IIoT devices feature powerful sensors that can collect real-time, second-by-second production data on the shop floor for use in developing valuable insights for improving the efficiency of operations.

Manufacturers are already using IIoT technology to help them massively reduce machine downtime and out-of-spec end products. They can also be used to make automated machine tool adjustments when they are trending toward out of tolerance, confirming whether the piece should be pulled for production and sent for rework or to the scrap bin.

Looking to the future, manufacturing promises to be a much more cloud-based reality so that facilities with multiple locations will be better able to leverage networked data storage, management and off-site analysis.

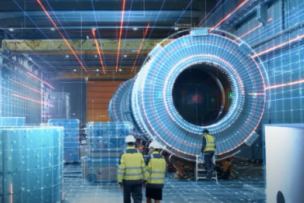

Because it enables optimizations at every step of the production process, quality measurement is critical for operations in the smart factory. Now, all equipment in the plant is connected to the internet, collecting a diverse range of data that can be put to use on the production floor. As a result, new smart measuring systems can now provide real-time information to help factories achieve a new vision for quality assurance and transform their operations into agile, dynamic environments.

By building on the power of real-time data visualization, innovations in smart quality measurement are enabling new insights that can benefit the manufacturing floor—and the bottom line.

Smart Measuring Systems and the Power of Data Visualization

In the past, measurement equipment would fail with no warning or frequent error codes would lead to service calls and subsequent costly downtime. Understanding the strategic importance of the vast amounts of data available at all stages of the manufacturing lifecycle, manufacturers are now reaping the benefits of capturing that real-time data and converting it into actionable insights.

Real-time data visualization provides critical tools— such as role-based views, real-time alerts and notifications, and remote tracking and monitoring. Now, manufacturers are using these tools to help them keep equipment operating to its full potential and to schedule timely maintenance and minimize production disruption.

Intelligent measurement technology is one of the most important Industry 4.0 innovations for the smart factory. Today’s smart measurement systems (SMS) use industrial sensors and state-of-the-art network technology to conduct the measurement of components previously completed by conventional machines that could not learn and adapt to the situation or environment. SMS technology leverages the power of data visualization to enable new capabilities. Now, smart factory operators can remotely monitor the operational status of the machines and key parts being measured, use inspection data to reduce defective parts and enable preventive maintenance by monitoring the condition of the measurement machine.

By leveraging the vast amounts of data generated by IIoT, AI and other technologies, smart measuring systems can provide many of the key capabilities smart factories need. With the ability to monitor the status and current condition of measuring machines, and leverage the power of that data collection/analysis, smart factories can improve process efficiencies and ensure product quality.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *