Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

The CoroDrill® DS20 from cutting tool and tooling system specialist Sandvik Coromant is the first indexable drill concept capable of producing hole depths up to 7xD.

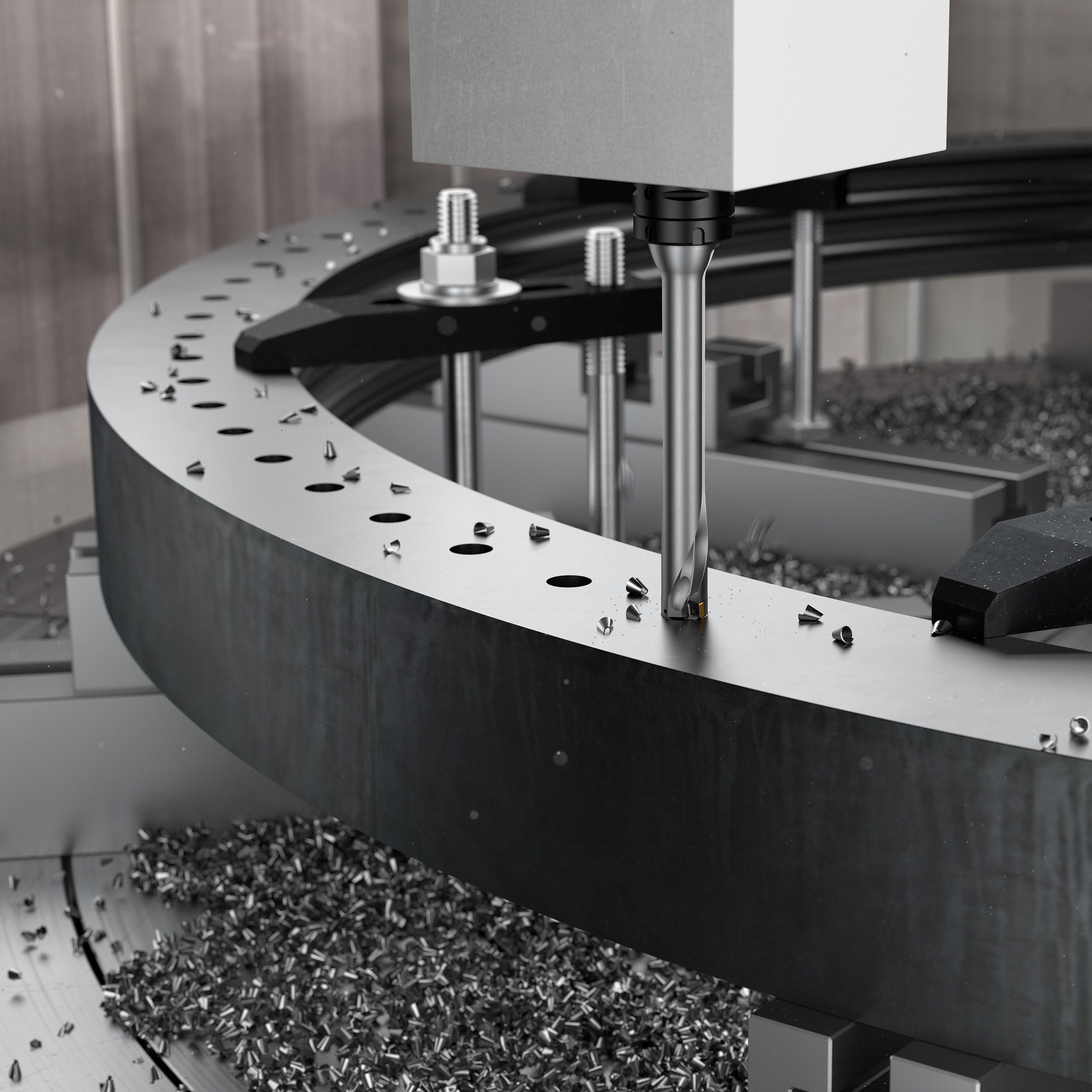

The CoroDrill® DS20 from cutting tool and tooling system specialist Sandvik Coromant is the first indexable drill concept capable of producing hole depths up to 7xD. The drill, which includes completely new designs for both the body and inserts, provides users with reliable, predictable chip control and outstanding penetration rates in all 4–7xD applications.

Replacing the existing CoroDrill 880 and CoroDrill 881 tools, 4–5xD CoroDrill DS20 indexable drills provide tool life improvements of up to 25% and productivity gains up to 10%, depending on workpiece material. The 6–7xD variants represent an entirely new capability range of indexable drills from Sandvik Coromant. To complement the introduction, the company is releasing a new Modular Drilling Interface (MDI) that acts as a coupling between the drill and adapter. Available in Coromant Capto® and HSK shank types, the MDI provides high precision, excellent centering capabilities and reduced tool inventory. Watch the short video below to see the CoroDrill DS20 in action.

CoroDrill DS20 indexable drills are both versatile and cost-efficient, increasing tool life and productivity in nearly all workpiece materials compared to current best-in-class concepts. No pilot drilling is needed.

“Among the most important factors when drilling to depths of more than 5xD are controlled cutting forces, secure chip evacuation and high centering capabilities,” explains Håkan Carlberg, Senior R&D Engineer, Indexable Drilling, at Sandvik Coromant. “Going from a 5xD to a 7xD drill, the theoretical difficulty increases approximately threefold due to an increased inclination to bend. Designing the CoroDrill DS20 7xD drill required careful consideration of around 50 parameters that all depend on each other. The outcome is improved process security through lower forces and lighter cutting, particularly at entry. In turn, users achieve lower cost per hole, the ability to drill deeper and reduced sound levels.”

The drill body is strong and fatigue-resistant with higher levels of stiffness than ever achieved before, while chip flute shapes are individually designed for each drill size and insert. This combination of factors leads to less vibration, predictable wear patterns and increased tool life. In addition, next-generation “double-step” technology reduces entry cutting forces by up to 75% compared to CoroDrill 880 tools, improving centering capabilities. Strong insert design and bulk strength provide extra toughness, with four true cutting edges on both center and peripheral inserts.

Regarding the new MDI, double centering with high fitting accuracy enables good run-out precision and optimal repeatability. Here, flange and surface contact between the drill body and nut provides increased stability and promotes hole quality. One size can be used for several drill diameters.

CoroDrill DS20 indexable drills are initially available in diameters .591 to 1.575 inch (15 to 40 mm) with a selection of shank types, insert sizes, grades and geometries to suit all material types and applications, including those found across the general engineering, automotive, oil and gas, pump and valve, and aerospace sectors. Additional diameters up to 2.559 inch (65 mm) will be added to the program.

Download the brochure from Sandvik Coromant to learn more about the CoroDrill DS20.

Brought To You By

More from Sandvik Coromant

More on Innovate

It’s been said that necessity is the mother of invention, but sometimes a more proactive and collaborative approach is required, especially when it comes to manufacturing innovation.

In this episode of MSC's Tooling Up, Toni Neary is joined by Brendt Holden, President of Haimer for a discussion on their innovations in shrink fit technology.

In this episode of MSC's Tooling Up, Toni Neary is joined by Jergens Vice President Matt Schron and Product Manager Mike Antos for a discussion on the 5CV Self-Centering Vise.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *