Kennametal delivers productivity to customers seeking peak performance in demanding environments by providing innovative custom and standard wear-resistant solutions, enabled through our advanced materials sciences, application knowledge, and commitment to a sustainable environment.

Titanium is a highly valuable and sought-after material used in a wide range of industries, including aerospace, medical, and automotive. While it offers many benefits, such as excellent strength-to-weight ratio and corrosion resistance, it is also notoriously difficult to machine, making it a challenging material for many metalworking professionals. Here, you’ll discover 10 tips for machining titanium when milling, which can help you achieve better results and improve your productivity.

Tip #1: Benefits and Challenges of Machining Titanium

Titanium is a strong, lightweight metal ideal for a range of applications. However, it can be difficult to machine due to its high strength, low thermal conductivity, and chemical reactivity. Additionally, titanium can generate high temperatures and cutting forces during machining, which can cause tool wear and damage to the workpiece.

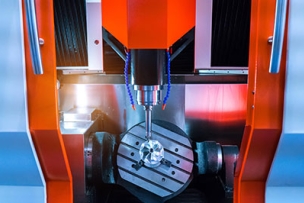

Tip #2: Quality Cutting Tools

When machining titanium, it is essential to use tools that are specifically designed for the material. Titanium is extremely hard to machine and can quickly wear down inferior cutting tools, resulting in poor surface finishes, tool breakage, and other issues. Look for cutting tools made from high-performance materials such as carbide, which can withstand the high temperatures and pressures generated during titanium machining. You should also choose tools with a high number of teeth to reduce the load on each tooth and prevent tool wear.

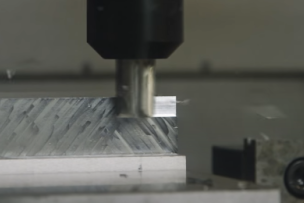

Tip #3: High-Speed Machining

High-speed machining techniques can be highly effective when milling titanium. This involves using high-feed rates taking lighter cut using dynamic paths to achieve optimal cutting conditions. By increasing the speed of the cutting tool, you can reduce the amount of heat generated during cutting, which can help improve surface finishes and reduce tool wear.

Tip #4: Radial Engagement

Radial engagement is an important factor to consider when milling titanium. This refers to the amount of the cutting tool that is in contact with the workpiece at any given time. When radial engagement is decreased, the surface speed can be increased to maintain the optimum temperature at the cutting point. By optimizing the radial engagement, you can improve chip evacuation and reduce the load on each tooth of the cutting tool, which can increase tool life and improve surface finish.

Tip #5: Effects of Thick-to-Thin Chip Formation

During machining, the thickness of the chips being produced can vary from thick-to-thin. This can have a significant impact on the machining process, as thick chips can cause problems with chip evacuation and tool wear, while thin chips can help reduce heat generation and improve surface finish. Understanding the effects of thick-to-thin chip formation is important when milling titanium, as it can help you adjust your machining parameters and achieve better results.

Climb milling, or thick-to-thin chip formation, is the ideal way to make sure you are getting the proper results. It begins with the cutting edge entering the excess material and exiting on the finished surface – meaning the cutter tries to climb over the material, ensuring that thick chips absorb cutting heat, decreasing adhesion from cutting pressure and the thin chip exits effectively. The exception to this is to conventional mill when you have an Alpha case in order to remove the thick hardened skin, shearing from the softer surface below to create a clean surface, and then revert back to climb milling once the skin is removed.

When dealing with thick-to-thin chip formation, it is important to pay attention to the chip breaker design on the cutting tool. A chip breaker is a groove or notch on the cutting edge that helps to break up the chips into smaller, more manageable sizes. A well-designed chip breaker can help to prevent these issues and improve overall machining performance.

Tip #6: Pay Attention to Arc In and Chamfer

Arc In is the steady entry of the tool into the workpiece, while chamfer is the angle at the cutting edge of the tool. Both factors can have a significant impact on the performance of your cutting tool when machining titanium. Make sure when machining to program thick-to-thin arc instead of a straight path which will help avoid sudden jarring changes in cutting forces. And program your chamfer to avoid unstable left-over materials.

Tip #7: Proper Coolant Pressure

Coolant pressure plays an important role in machining titanium. It is a difficult material and generates a significant amount of heat during cutting. Using high-pressure coolant can help reduce chip adhesion by flushing them away from the cutting area and cooling the workpiece and cutting tool. Additionally, using a chip conveyor or other means of automatic chip removal can further improve chip evacuation and reduce the risk of tool breakage.

Tip #8: Tool Wear and Deflection

Tool wear is a common problem when machining titanium. To prevent tool wear and damage to the workpiece, it is important to monitor your cutting tools regularly and replace them when necessary. You should also adjust your machining parameters if you notice signs of tool wear, such as poor surface finish or increased cutting forces.

Tool deflection can occur when the cutting tool bends or flexes during machining. This can result in poor surface finishes, tool breakage, and other issues. To avoid tool deflection, use cutting tools with a higher number of teeth, and consider reducing the cutting depth or width to reduce the load on each tooth of the cutting tool.

Tip #9: Making the Grade

Coatings and grades can be highly effective in improving the performance of cutting tools when machining titanium. Titanium nitride (TiN), Titanium Carbonitride (TiCN), Titanium Aluminum Nitride (TiAlN), Aluminum Titanium Nitride (AlTiN), and Aluminum Chromium Nitride (AlCrN) are common coatings for cutting tools, as they offer improved wear resistance and reduced friction. However, there are more advanced coatings that have multiple layers and provide more protection against chip building and tool wear. For example, high-performance solid carbide end mills used in aerospace applications can help you improve performance when machining titanium.

Tip #10: Adjust Feeds and Speeds

It's important to adjust your feed and speed settings to achieve optimal performance. Lower cutting speeds may be necessary to maintain a consistent cutting temperature when used on titanium. However, it's important to balance this with an appropriate feed rate to ensure that you achieve optimal chip evacuation and prevent excessive tool wear.

Bonus Tip: Seek Expert Advice

If you are new to machining titanium or are having trouble achieving the desired results, it is important to seek expert advice. Kennametal has experts who understand titanium and the tools used for machining it. By leveraging expert knowledge and experience, you can improve your machining results and avoid costly mistakes.

Bonus Tip: Secondary Relief

Secondary relief is an additional relief angle ground into the back of the cutting tool, which can help to reduce the risk of chipping or breakage, stabilize cutting edges and increase clearance. This can be particularly important when machining titanium, which can be highly difficult to work on. With todays advanced designs, you’ll find many tools utilizing eccentric ground edges specifically targeted toward titanium. These designs offer the proper clearance behind the eccentric relief. They are very effective and tend to feature a stronger edge and last longer. Kennametal’s HARVI™ III high-performance aerospace end mills are only one example of what is offered in the line.

Summary

Machining titanium can be a challenge, but with the right techniques and tools, you can achieve high-quality results and improve your productivity. By understanding the benefits and challenges of machining titanium, choosing the right cutting tools, using proper radial engagement and coolant pressure, monitoring tool wear, and seeking expert advice, you can optimize your machining process and achieve better results.

Previously Featured on Kennametal's blog.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *