Video Transcript

MICHAEL GOMEZ: Back when it started, Accupro was primarily focused, let's say in drilling and kind of some very fundamental milling applications. Today, we're taking a big step by incorporating this new indexable line. So that indexable line includes turning, grooving and milling tools, which are all unique in their own way.

Narrator: This video is brought to you by Accupro, putting the science of machining dynamics at your fingertips. If you're looking for real world insights, tips from leading industry experts, the latest trends in products and technology, you've come to the right place. From MSC Industrial Supply, this is Tooling Up.

TONI NEARY: Hello and welcome to Tooling Up. I'm your host, Toni Neary, and I'm so glad that you've joined us for what's going to be a great episode. If you're watching for the first time, go ahead and click that like and subscribe button. You don't want to miss a single episode. Today I'm excited to be talking about Accupro indexable tooling and we have Michael Gomez.

He's the principal R&D engineer at MSC Industrial Supply. Michael, thank you so much for joining us today, and welcome to Tooling Up.

MICHAEL GOMEZ: Thank you Toni, thanks for having me on. I'm really excited today to talk about Accupro Indexables. So, looking forward to the conversation.

TONI NEARY: Perfect. And I always like to jump in and know a little bit about how people end up in their careers. So if you don't mind, tell us a little bit about yourself and how you came to work at MSC.

MICHAEL GOMEZ: Absolutely. So I'm one of those late bloomers that didn't know I wanted to be in manufacturing until maybe my junior or senior year of college. So I started out over at the University of North Carolina at Charlotte, where I studied mechanical engineering. Transferred over to the University of Tennessee for graduate school, where my main focus was, again, in this kind of machining science and machining dynamics area of study, and then I recently joined MSC roughly about two years ago, now leading a manufacturing research and technology team here, where we really work to take technology, what I like to say is take technology outside of the lab and into the customer's hands.

TONI NEARY: All right, a late bloomer, and you've already got a PhD. So I'm impressed. And I think you're being slightly humble, because I also believe you were acknowledged as one of SME's 30 under 30. Tell me a little bit about that.

MICHAEL GOMEZ: Yeah, absolutely. So I was honored to be selected kind of in SMEs recent 30 under 30 award program. Of course, an amazing group of individuals there. And of course, I'm just one of them, you know, as part of an amazing team, but effectively, I was honored in that award just for some of the work I had done back when I was in college around taking some technology that's usually prohibitively expensive and being able to to deliver to your kind of average Joe or everyday person or really anybody, you know, in a lab.

Hey, here's a new technology that can help you make parts better, understand your machining operations, and then, of course, utilize what I'm really passionate about, which is machining dynamics, in a way that sometimes they don't really think about. But definitely you can deliver in a nice and easy way.

TONI NEARY: So some of our viewers are already familiar with Accupro, but for those that aren't in the know, tell us a little bit about Accupro.

MICHAEL GOMEZ: So Accupro is a brand started at MSC in around 1996, and exactly as you mentioned, it's really become synonymous with cost effectiveness yet high-performance cutting. And so ultimately it's a solution that we can deliver to customers through our team of metalworking specialists. So it's a really unique product for MSC to promote, because we have a metalworking specialist team that likes to work at the spindle.

So typically you can suggest a solution and a lot of times Accupro is the solution that our customers turn to due to that affordability yet reliable performance.

TONI NEARY: Tell us a little bit about the new indexable tooling line, because I feel like there's some groundbreaking technology at work here.

MICHAEL GOMEZ: Back when it started, Accupro was primarily focused, let's say in drilling and kind of some very fundamental milling applications. Today, we're taking a big step by incorporating this new indexable line. So that indexable line includes turning, grooving and milling tools, which are all unique in their own way. There's a lot of really unique chip breakers that we've included in our product offering.

Additionally, we have a really nice insert classification system. So I know a lot of times when customers are going and picking the right cutting tool for their application or looking for a solution, you have to kind of wade through. Oh, wait a minute, what is what is this insert classification mean? So in this case, all of our inserts start with an AC.

You know, A being Accupro, C being carbide. And then what makes it really easy to identify the correct insert is through the next I'd say three components. The first being the material group. So we'll use P example. So that's an ISO material group that stands for steels. The next number is the ISO hardness. So a lot of times when we run into customers they like to classify their metalworking operations, sometimes through the hardness number.

So the next one we'll say is ISO 15. And then of course the last number is a secondary application. Because we always like to use cutting tools that have more than one use. They can have a really great tool in one material, but at the end of the day, what I really want is that versatility in a different material.

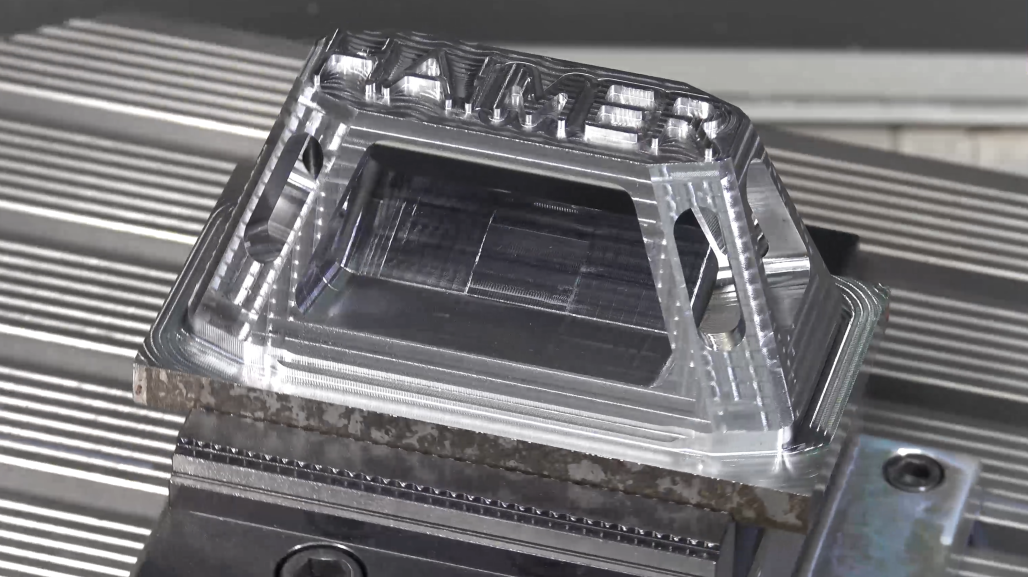

So that's one nice innovation that we've had that at least lets you classify the inserts. That applies to all of the new indexable line. The next one we'll take a quick look at is milling. And what some of those milling inserts have is a really

And so traditional geometries, you kind of have a theoretical equation you can use to calculate roughness.

And that's when my cutting tool only has one radius at the edge. Well what ends up happening is that we have multiple radii at the edge. And so what happens is you end up getting this really nice surface finish running the same speeds that are twice as better as a traditional insert. So that's one really nice feature that we've been able to incorporate with these inserts.

And then of course we have our grooving inserts. And these grooving inserts can both do groove turning and parting just depending on what your application is. It has a very similar insert classification system. But what I can say is I've used these tools myself on the shop floor here, and they've performed amazing.

TONI NEARY: And I would imagine through part of your R&D process you're also researching and you've got all of the data and analytics to show this is the exact tool you should use for the exact application to save you time and money.

MICHAEL GOMEZ: Yeah. And so of course, we've kind of pitted up our new Accupro indexable line with some of the most popular choices in the market. And so when we do that, what we notice is that there is superior performance with what we're delivering into the market. And that's really important for us, right. So I'll go back to the kind of themes of Accupro early on, which is high performance and affordability, and you have to balance that too.

And a lot of times some people say, well, wait a minute. Those seem like, you know, counter, counter points or counter ideas. How can it be affordable yet high performing? But that's something that we really, really spend a lot of time to, to prove to ourselves first that I trust this solution. We know the solution will perform in the marketplace.

And then, of course, how do I train our metalworking specialist team to maximize the performance of these cutting tools? And so what's really nice about this indexable line is that it optimizes the performance and increases capabilities of inserts, in a wide variety of sizes to cover a wide variety of applications.

TONI NEARY: All right, Michael, I feel like I've learned so much today. And I love just, you're brilliant. And the way that you bring all of this information to share with us just makes it so understandable. So now I kind of want to know, how do you get better than this? What's, what's happening behind the curtain right now with the Accupro team?

MICHAEL GOMEZ: Yeah, absolutely. So again, there's a repeating theme here, which is we love to take technology from the lab and put it into the customer's hands. And so what I'll say is, because we're in a lab space, we invest a lot in R&D where we're always trying to push ourselves to be better. And a lot of times we work with our customers to figure out, you know, what should we be working on right? We don't make these decisions in a vacuum, and we know where kind of the customer demand is and where they want, you know, they want to see their products. And so really at the end of the day, it's about maximizing efficiency and productivity for our customers. And so today you know we're doing that through cutting tools. But then we can think about how do we combine those cutting tools with some of the really cool and neat things that you, you learn about in machining dynamics or trying to utilize the physics of the machine tools, and then you have a really, really cool solution, that I think can be really transformative in the industry.

TONI NEARY: Well, Michael, you have absolutely piqued my interest, and I can't thank you enough for taking the time to meet with us today. And this has been informative and exciting, and your passion is just contagious.

MICHAEL GOMEZ: Awesome. Thank you so much for having me. We're really excited and look forward to learning more.

TONI NEARY: It was great hanging out with Michael Gomez of MSC Industrial Supply today, and if you enjoyed our conversation as much as I did and you don't want to miss future discussions, go ahead and like this one and subscribe to our channel. To find out more about Accupro Indexable tooling, visit www.mscdirect.com/accupro.

Thanks so much and we'll see you next time on Tooling Up.

Narrator: What more insights and ideas to improve the efficiency and productivity of your operations? Check out the Tooling Up video playlist to hear tips that can take your company to the next level. And subscribe to our channel so you won't miss out.