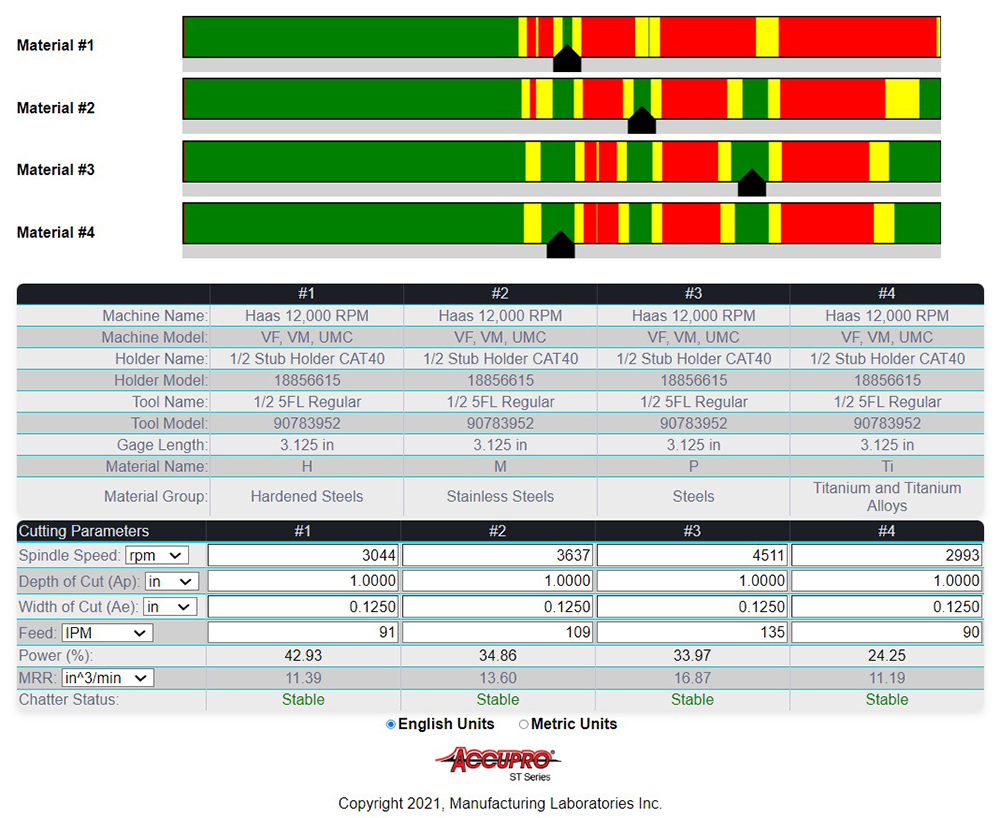

The dashboards utilize bar charts that display stable zones of spindle speed in green, unstable zones prone to error-inducing chatter in red and regions of uncertainty in yellow.

In many cases, machinists using traditional trial-and-error based on catalog or handbook values to find stability on a new setup might simply increase feed or speed until chatter begins, then slow down.

“That’s human nature,” Gomez says. “What they wouldn’t know is that if they had sped up a little more, they might have found another stable pocket for their assembly or material.”

Not only are the locations of stable zones nonintuitive, he says, they vary based on tools, assemblies and the type of material being machined.

“Until you can actually measure how that tool is behaving in your machine, you don’t know where these zones exist,” Gomez says. With the Accupro® ST Series, machinists can see a full range of zones before ever powering up their equipment by utilizing the online dashboard—access to which is included with the purchase.

Then, they “can start making parts right away,” Goettler explains.

“The more they do that in the course of a year, the more jobs they are able to process because they’re not spending time at the machine doing trial-and-error work,” he says. “They’re actually making parts.”

Such capability is particularly valuable for smaller machining and metalworking businesses competing with larger rivals that often have an advantage in budgets, staff and equipment.

“We know from history that it can take hours to identify stable operating speeds for many milling applications,” Goettler says. Devoting machinists, often the most skilled ones, to that process hinders productivity even more in a market that’s short of skilled labor to start with.

To eliminate that step, the Accupro® ST Series relies on the principles of the modal tap test used in MSC’s award-winning MillMax® service, which identifies optimal combinations of custom tooling-assembly setups.

Watch: How MSC MillMax Eliminates the Need for Trial-and-Error Setup

MillMax® has helped customers increase material removal rates an average 300 percent while slashing cycle time by an average 50 percent, rendering it particularly valuable to production facilities that may use a particular combination thousands of times a year.

What differentiates the Accupro® ST Series is that it provides that kind of optimization data from an off-the-shelf tooling assembly, making the technology more accessible to job shops where metals and tool-holder-machine combinations may change week to week, day to day and even hour to hour

‘The Luxury of Choices’

The Accupro ST Series assembly — and the accompanying dashboard — help eliminate costly trial and error associated with new job setups, Goettler says. Because the dashboard reveals ideal, stable operating speeds and feeds, the shop can begin making revenue sooner.

Knowing those stable speeds and feeds can also assist with providing precise quotes on prices and lead times to current and prospective customers. With the range of toolholders, end mills and retention knobs available, customers are able to reconfigure Accupro® ST Series milling assemblies as required. Those adjustments are enabled by Accupro®’s easy-to-use online product selection tool, which highlights the tools necessary for different materials.

In essence, Gomez says, the tool “serves as a dashboard configurator showing the secret-sauce recipe for their unique machine and assembly combinations.”

Once Accupro® ST Series users examine the range of stable operating zones, they can decide whether they want to prioritize speed, surface finish, repeatability or tool life based on the unique needs of their businesses.

If a supply-chain disruption has delayed delivery and a business wants to complete the order as soon as possible, it might choose the highest speed even though doing so reduces tool life, Goettler says.

“The really great thing is that the user has the luxury of choices,” he adds. “They have options to consider instead of relying on the first stable performance region they find.”

How could the Accupro® ST Series help your business become more competitive? Tell us in the comments below.

Talk to Us!

no subject

25Leave a reply

Your email address will not be published. Required fields are marked *