Cutting tool manufacturers are always looking for ways to give their customers an edge — both figuratively and literally.

Demand for more effective turning processes is growing again in one of the most cyclical of industries — the resurgent oil and gas industry. Meanwhile, high-precision manufacturers in aerospace, automotive, and other manufacturing industries are on the lookout for more efficient turning processes.

Cutting tool manufacturers regularly test the waters with new product categories and, in some cases, new and innovative processes.

The one common denominator is that suppliers are not bashful about making eye-popping claims about possible machining improvements.

The problem is that manufacturers in shops of all sizes might be a bit slow to adopt the new tools. It’s in their nature. That said, here are several current approaches to improving turning processes.

Aiming for Oil and Gas

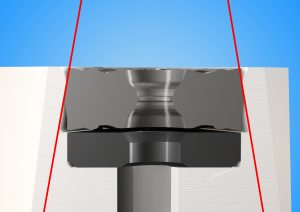

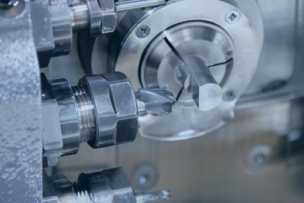

When Iscar (Arlington, TX) developed its Dove-IQ Turn product category some five years ago, the oil and gas industry was about to enter one of its cyclic downturns. “Today, that isn’t the case as the oil and gas industry is coming back strong,” said Randy Hudgins, Iscar national product manager for turning and threading. “Today there is demand in the oil and gas segment for large depths of cut (DOC) and high feed rates. Dove-IQ Turn is able to deliver high DOC of 4–12 mm and high feed rates of 0.4–1.0 mm/rev,” said Hudgins. The 1″ (25.4-mm) IC inserts can even reach up to 15-mm DOC.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *