Standards that guide FR clothing are based around performance at 50%, as that is when survival rates begin to drastically drop. The most recognized test method for establishing burn rates on garments utilizes standard ASTM F1930, performed on a manikin test subject. The method tests a garment at three seconds with a pass/fail rate of 50% total body burn.

Here are some of the key takeaways from the American Burn Institute's 2017 National Burn Repository:

- For survivors, the average length of the hospital stay was slightly greater than 1 day per % total body surface area (TBSA) burned.

- For those who died, the total hospital stay was typically between 2-3 weeks in patients with %TBSA < 80%.

- Generally, 87% of patients were discharged home and 3% were transferred to rehabilitation facilities.

- Overall, the charges for patients who died were over three times greater than those who survived; however, this was greatly affected by a large number of patients with burns < 10% TBSA. For burns >10% TBSA, total charges for surviving patients averaged $269,523 and charges for non-survivors averaged $361,342.

What MCR Safety hopes you take away from the information above is that each percentage point jump in TBSA% results in greater recovery time for workers and a greater overall cost to the company. In addition to burn injuries, the repository notes that death rates from burn injuries increase with a worker’s age, burn size, and the presence of heat inhalation injury. The 2012 National Burn Repository provides data that proves inhalation injury increases the mortality rate by 16 times. In another journal source from the NCBI, data shows that the overall mortality rate among patients with inhalation injury was 41.5%, compared with 7.2% among patients without inhalation injury. These figures indicate that inhalation injury is a leading cause of death when workers are exposed to fires. Approximately 80% of fire-related deaths are due to the inhalation of toxic products, especially carbon monoxide and hydrogen cyanide gases.

This is where MCR Safety enters the picture.

Burn Rates and Summit Breeze® Technology

Is it possible to achieve FR compliance and only meet the minimum standard? The answer is absolutely and unfortunately: Yes. NFPA 2112 does not differentiate performance from 0% body burn to 50% body burn. No such labeling is required. Keeping the body burn rate lower than 50% is the minimum requirement to meet the guidelines set by NFPA 2112, which means that many times that number becomes the focal point for garment manufacturers.

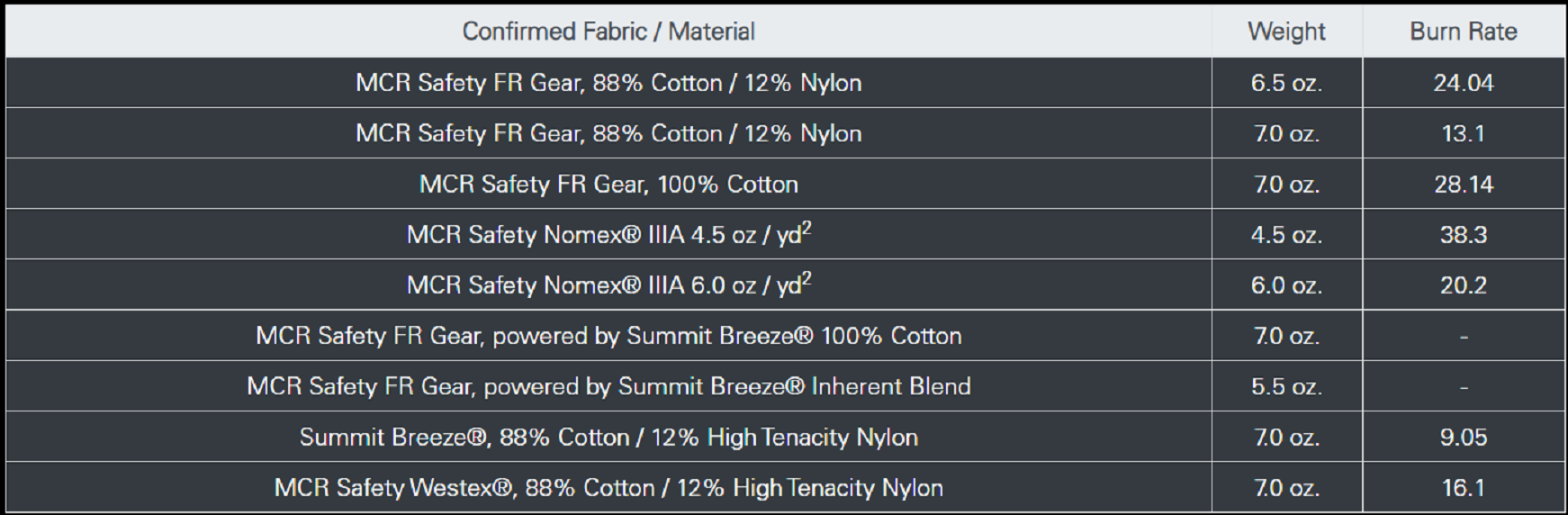

However, not all NFPA 2112 products perform to the same level. Some companies may only strive to offer products that meet minimum specifications. At MCR Safety, we’ve never done business that way. Whether it’s a cut-resistant glove achieving A9 performance or FRC achieving low burn rates, we go above and beyond the minimum specifications. In the table below, MCR Safety highlights their Summit Breeze® technology’s burn rate performance compared to other material utilized in FR garments.

When you’re dealing with flash fires that often last only a few seconds, the initial protection offered goes a long way. With the addition of Summit Breeze® technology, workers have the best flash fire performance offered.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *