Seco is one of the world’s largest providers of comprehensive metal cutting solutions for milling, stationary tools, holemaking and tooling systems. For over 80 years, we have been more than just a cutting tool provider. We develop and supply the technologies, processes and supports that manufacturers depend on to maximize productivity and profitability.

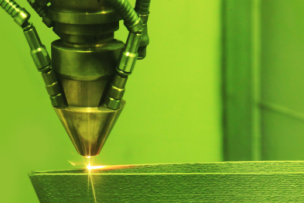

Additive manufacturing, or 3D printing, allows Seco Tools to create products that would otherwise be difficult or impossible to manufacture. The advantages include shorter lead times, improved tool life and increased sustainability.

The development and manufacturing of prototypes for metal-cutting machining via additive manufacturing (AM) is becoming increasingly commonplace in the operations of Seco Tools. AM allows Seco to make custom tools and solutions for their customers that are difficult to achieve through conventional manufacturing, especially when it comes to complex geometries.

Other customizations examples include making the tools lighter, which improves vibration-dampening properties, or providing better cooling options. “By directing the coolant to hit the core of the cutting edge, we can significantly extend tool life. With AM technology, coolant can be guided to locations that would otherwise have been impossible” explains Ingemar Bite, R&D Specialist at Seco Tools. He also believes that AM technology helps shorten lead times. “AM allows us to produce geometries that require less manufacturing steps, which often results in shorter lead times and therefore faster deliveries”.

Increased Sustainability

AM technology will open up the possibility of repairing broken tools in the future, by removing dysfunctional components and printing them anew. This could also involve re-using different types of machine-side connections. Overall, AM technology creates less waste of materials and any leftover powder can be re-used.

AM could be a time-efficient and cost-effective method for one-of-a-kind production and prototype development. However, it could also be an excellent way to manufacture standard products in large volumes. Seco Tools is already manufacturing cooling clamps for its Jetstream product line via 3D printing.

.jpg?itok=clvY6OP5)