Being one of the most common jobs in modern machine shops doesn’t keep holemaking from being frustrating—thanks to issues like drill wandering and poor chip evacuation—but it does create an opportunity.

Because machinists drill so often, it’s an operation where tool upgrades can deliver maximum benefits to shops’ productivity, efficiency and bottom lines.

In the past two years, MSC suppliers have introduced state-of-the-art drills including Guhring’s InoxPro, OSG’s ADO-TRS and Kennametal’s Drill Fix Pro that are designed to smooth some of the application’s thornier challenges.

Here’s a look at what they have to offer:

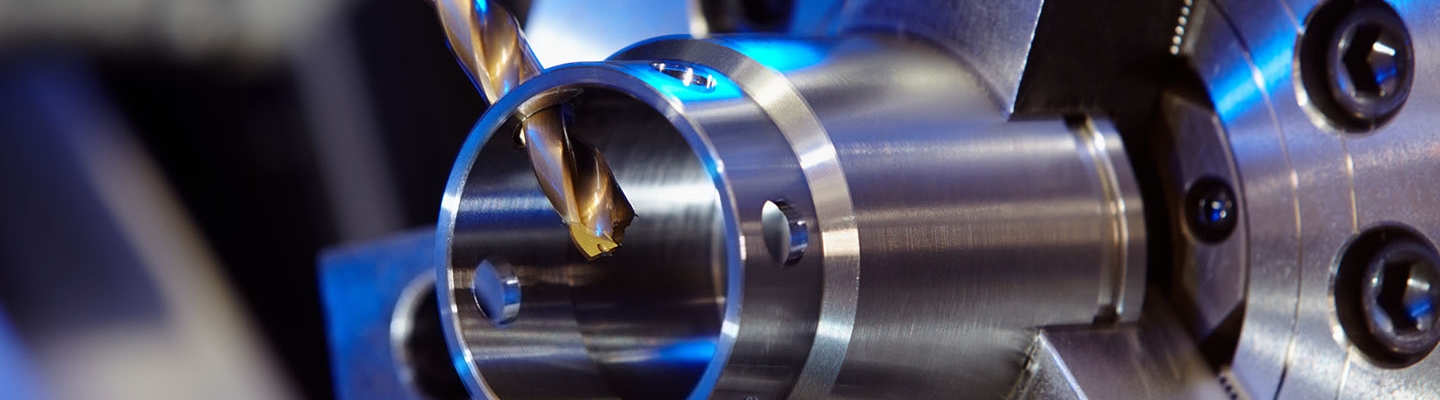

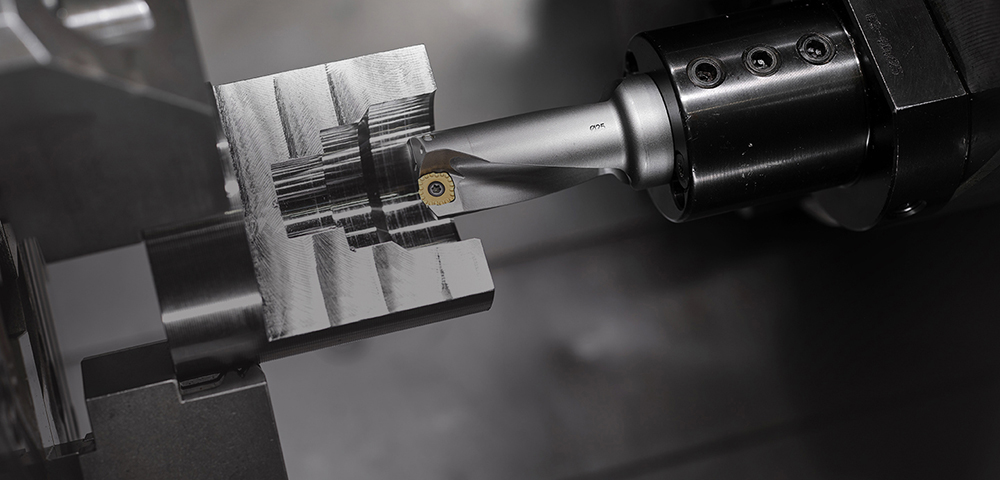

Kennametal Drill Fix Pro

For machine shops tackling a variety of holemaking jobs in workpieces of all shapes, sizes and materials, versatility is vital.

They need a tool that can adapt to an array of job requirements—and that’s exactly what Kennametal has delivered with its Drill Fix PRO indexable platform, an upgrade to the earlier Drill Fix line.

Indexable drills, which rely on removable inserts with multiple cutting edges, deliver a wider performance range at lower entry prices than solid drills.

While useful to heavily specialized industries, the Drill Fix PRO targets general engineering firms with diverse machines, equipment and processing capabilities. It can cut from 2 diameters (2xD) to 5 diameters deep and delivers hole diameters from half an inch to 2.5 inches.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *