There are several types of metal 3D printing technologies ranging from accessible and affordable, to industrial and ultra-expensive. Here are the four main groups to consider.

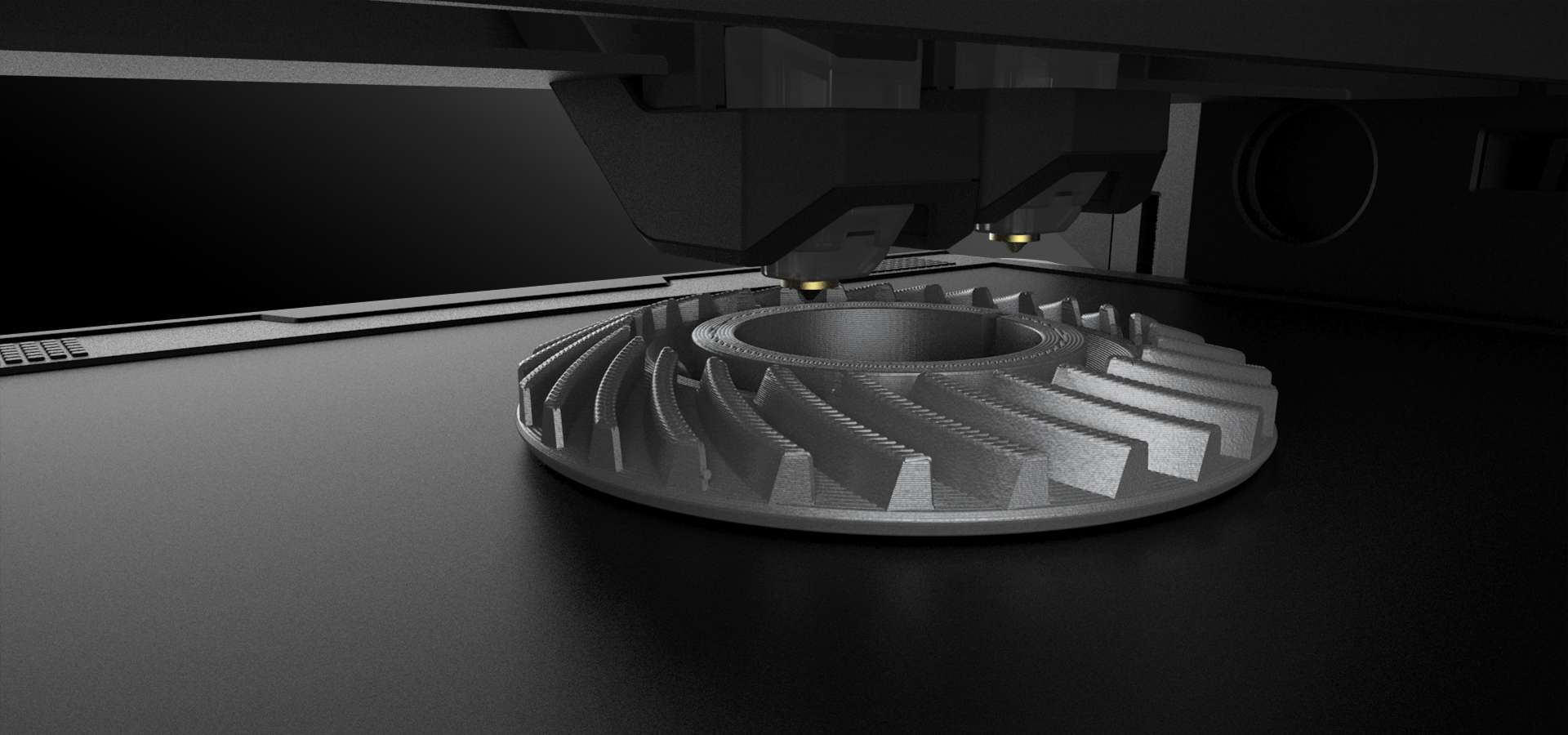

MATERIAL EXTRUSION – FDM

Material Extrusion metal 3D printers come in multiple varieties. FDM is one popular technology and it works by extruding a material that is around 80% metal powder and 20% polymer binder material by weight. Once printing is complete, the print requires debinding and sintering to achieve the desired solid metal part. Material Extrusion is by far the most affordable metal 3D printing technology, at about 10% the cost of the other three categories, making it the most accessible of all types of metal 3D printing when it comes to individual users, small businesses, or at scale within larger businesses.

Hardware Cost $5K - $110K

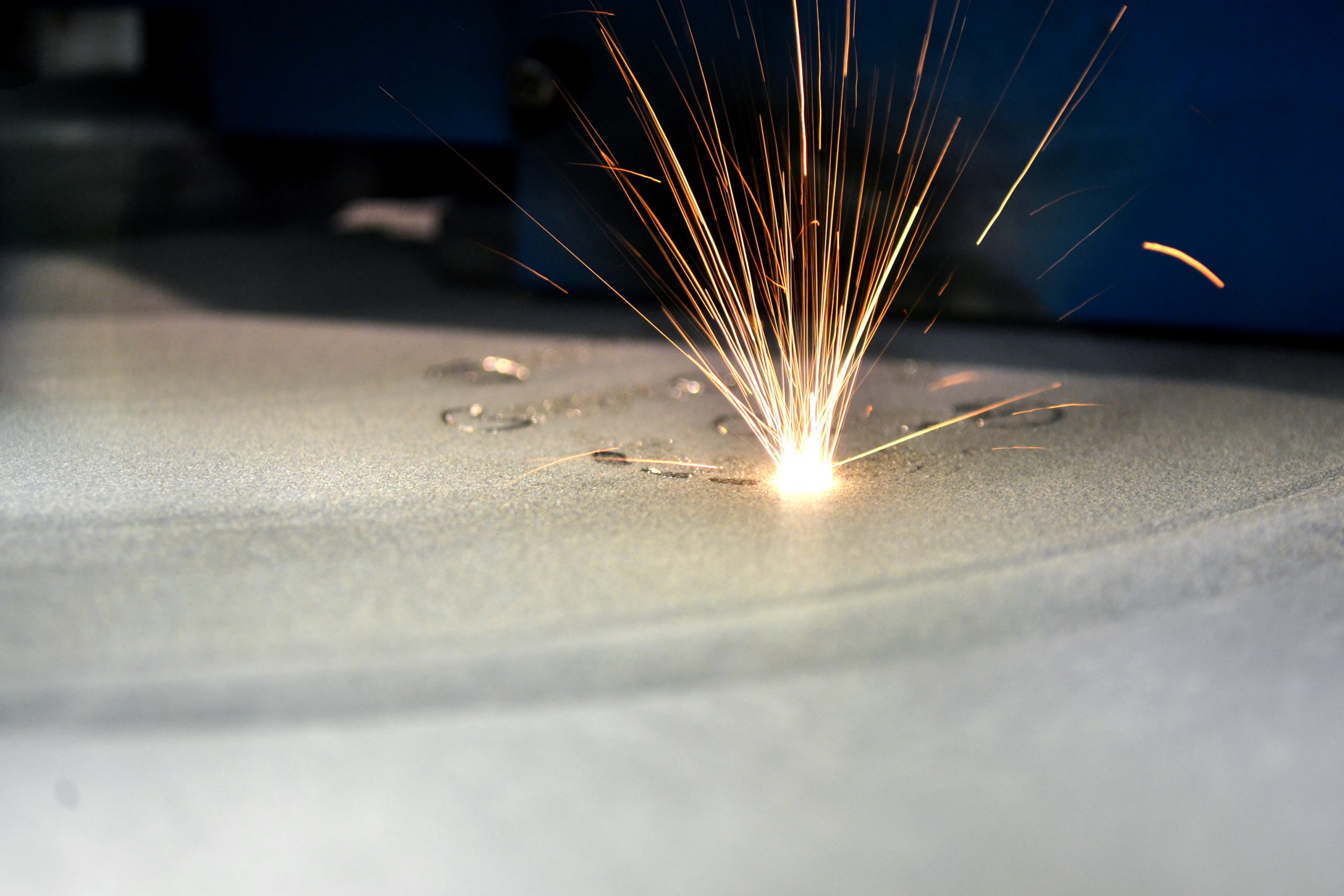

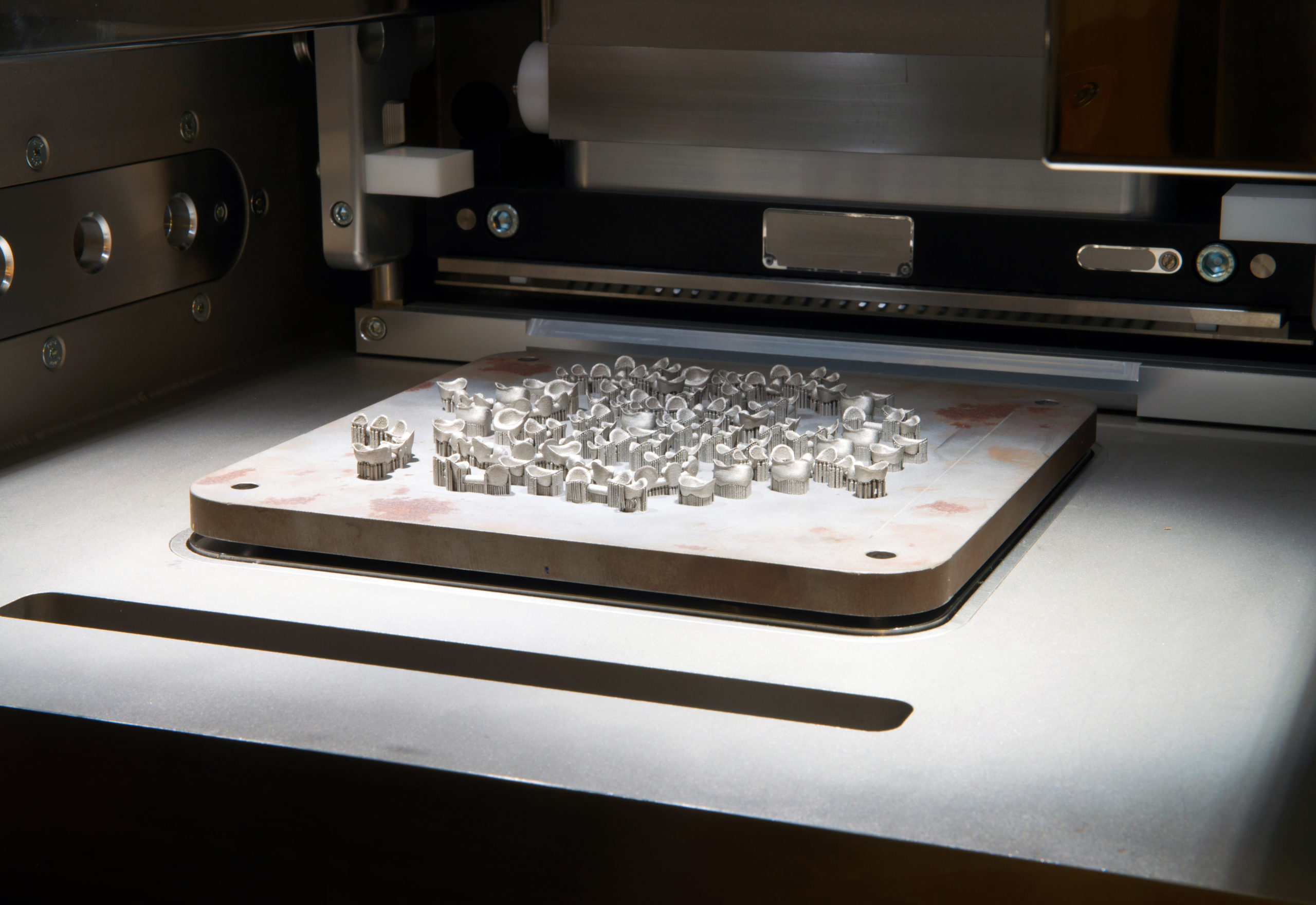

POWDER BED FUSION

Powder Bed Fusion is one of the types of metal 3D printing that actually contains multiple technologies, including Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Direct Metal Laser Melting (DMLM), Selective Laser Melting (SLM) and Electron Beam Melting (EBM). All these technologies use metal materials in a powdered form. A powerful beam of photons (laser) or electrons (EBM) is flashed onto the individual powder particles to sinter or melt them, ultimately to form a strong bond with the adjacent particle. By flashing the beam on the required particles according to the geometry, the powder is melted together and the object is formed.

Hardware Cost $150,000 - $1M

.jpg?itok=86DVhsG4)

Talk to Us!

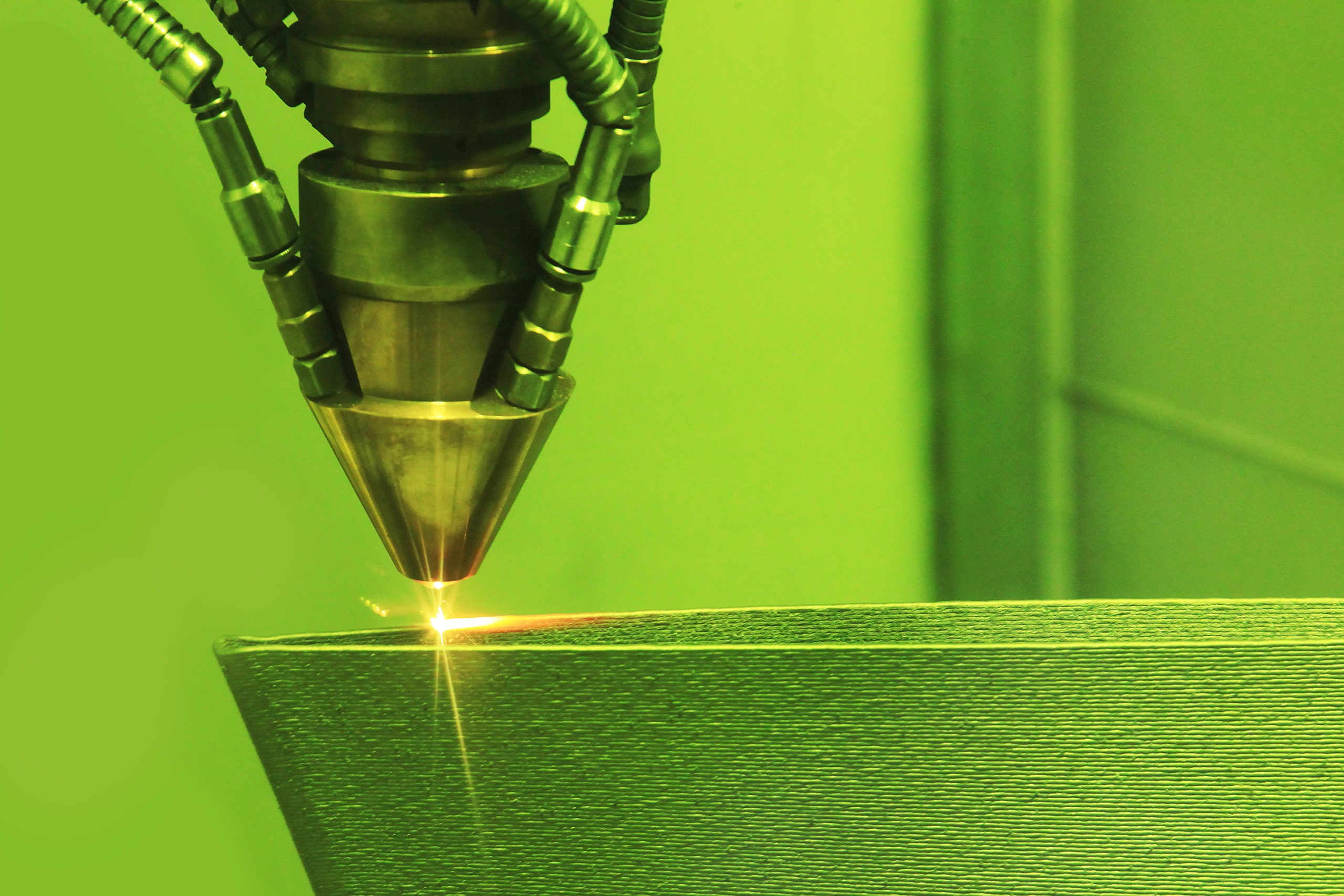

From powder bed fusion to directed energy deposition, the diverse range of metal 3D printing technologies is revolutionizing manufacturing. Explore the future of additive manufacturing and unleash limitless possibilities.

54Leave a reply

Your email address will not be published. Required fields are marked *