Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

Lightweight cutters and damped adaptors enhance stability and productivity in long-overhang applications

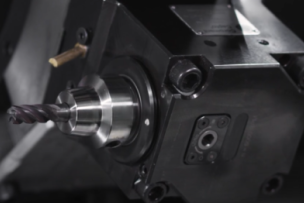

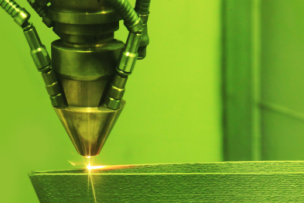

There are many well documented issues when it comes to the machining of workpieces with long-overhang tooling assemblies. Producing deep pockets and cavities, as well as machining alongside tall ribs, will inherently cause stability and rigidity problems. Unwanted effects such as vibration and deflection, which in turn lead to surface finish issues and dimensional errors, are the common outcome. However, extensive research and the development of new tool manufacturing processes has led to a solution that introduces higher levels of process security and brings about significant gains in productivity.

The benefits of damped adaptors have long been proven. A dampening device located within the tool holder absorbs vibration to promote process security and efficient cutting. However, a known limiting factor of damped tool holders is the weight of the cutting tools they accommodate. A conventional indexable-insert milling cutter in, say 50 mm diameter, might easily weigh over 300 g (10.6 oz). Such a mass makes it challenging for the damped adaptor to perform in the intended way, especially in extended-reach applications.

Complex component milling in, for example, Aerospace and Oil and Gas applications, can easily be compromised by excessive vibration and chatter. Machining a deep cavity requires a long overhang, a factor that is unavoidable. However, the vibration that results is compounded by using a conventional heavy tool, typically manufactured from some form of steel alloy. Unfortunately, excessive tool vibration and chatter will lead to

security risks, component quality issues, excessive noise levels, poor tool life and even scrapped components. To ensure the workpiece achieves both geometric and surface finish tolerance, operators are often faced with little choice but to go slower, which is counterintuitive in terms of meeting production schedules and achieving the required profitability.

In a conventional sense, there are some design changes that can be adopted to help remedy the situation. For instance, the introduction of a shorter distance between the damper in the adaptor and the cutting edge will improve structural strength and process security. In certain long overhang applications it may therefore be possible to increase the depth of cut and, subsequently, material removal rate (MRR). Additionally, the use of purpose-designed insert grades and geometries will deliver a light cutting action and smooth cutting performance.

Talk to Us!

I'm looking for an insert end mill type cutter the is 1.032 dia. to cut a slot .062 deep in 1018 CRS. I have one of your insert holders that the body diameter is 0.950 OD. I was wondering if there is an insert that would allow me the extend the cutting diameter to 1.032 dia or do you have an insert holder that would give me that diameter.

25Leave a reply

Your email address will not be published. Required fields are marked *