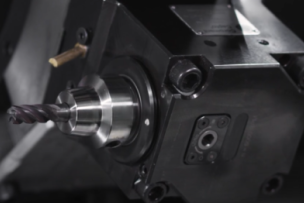

Challenge: Vibration and its consequences – slower production, poor surface finish and short tool life – often limit the performance of long milling tools.

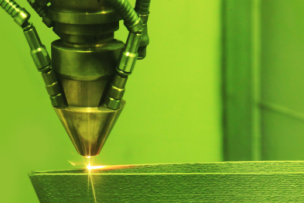

Solution: Additive manufacturing offers a new way to reduce the weight of a milling cutter by 80 percent for significantly better performance and up to 200 percent increased productivity, in combination with the Silent Tools™ damping technology.

The combination of complex component features with deep cavities in demanding materials is a typical milling challenge in aerospace and oil and gas applications. The long overhangs that these applications require often cause a bottleneck due to vibration problems and related performance issues.

Sandvik Additive Manufacturing, a new division established within the Sandvik Machining Solutions business area in 2017, has looked into new ways to tackle this challenge. The result, offered by Sandvik Coromant, is the new lightweight CoroMill® 390 milling cutter combined with dampened Silent Tools™ holders.

The main goal was to decrease the weight of the cutter to improve the performance at long overhangs. Several alternatives were available, such as using a lighter material or machining holes in the tool body, but additive manufacturing turned out to offer the optimal solution in this case.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *