Technical Insight: OSG AE-VTSS

Sliding head lathes are highly accurate multi-axis CNC machines that provide a single setup solution for complex processing.

Sliding head lathes are highly accurate multi-axis CNC machines that provide a single setup solution for complex processing.

By Kotaro Niimi, OSG Corporation Applications Engineer (End Mill Development Division)

In the world of manufacturing, efforts are constantly being made to reduce costs. In addition to high efficiency and long tool life, ability to achieve unattended machining with minimal operator input has also become a highly sought quality in cutting tools in recent years.

Sliding head lathes are highly accurate multi-axis CNC machines that provide a single setup solution for complex processing. They especially excel at producing parts of the same shape with great efficiency and stability. With capabilities to finish delicate parts in one setup and quicker job cycle than traditional fixed head machines, sliding head lathes are one of the best equipment for unattended machining with little or no human intervention.

End mills used in sliding head lathes are generally used for slotting and D-cutting (frontal milling). In spring 2022, OSG has released the AE-VTSS carbide end mill with optimized specifications that contribute to unattended machining operations in sliding head lathes.

1. Superior Cutting Chip Control

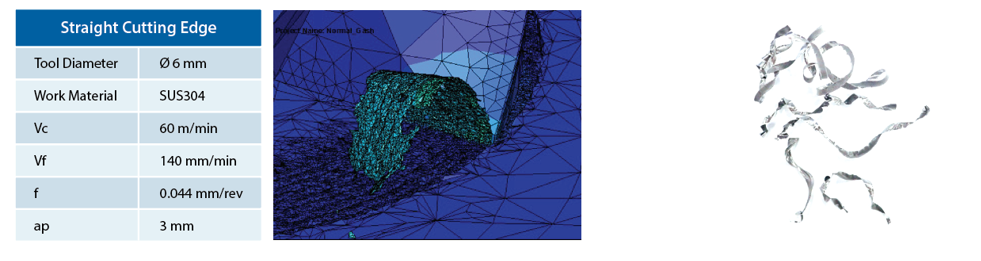

Even if the material removal volume per part is small, chip trouble is likely to arise as the number of work pieces increases. Figure 1 depicts long and distorted cutting chips created by an end mill with conventional (straight) cutting edge geometry from plunging in SUS304. These inconsistent chips may wrap around the spindle as the machining continues. If the cutting chips become tangled around the spindle, the machine must be stopped for chip removal, which leads to reduced productivity.

Figure 1. Cutting chips created by an end mill with conventional (straight) cutting edge from plunging in SUS304.

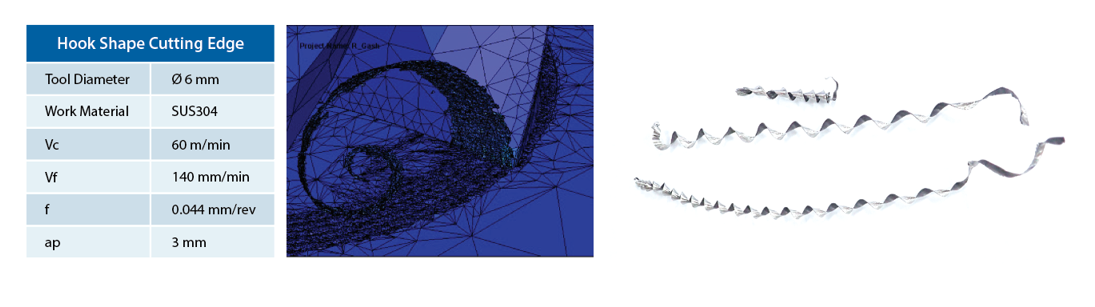

Figure 2. Cutting chips created by the AE-VTSS end mill with hook shape cutting edge from plunging in SUS304.

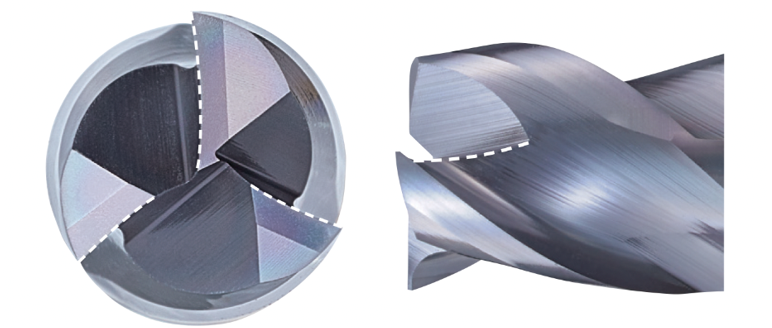

OSG’s AE-VTSS is engineered with an original bottom cutting edge hook shape (PAT. P. in Japan) that contributes to the creation of stable chip shape and improves chip evacuation. The bottom cutting edge of conventional end mills are generally straight, but the AE-VTSS is designed with a bow shape from the outer peripheral side that leads to the center as illustrated in figure 3.

Figure 3. AE-VTSS’s 3-flute specification and bottom cutting edge hook shape.

During product development, cutting simulations were used extensively to determine the optimal specifications of the hook shape. Figure 1 depicts chip generation with a conventional (straight) cutting edge. In contrast, figure 2 illustrates chip generation by the hook shape design. Comparing the two, the hook shape produces chips with stronger curl. In fact, as demonstrated in figure 2, the hook shape produces curled chips in a stable manner, which minimizes chip evacuation troubles such as the tangling of chips with the cutting tool.

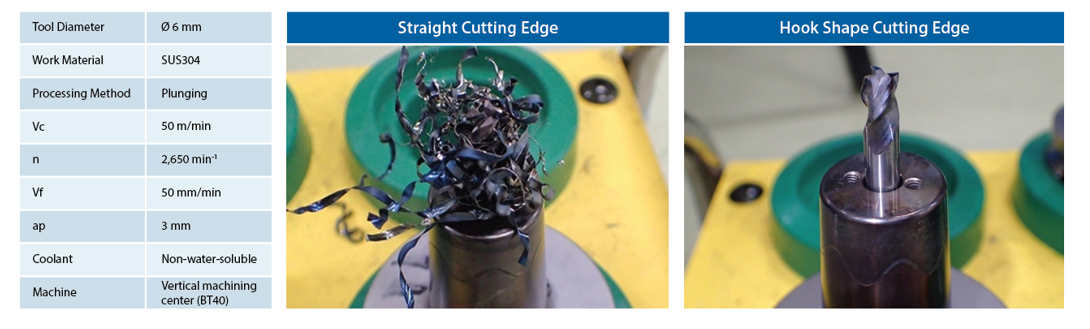

In a cutting trial, the straight cutting edge end mill and the AE-VTSS end mill with hook shape cutting edge are compared by plunging 37 holes continuously. As depicted in figure 4, cutting chips are wrapped around the straight cutting edge end mill whereas the AE-VTSS with hook shape cutting edge is chip trouble-free. As demonstrated in this cutting trial, the AE-VTSS’s hook shape cutting edge effectively suppresses chip evacuation troubles to contribute to stable and uninterrupted machining.

Figure 4. Condition of end mills after plunging 37 holes in SUS304.Cutting chips are wrapped around the straight cutting edge end mill whereas the AE-VTSS with hook shape cutting edge can continue to be used.

2. Multi-functional

The number of cutting tools that can be attached to a sliding head lathe is limited. Taking this characteristic into mind, the AE-VTSS is developed as a multi-functional 3-flute end mill that excels in plunging, slotting and side milling. The multi-functionality of the AE-VTSS contributes to the consolidation of machining processes, reduction of setup time, and tool change time to maximize the performance of sliding head lathes.

3. Variable Lead Geometry to Suppress Vibration

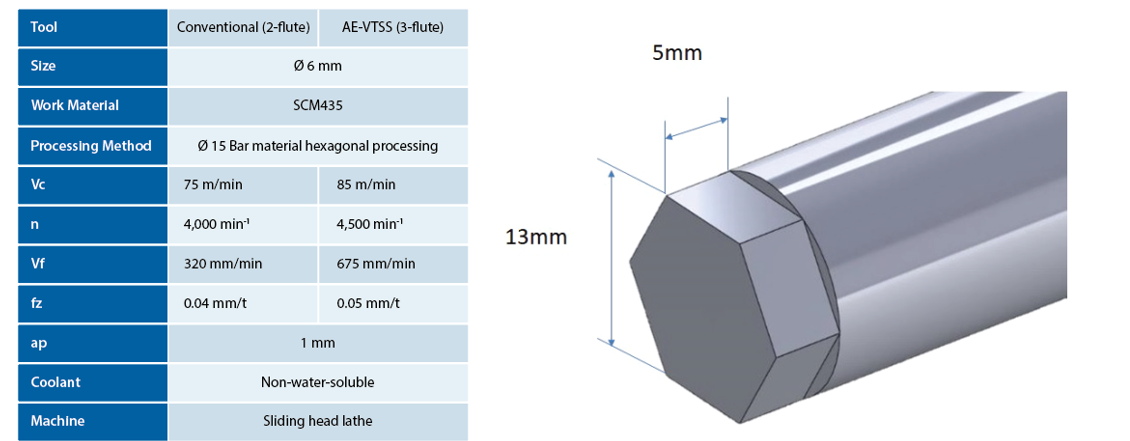

In a sliding head lathe, the workpiece is usually clamped into position by a chuck. Compared to clamping in CNC machining centers, machining with a sliding head lathe has lower rigidity and is more prone to chattering. Figure 5 illustrates a cutting trial between a conventional 2-flute end mill and the AE-VTSS. Chattering and burrs occurred after 2,000 passes with the conventional 2-flute end mill. The AE-VTSS, on the other hand, exhibits stable performance, good machined surface with no burrs even after 3,000 passes at a more aggressive cutting condition. OSG’s AE-VTSS’ unequal spacing of teeth and variable-lead geometry have effectively minimized chattering to enable stable and high-efficiency milling even in a setup with low rigidity.

Figure 5. Cutting condition and work shape image of a cutting trial between a conventional 2-flute end mill and the AE-VTSS 3-flute end mill.

4. Tool Geometry Optimal for Sliding Head Lathes

Space inside the sliding head lathe is limited. Depending on the positioning of the tool changer and workpiece, sometimes a cutting tool cannot be used as is based on its overall length.

During the development process of the AE-VTSS, sliding head lathe manufacturers were surveyed regarding the optimum overall length of end mills. Based on this feedback, the AE-VTSS is designed to feature an overall length of 50 mm or less.

5. DUARISE Coating for Long Tool Life

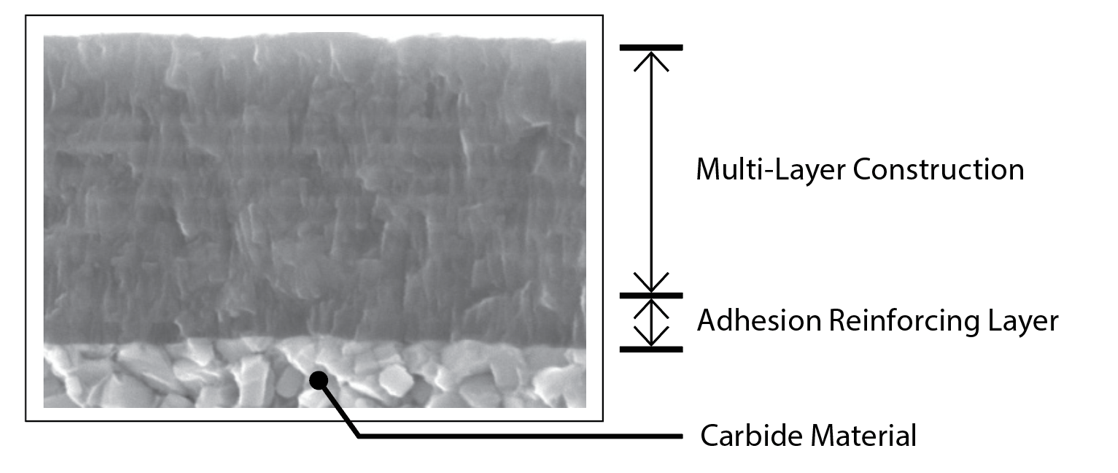

The AE-VTSS end mill employs OSG’s DUARISE coating with excellent lubricity, wear resistance, superior friction-resistance and high oxidation temperature qualities.

Figure 6. Composition of OSG’s DUARISE coating.

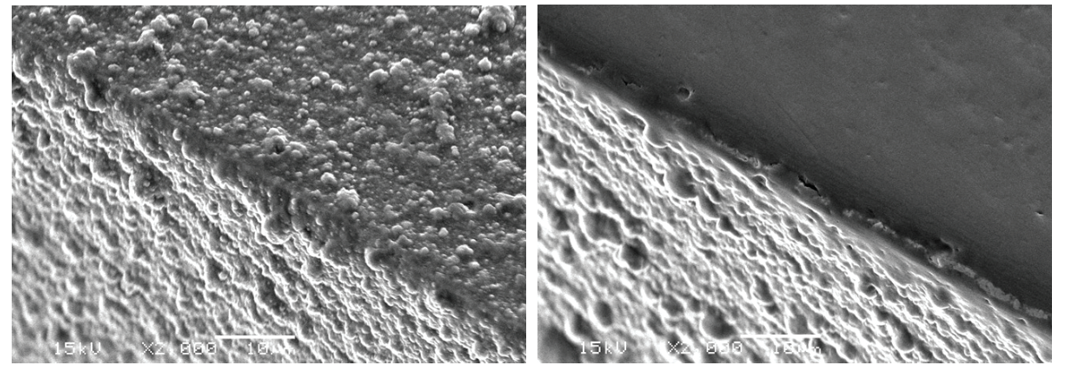

Figure 7. From left, conventional coating and the DUARISE coating.

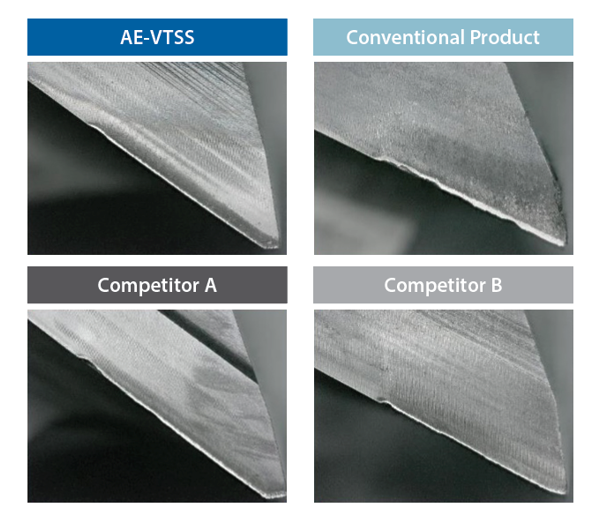

The DUARISE coating is composed of a heat-resistant layer, a low-friction layer, and an adhesion reinforcing layer as depicted in figure 6. Its multi-layer construction suppresses thermal cracks to prolong tool life. The surface of the coating is smoothed to remove granular irregularities called droplets to improve the quality of the machined surface as illustrated in figure 7.

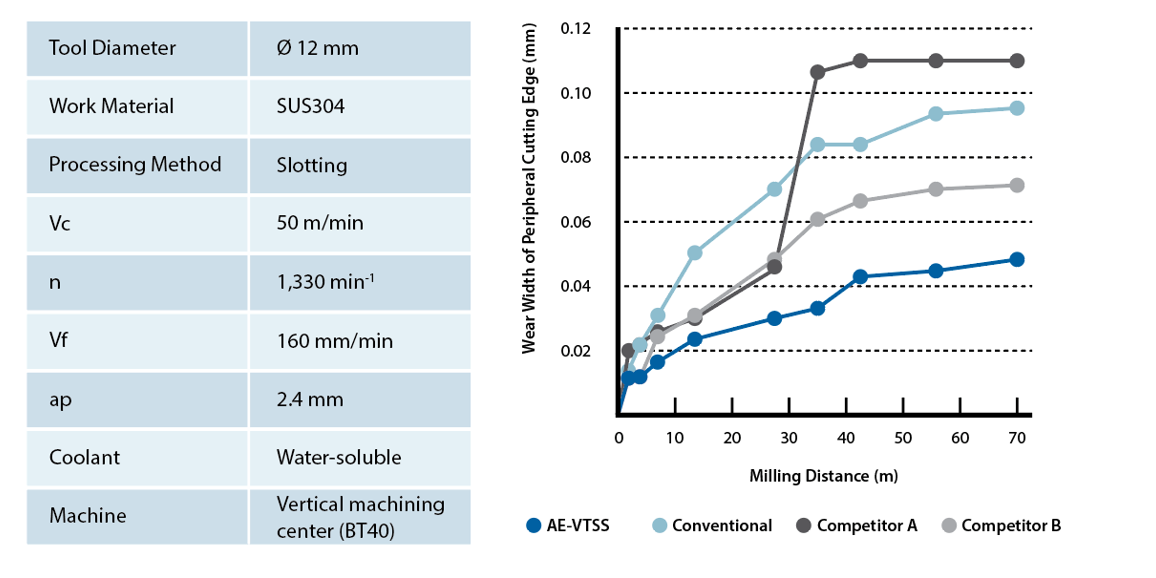

Figure 8. Wear resistance comparison

Figure 8 illustrates the superior tool life of the AE-VTSS. In the cutting trial, wear wide of the peripheral cutting edge by four end mills are measured after milling 70 m in SUS304. The AE-VTSS demonstrates high durability with minimal wear whereas the other end mills exhibit significantly greatly wear.

The AE-VTSS is one of OSG’s latest milling innovations optimally designed for sliding head lathes to achieve efficient, precise, and repeatable stable cutting of unattended machining over long periods to reduce production costs. The AE-VTSS is designed to support a wide range of milling operations in stainless steel, cast iron, carbon steel, alloy steel and hardened steel (up to 40 HRC). The new offering is available from diameter 3 mm up to 12 mm, with a total of seven items, and will continued be expanded to better fulfill evolving needs.

Previously Featured on OSG's blog. Browse cutting solutions from OSG on MSCDirect.com.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.