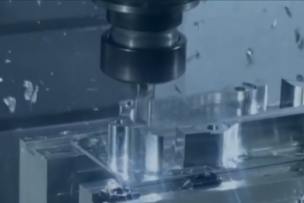

The optimized R shape geometry is designed to control chip flow direction to facilitate trouble-free chip evacuation. With this new feature, the ADO-TRS is able to significantly improve chip separation even in steel materials by breaking them into small pieces and consistent shape. In addition, this new geometry can reduce cutting resistance (thrust resistance) by as much as 30 percent versus conventional tooling, enabling it to outperform even 2-flute drills in high-feed processing with minimal cutting resistance.

The second key feature of the ADO-TRS is its wide chip pocket configuration.

In 3-flute drills, chips are difficult to be discharged from the center of the drill. The ADO-TRS employs a wide chip room flute geometry to improve chip ejection. Combined with the R gash specification, chips are curled for greater separation capability, which leads to smooth and stable chip evacuation.

Last but not least, the ADO-TRS is coated with OSG’s original EgiAs coating for high durability. The EgiAs coating consists of overlapping nano-periodical layers and wear-resistance layers, engineered to suppress the propagation of cracks that are likely to occur during drilling. The wear-resistance layer is composed of multiple hard layers, while the nano-periodical is a combination of hard and soft layers. With a mixture of hard and soft layers, internal stress can be relieved, allowing the EgiAs coating to achieve both high wear resistance and extreme toughness to ensure stable and consistent tool life under aggressive cutting conditions.

Cutting Data

1. Excellent Chip Formation and Evacuation in Steel Applications

Two of ADO-TRS’ most notable benefits are its superior chip management and low resistance drilling capability in steel materials.

SCM440 (raw) is one of the more viscous materials among steels. When processing this material with MQL, chips generated by conventional 3-flute drills and 2-flute drills are elongated as depicted in figure 2. As depicted in figure 3, the conventional 3-flute drill is unable to break chips into small pieces. As a result, remnants of elongated chips remain in the flute of the drill. The ADO-TRS, on the other hand, is able to demonstrate excellent chip form consistently as shown in figure 2.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *