Focusing on the Workforce First: The Path Toward Transformation, Resilience and Productivity

Even as manufacturing heads for an anticipated strong recovery, it’s time to re-think how to put our people first.

Even as manufacturing heads for an anticipated strong recovery, it’s time to re-think how to put our people first.

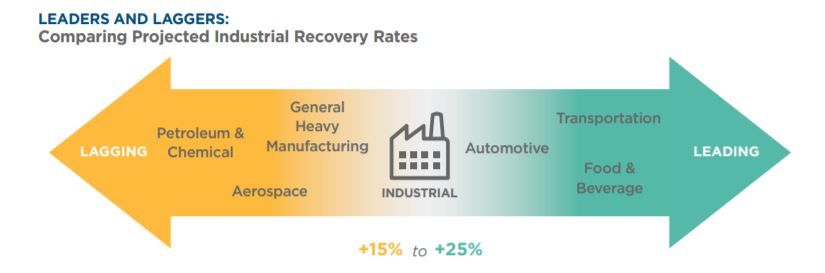

From long-term shutdowns, to production slowdowns, to a now unprecedented surge in demand and growth within e-commerce and warehousing, the pandemic has had a range of impacts on U.S. manufacturing. Research indicates these impacts are adding to existing labor challenges, which has created an even greater need for improved operational efficiency. In this unpredictable market, it’s never been more apparent the industry is dependent on physical labor. So focusing on and incentivizing the workforce can lead the charge in effective transformation. Even as manufacturing heads for an anticipated strong recovery, it’s time to re-think how to put our people first.

Manufacturers are tasked with balancing the need to invest in greater supply chain flexibility, but also recover financial losses resulting from mandatory shutdowns and lost productivity. In this environment, the ability to ramp up and keep up is dependent on a present and productive workforce.

To sustain efficient operations, companies will likely identify ways to enable employees to do more with less by investing in technology or innovation to simplify tasks. For those investing in greater supply chain flexibility through enabling technology or even localized production, it means having to spend wisely. Those budget constraints are guiding facilities toward products that can help reduce overall costs by controlling how much product gets used and wasted, and examining how much is spent directly and indirectly compared to other industry solutions.

Labor challenges have only gotten worse. Increased absenteeism, scheduling challenges due to newly fluctuating parenting duties and fear of an unsafe work environment have added pressure on employers to retain talent and keep productivity and morale high.

It’s never been more apparent that manufacturing is dependent on physical labor. As we recover, it’s time to rethink how to put our people first. To accommodate employee scheduling challenges, more shifts and flexibility will be needed, creating more “round- the-clock” operations. This also means new and increased maintenance programs to keep up with increased up-time, as well as meet the demands of heightened expectations around hygiene. Highly efficient, low-maintenance, hygiene-forward solutions that can ease both anxious employees and untrained maintenance staff will be key.

Massive surges in e-commerce resulted in new demands for warehousing, increasing competition for labor in a market already struggling to retain talent.

Whether seeking or trying to retain both production workers or highly trained engineers, companies will offer competitive compensation, a positive work culture, and attractive amenities. Facilities will likely maintain a strong focus on hygiene as part of safety protocols in order to demonstrate a safe and healthy workplace while offering a pleasant workplace environment.

Your business is adapting to survive. Consumer concerns are shifting. Now’s the time to use the same ingenuity you’ve applied all year to assess your operation: Identify productivity gaps. Re-evaluate hygiene and safety. Explore the benefits of automation. And re-examine the customer experience. Here are some ideas to help you visualize success long term:

Controlled-dispensing restroom collections with hygiene-forward towel, toilet paper, soap, sanitizer and air freshener dispensers can help you reduce overall costs by helping to reduce waste

High-capacity, closed-system napkin and cutlery dispensers feature one-at-a-time dispensing, which can help you reduce costs by reducing usage and waste

Substitute brown paper towels for white for additional savings

Touchless restroom dispensers and cutlery and napkin dispensers feature a high-capacity design that helps reduce maintenance and the need to refill

Disposable cleaning towels and Surface System sanitizing can help boost labor efficiency with one-at-a-time dispensing. Plus, employees will take notice of the portable Surface System dispenser in action.

Touchless, coordinated restroom systems with paper towel, toilet paper, soap, sanitizer and air freshener dispensers help show employees you care about providing a pleasant environment

Disposable plates, cups, napkins and cutlery can be more hygienic than permanent-ware dishes and help minimize personal contact, which protects employees from cross-contamination risk

Disposable, one-at-a-time cleaning towels and wipes help ensure employees get a clean, safe towel or wipe every time

Closed-system sanitizing (vs. open-bucket method) can help ensure sanitizer levels are maintained significantly longer, so you can help ensure a next-level-clean environment

Previously Featured on Georgia-Pacific's News and Knowledge site.

Go to MSCDirect.com for summer maintenance solutions to keep your employees healthier.

GP PRO manufactures and sells well-known brands like Brawny Professional®, enMotion®, Compact®, Angel Soft Professional Series® and foodservice brands including Dixie®, SmartStock® and PerfecTouch®. A division of Georgia-Pacific, GP PRO designs products to meet the specific rest room, foodservice and break room needs for a wide range of industrial and manufacturing facilities but also for commercial facilities in office building, healthcare, food service, lodging, retail and education sectors.

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)