Stronger Together: Help Increase Welding Productivity Up To 40%

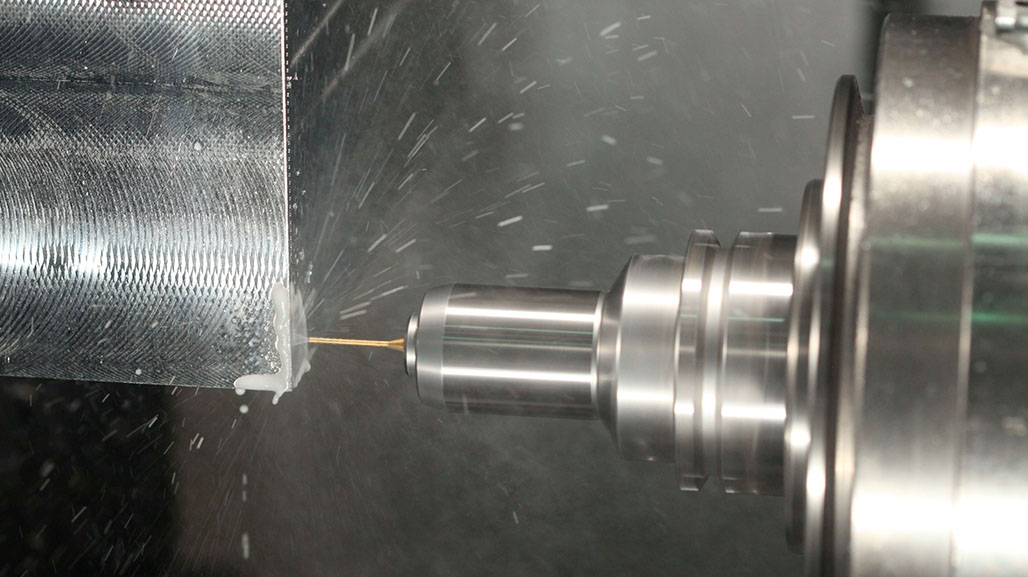

Reduce your downtime, increase your throughput, and keep your operation lean. Sparks fly when a technician uses the 3M Electric Angle Grinder and the 3M Adflo PAPR to smooth out a metal surface in this short video.