Sandvik Additive Manufacturing, with its base in Sandviken, Sweden, serves the whole Sandvik Group and has the ability to provide a complete offering, from idea to finished product, at a time when many companies are starting to realize the benefits of additive manufacturing (AM).

Sandvik Additive Manufacturing, the Sandvik Group’s latest product area, is constantly developing and growing with more resources, capabilities, employees and customer requests, as the competitive landscape within additive manufacturing rapidly evolves.

“The metal additive manufacturing market is still very young and small, but it's an attractive high-growth market. In 2015, metal additive manufacturing was just beginning to move beyond an R&D and prototyping tool into a manufacturing tool. In 2017, the move towards becoming a full-fledged production technology accelerated, for example, within aerospace, medical and tooling," says Kristian Egeberg, President of Product Area Additive Manufacturing at Sandvik Machining Solutions, the business area to which Sandvik Coromant belongs.

Mikael Schuisky, Operation Manager at Sandvik Additive Manufacturing, says Sandvik Group has a unique position.

“The Sandvik Group has the competence to provide a complete offering, from an idea to a finished product,” he says, also referring to the business area of Sandvik Materials Technology, which is a world-leading supplier of metal powder used in additive manufacturing. “You can’t find many other companies with competence in everything from in-house powder production and development, AM design, AM process selection and leading expertise in post-processing technologies, such as machining or sintering.”

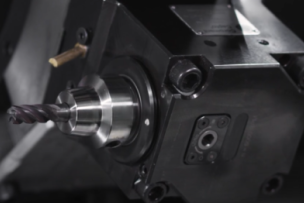

Sandvik Group’s capability within both additive manufacturing and traditional, subtracting manufacturing through CNC machining, is also unique, says Egeberg, referring to Sandvik Materials Technology's neighbor in Sandviken, Sandvik Coromant.

“Additive manufacturing is fantastic for certain applications, but for others, subtractive manufacturing will remain more cost-efficient,” he says. “We have the capability in-house to offer products and advice related to both areas.”

Schuisky says the initial discussion with customers around manufacturing method is central.

“Ask a metal cutting company and then a printing company, and you will get completely different answers to the most suitable manufacturing method for your component,” he says. “As we have competence in both methods, our customers will get unbiased recommendations.”

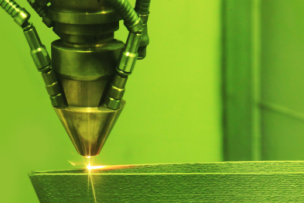

Generally, additive manufacturing is the better choice when producing components with complex designs.

“Additive manufacturing totally redefines our approach to design and to what's possible to produce in one piece, but it takes an open mind and quite a bit of designing skills,” Schuisky says.

To clarify, he shows a component made from traditional metal cutting, and its equivalent, additively manufactured. They look like two completely different components.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *