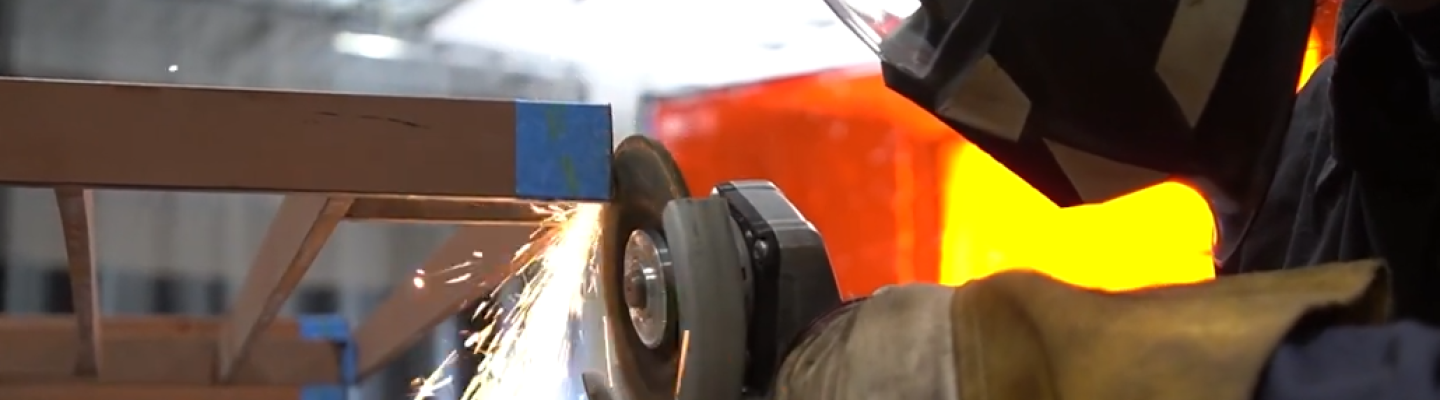

Much of the time, abrasive products are simply viewed as consumables and a small piece of the overall puzzle. However, the choice of abrasive and how the product is used can have a substantial impact on production upstream and downstream because the abrasive affects operator efficiency, labor costs and overall quality of the finished product, among other factors.

Learn more about how studying data from the manufacturing process can help your operation choose the right abrasive product and uncover cost and labor savings.

IMPACT OF ABRASIVE PRODUCTS

Some manufacturers choose abrasive products based solely on initial product cost. However, using a cheaper wheel or the wrong wheel for the job can significantly affect throughput, long-term costs and productivity. Because labor is typically the highest expense in any operation, any change that reduces downtime and improves productivity for operators has a positive ripple effect through the entire production operation.

Whether the work involves a grinding wheel, flap disc or cutting wheel, there are several ways that abrasive products can affect throughput, costs, downtime and productivity in a manufacturing operation. Consider these common challenges that add time and costs:

-

Unnecessary downtime for wheel changeover: Choosing the wrong abrasive for the application can result in a product that doesn’t perform as needed. As a result, the operator may use the wheel incorrectly, the wheel may fail prematurely or there may be more frequent changeover. This adds unnecessary downtime, which can create bottlenecks and labor inefficiency in the operation both upstream and downstream of the cutting and grinding process. Minimizing wheel changeover reduces downtime and improves efficiency, allowing companies to reallocate an operator’s time elsewhere in the facility to help boost throughput or perhaps add another workstation.

-

Reduced product life: Using the incorrect abrasive for the job or the material can also reduce expected wheel life. Not only does this force operators to change the wheel more frequently, but it also drives up costs because more abrasive products are being used. Choosing the correct abrasive helps improve efficiency and allows operators to use the wheel to its full life, resulting in fewer abrasives being used and ultimately labor and cost savings.

-

Too much rework: For many manufacturing operations, their products must be inspected or tested to meet certain specifications for customers. If the finished product doesn’t meet the standards, it requires rework and/or the part could possibly be scrapped entirely. Rework adds material expenses and labor time, driving up the costs. Choosing the appropriate abrasive for cutting and grinding can help operations minimize rework and ensure quality results for the material and application needs.

A COMPREHENSIVE REVIEW

If your operation could shave six minutes off every hour in the abrasives process, what would that equal in savings for the entire year? There is a way to find out. Measuring the total operating costs associated with your abrasive consumables can identify efficiency gains and time savings to help your operation optimize labor and save money. But it’s important to look at the entire operation and all the factors involved with the abrasives process to get the full picture. Even a small change in one part of the operation can have significant ripple effects throughout the entire production line.

For example, poor part fit-up in the material prep process negatively impacts operations downstream. Operators must spend additional time to correct the poor fit-up, and they must use extra filler metal to fill that gap. If a standard cutting wheel is used to prepare the material for production, it can potentially leave burrs and an uneven cut. A switch to an ultra thin cutting wheel delivers faster, smoother and cleaner cuts — which means the operator spends less time on burr removal and potentially uses less filler material to complete the weld.

Watch now: Weiler Consumable Productivity: Save Time & Improve Metal Fabrication Operating Costs

Partnering with an abrasives manufacturer for this type of comprehensive review helps ensure that you’re looking broadly at all aspects of the process rather than focusing on simply swapping out your current abrasive for something else. It’s important to look beyond the specific wheel being used because perhaps the problem stems from something else.

It’s important to consider all factors, from the angle of the tool to the work environment where the product is being used. The analysis should also look at any challenges the operation faces, their goals and how they measure success. Considering all of this information helps ensure a comprehensive improvement plan.

REAL-WORLD EXAMPLES

One such offering is the Weiler Consumable Productivity (WCP) program, which helps facilities find cost and time savings in their fabrication operations when they may not have the resources or process to quantify results themselves. The process effectively and efficiently measures real-world data and can take minimal effort to deploy in a facility because abrasives experts implement it.

The program can help companies identify improvements by evaluating the overall operation and how abrasives are used in a facility. The approach includes an on-site assessment by abrasive experts so they can learn firsthand about the production process and collect data on how the abrasives are used. First, a baseline is established by capturing data on the current process. That is followed by testing of the current process and abrasives. The experts then calculate the estimated annual savings that a product change could provide based on labor, time and consumable consumption. They use data to build a focused plan to eliminate inefficiencies in production by using the best abrasives for the application — and potentially improve productivity and throughput.

In one pressure vessel application, the WCP evaluation process helped find a better abrasives solution that would hold up to the demanding work and deliver longer life — providing an expected annual abrasives savings of more than $62,000 to the customer. In another shipbuilding case study, the customer needed to find an abrasive product that worked on steel to meet government specifications. Throughout testing, the WCP process was leveraged to accurately measure cut rate, wheel life and labor costs. This provided the company with hard data to select the wheel that offered the best productivity and total cost, delivering an annual savings of $20,000 over the other wheels tested.

USING DATA TO OPTIMIZE THE ABRASIVE OPERATION

Whether the challenge to be addressed is a shortage of labor, a high rework rate or escalating consumable costs, any manufacturer or fabrication shop that is looking to make improvements is a good candidate for an evaluation process. Using data from all aspects of the abrasives operation provides a full picture to help uncover solutions that can deliver significant time and cost savings.

Previously Featured on Weiler Abrasives' blog.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *