Fear of Fusion: Does 3D Printing Replace CNC?

This article takes a look at the strengths and weaknesses of both CNC Subtractive Manufacturing (CSM) and Additive Manufacturing (AM).

This article takes a look at the strengths and weaknesses of both CNC Subtractive Manufacturing (CSM) and Additive Manufacturing (AM).

Manufacturing in the modern age is overshadowed by an ongoing debate between two distinct but interwoven forces – CNC Subtractive Manufacturing (CSM) and Additive Manufacturing (AM). This article delves into an analysis of these two approaches, highlighting their respective strengths, and weaknesses, and exploring the burgeoning field of Additive-Subtractive Hybrid Manufacturing (ASHM). Additionally, we will discuss the pivotal role of carbide tooling and its continued relevance in this era.

Before we delve into the intricacies of CNC Subtractive Manufacturing (CSM) and Additive Manufacturing (AM), it’s helpful to understand the “buy-to-fly” ratio. This ratio signifies the mass of the initial raw material billet in comparison to the final finished part mass. In CSM, the “buy-to-fly” ratio is often high, indicating that a significant portion of the initial material is removed during machining. Not only does this result in substantial material waste, but it escalates costs and environmental concerns. The “buy-to-fly” ratio is a relevant concern in industries like aerospace where its complex parts start as massive billets and much of the material is removed to reach the desired specifications [1].

CSM, a tried-and-true method, boasts several strengths:

Precision and Accuracy: CSM is celebrated for its exceptional precision and accuracy, which is vital for industries where even the slightest deviations are intolerable like automotive, aerospace, energy generation, medical, firearms, and mold and die.

Material Versatility: CSM is highly adaptable and can process an extensive range of materials, including metals, plastics, ceramics, and composites, catering to the diverse requirements of various industries.

Superior Surface Finish: It can achieve impeccable surface finishes, a critical feature in applications where aesthetics and performance are paramount.

Speed: Once the setup is complete, CSM can produce parts at a rapid pace, making it ideal for industries with high production demands. The machining speed can further be increased with high-performance carbide tooling like SGS’s Z-Carb HPR and the H-Carb end mills which create premier finishes at high speed.

Nonetheless, subtractive manufacturing has its limitations:

Material Waste and Buy-to-Fly Ratio: A significant shortcoming of CSM is the considerable material waste it generates, particularly when crafting intricate or complex parts. The high “buy-to-fly” ratio leads to increased costs and environmental implications.

Limited Geometric Complexity: While CSM excels in managing intricate geometries, it falls short compared to AM in crafting highly complex, organic shapes, limiting innovation in some design applications. The choice of specialized tooling can alleviate this limitation. Options include ball nose end mills or SGS’s advanced tapered circle segment barrel end mills like the Multi-Carb and APF-B series. Collaborating with SGS to create a custom end mill tailored to the specific requirements of complex geometric components is another effective strategy.

Additive Manufacturing (AM), often referred to as 3D printing, has witnessed a surge in popularity for various reasons:

Complex Geometries: AM excels in creating complex, organic, and intricate shapes, making it the top choice for applications where traditional methods fall short.

Material Efficiency: A standout feature of AM is its material efficiency. It builds parts layer by layer, reducing waste in the production process.

Customization: AM easily accommodates customization, allowing each part in a batch to be different, serving the diverse needs of industries such as healthcare and aerospace.

Tooling-Free: Unlike CSM, AM is tooling-free. This means there’s no need for molds or tool changes for different parts, resulting in reduced setup times.

Additive Manufacturing, in general, offers a range of advantages:

Speed: AM is slower than CSM, particularly when producing larger parts. This limits its application in high-volume production environments [1].

Material Limitations: While AM has expanded its material options, it still lags behind traditional manufacturing in terms of available materials, especially for industries requiring high-performance materials, such as aerospace.

Surface Finish: Achieving the same level of surface finish as subtractive manufacturing can be challenging, particularly for certain materials and printing methods. This makes AM less suitable for applications with strict surface requirements in industries including aerospace, firearms, and medical [2].

Energy Consumption: AM consumes more energy compared to CSM while producing fewer finished goods [1].

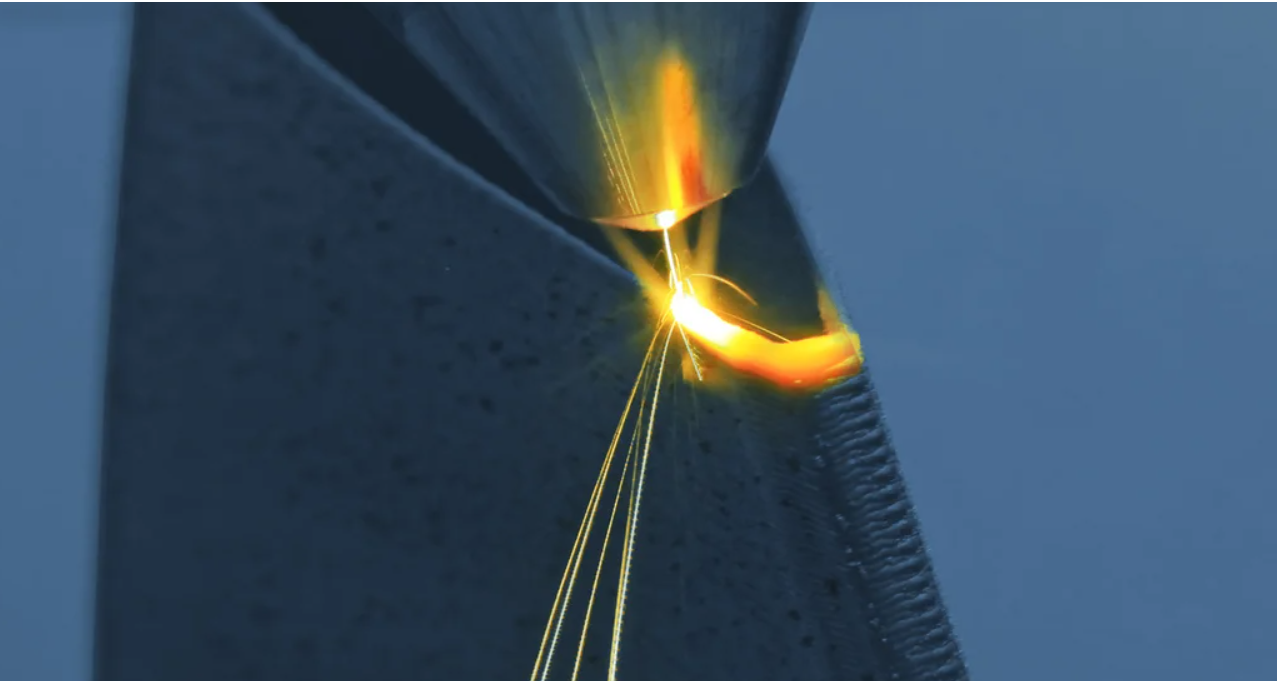

Additive-Subtractive Hybrid Manufacturing (ASHM) represents the amalgamation of the strengths of both AM and CSM within a single workstation. The combination of AM and CSM within a single workstation allows the production of complex parts with internal components requiring the finish quality of CSM. Traditionally, CSM would be incapable of reaching these internal components. ASHM offers many advantages including the following [1,2]:

Material Efficiency and Reduction of Buy-to-Fly Ratio: ASHM significantly curbs material waste by employing AM for near-net shaping. This makes it a more sustainable choice for industries where lightweight parts are paramount. The high “buy-to-fly” ratio often associated with CSM is mitigated by the AM component, conserving materials, and reducing costs [1].

Complex Part Consolidation: ASHM allows the consolidation of multiple parts into one with high accuracy, a feat that can be challenging with CSM. This minimizes assembly requirements and improves overall efficiency [1].

Intricate Geometries: ASHM’s capacity to rapidly craft complex parts with high surface quality, which are inaccessible to CSM, opens new possibilities for innovative designs. Utilizing AM’s layer-building capabilities with CSM providing the finish and precision, new manufacturing possibilities emerge, allowing for the production of intricately designed, high-performance components [1].

Recycling: In the future, ASHM offers the possibility of recycling waste from the manufacturing process and remanufacturing it within the same workstation [2].

Operating an Additive-Subtractive Hybrid Manufacturing (ASHM) system is a complex endeavor, and energy consumption is one of its foremost challenges. While ASHM, like Additive Manufacturing (AM), excels in material efficiency, it’s crucial to note that ASHM’s energy demands surpass even those of AM. This heightened energy consumption within ASHM can be attributed to the amalgamation of multiple energy-intensive devices, including laser machines, chillers, powder feeders, and hybrid machine tools, all operating concurrently and collectively contributing to substantial energy consumption. Nonetheless, ASHM remains a promising technology, especially if the energy problem is effectively addressed [1].

In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for intricate designs, yet it faces limitations in industries that demand speed of manufacture, precision, material variety, and impeccable surface finish.

In this dynamic manufacturing landscape, Additive-Subtractive Hybrid Manufacturing (ASHM) emerges as a promising synthesis of these strengths. While AM continues to make waves, traditional Subtractive Manufacturing and the enduring relevance of carbide tooling remain indispensable.

To excel in your machining endeavors, explore SGS’s extensive range of solid carbide tooling, featuring tools varying from general-purpose to meticulously engineered high-performance end mills with specialized coatings. Talk to your regional SGS Sales Engineer today and find a solution that will drive your production forward.

Previously Featured on KYOCERA SGS Precision Tools' blog.

KYOCERA Precision Tools is a world-class manufacturer of indexable tooling solutions. At KYOCERA, we’re passionate about revolutionary cutting tool technology. We design and develop advanced indexable cutting tools that not only meet but exceed quality expectations, all while delivering the cost-efficiency that today’s metalworking professionals need to stay competitive in a variety of industries including, aerospace, automotive, medical, small parts, and mold & die