How Machinist Apprenticeship Programs Can Help the Skills Gap

Companies and their partners can use registered apprenticeship programs to develop and retain a skilled labor force.

Companies and their partners can use registered apprenticeship programs to develop and retain a skilled labor force.

The need for skilled workers in manufacturing will only grow as baby boomers begin to retire. Apprenticeship programs can tap into older employees serving as mentors before retirement hits, helping to build a new generation of skilled workers.

Registered apprenticeship programs can take several forms, with flexible requirements and learning options.

Companies can partner with a variety of entities to create an apprenticeship program, including other businesses, government groups, not-for-profits and academic institutions.

The skills needed by a company should be built into the framework of an apprenticeship program’s standards. And once the program has been created, a clear communications plan should make sure it’s publicized inside and outside the company.

Finding skilled workers can be a challenge, especially in a manufacturing environment. John Hindman, director of learning and performance improvement at Tooling U-SME, recently hosted a webinar to discuss how apprenticeship programs can help companies develop and retain a skilled workforce.

Traditional machinist apprenticeship programs have always meant learning while on the job. John Hindman, director of learning and performance improvement at Tooling U-SME, says apprenticeships have been around since at least the 1600s, when they were a form of indentured servitude. Today, he says, there are a half-million registered apprentices in the U.S. Unlike apprentices of old, though, modern apprentices often combine on-the-job learning with classroom and independent study.

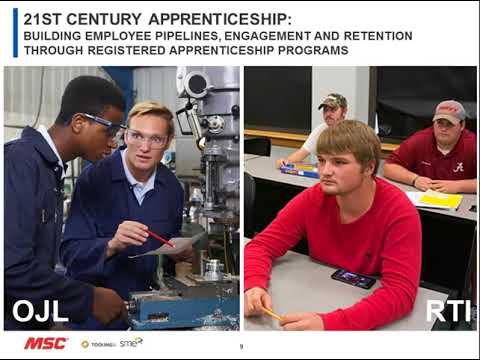

Hindman discussed apprenticeships during a webinar from Tooling U-SME and MSC’s Better MRO, “21st Century Apprenticeship: Building Employee Pipelines, Engagement and Retention through Registered Apprenticeship Programs.”

“Today’s apprenticeship programs act as an earn-and-learn model, where current employees typically spend normal workdays learning their craft at the workplace and then take educational curriculum during off-work hours,” says Hindman. “This allows for apprentices to take the knowledge they are learning and apply it to the job through a structured on-the-job learning experience.”

According to the U.S. Department of Labor, apprenticeships are offered in more than 1,000 career areas, covering occupations ranging from healthcare and hospitality to transportation, construction and advanced manufacturing.

Data from the U.S. Labor Department shows that as of March 2018, approximately 391,000 U.S. manufacturing jobs remained unfilled. With more and more skilled workers nearing retirement, creating what some call a “Silver Tsunami,” the problem will only grow, says Hindman.

“Now is a critical point in time where apprenticeship programs can build a pipeline of skilled workers to offset the losses looming during the baby boomer retirements,” he says. “Some baby boomers are still on the floor and available to provide critical hands-on mentoring for apprentices, but they won’t be for long. Thousands of hours of on-the-job experience are part of an apprenticeship program, so these mentors are extremely important to passing down a company’s organizational knowledge and tricks of the trade.”

Machinist apprenticeship programs cannot only recruit new workers but also help companies retain the workers they already have. In its 2018 Retention Report, the Work Institute notes that the top reason cited by those who voluntarily resign a position is a lack of career development opportunities.

Hindman says apprenticeship programs help address this by creating job security and career pathways—clear steps to higher skills and pay. “As you learn and meet key milestones of the program, wage increases are in place that align with skill development,” he says.

In addition to more pay, employees who successfully complete a registered apprenticeship program receive a nationally recognized credential.

Did you know there is a new generation already working in the industry today? Who are they and how did they discover manufacturing? Read “They’re Already Doing It: The Millennial Machinists Helping the Skills Shortage.”

Registered apprenticeships have to meet certain standards, but they can be customized to meet business needs, says Hindman.

“The frameworks for apprenticeships provide occupational-specific curriculum guidelines and on-the-job performance standards that demonstrate job competency in your workplace,” he says.

Typical requirements for a two- to four-year machinist apprenticeship program registered with the U.S. Department of Labor include:

2,000 hours of on-the-job learning per year in job processes as laid out in the apprenticeship standards established by the employer

144 hours of education or related training instruction (RTI) per year

“However, depending on how you register your apprenticeship program, you may not need to have apprentices go through all of those required hours,” says Hindman.

Time-based apprenticeships go strictly by the hourly requirements. But two other options allow companies to create a program tailored to their goals. Competency-based programs allow apprentices to reduce their on-the-job learning hours by demonstrating that they already have the required skills for certain aspects of a job. A hybrid program has a time-based requirement but also allows workers to defer hours by proving competency.

Registered apprenticeship programs can also be flexible in terms of the related training instruction, Hindman says.

Employers often partner with educational institutions—such as community colleges or universities—to offer classroom instruction. But online learning is now accepted, making classes more accessible to employees and also making programs more feasible for companies without a community college or university nearby.

Hindman says employers can also create their own educational programs, contracting with instructors to offer classes on-site. Some programs are also engineered to provide college credits to participants, or to allow recent college graduates to use their degrees to offset part of the RTI hours.

For companies who don’t want to go it alone, launching an apprenticeship program with partners can offer valuable benefits, Hindman says, including offering insights into best practices of other partners. “They can accelerate program development, increase the number of program participants or reduce costs through grants and leveraging of resources,” he says.

Partners can include academic institutions, company coalitions, public entities and labor market intermediaries. Company coalitions could include companies in the same industry that have similar workforce needs, or companies in the same region looking to build a stronger local workforce. Public entities include government institutions at the local, state or federal level. Labor market intermediaries are typically not-for-profit groups—such as professional organizations or the local chamber of commerce.

Hindman encourages companies to reach out to potential partners.

“Apprenticeship programs are being adopted for large, medium and small companies,” he says. “So whether you need one apprentice or one hundred apprentices, there is a program for you.”

How are manufacturers recruiting new talent beyond apprentice programs? Learn how one company is leveraging its local resources in this interview article “Q&A: How to Recruit, Train and Retain Top Machining and Manufacturing Talent.”

Registered apprenticeship programs are industry-driven—businesses can create programs that meet their unique needs, integrating current training practices and employee development strategies. That means each program creates its own standards.

“When writing your standards, ensure the skills needed for your business are built into the framework,” Hindman advises. “Make sure that there is alignment between the education and the job activities that you hold workers accountable to each and every day.”

Hindman says it’s also important to make sure mentors are both qualified and able to teach others. “This will go a long way in verifying the skills are taught consistently and through good practices in adult learning theory,” he says.

Finally, businesses need to create an internal and external communication strategy.

“The outreach will not only demonstrate potential growth within your company but will also market to the local community that you have careers available for long-term employment,” Hindman says. “Your current employees will appreciate the career development opportunities, and you will attract more candidates for future openings.”

Does your company offer an apprenticeship program? If not, would you try one? Let us know.

Registering an apprenticeship is the process by which an employer or other apprenticeship sponsor shows that their program meets national quality standards. Programs can be registered with the Department of Labor or with a federally recognized state agency. Registered programs may qualify for state tax credits and have access to federal resources.

Want to learn more about registered apprenticeship programs? The Department of Labor offers links to federal resources, a quick-start toolkit, help building standards for a program, and more.