In-process tool checks provide real-time feedback on the condition of your cutting tools and can identify and compensate for things like tool wear and thermal effects.

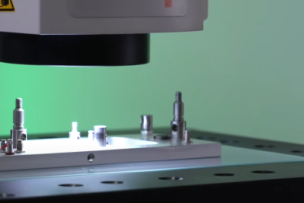

Determining the geometric information and the condition of your cutting tools is fundamental to manufacturing quality components. In-process tool checks provide real-time feedback on their condition and can identify and compensate for things like tool wear and thermal effects. Left undetected, such events can result in excessive rework or even scrap parts. Learn about the benefits of in-process tool setting in the short video above (music only, no transcript).

Previously Featured on Renishaw's YouTube channel.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *