Disposable Gloves: 5 Tech Innovations to Get Your Hands On

Not all disposable gloves are created equal. Here are five innovations that are transforming the comfort, performance and protection of disposable single-use gloves.

Not all disposable gloves are created equal. Here are five innovations that are transforming the comfort, performance and protection of disposable single-use gloves.

Disposable gloves have a critical role in metalworking and manufacturing. Workers wear them to protect against abrasions, chemical splashes, repetitive strain injuries and more. Because gloves are used so frequently and often look similar, they might appear to be interchangeable. They aren’t.

“It would be very easy to look at disposable gloves as a commodity,” says Robyn Urbanovich, a senior specialist of single-use products at Ansell. “But not all disposable gloves are built equal. There are different technologies that can be added to a disposable glove that make it stand out.”

Ansell has a team of experts who spend time with workers on the job to develop a greater understanding of their challenges, Urbanovich explains. This research, part of the company’s Worker Experience Innovation program, has led to the creation of more than a dozen proprietary technologies in personal protective equipment (PPE) that are designed to keep people safe and improve how they work.

Here are five technologies and innovations that are transforming the comfort, performance and protection of disposable single-use gloves.

When safety gloves—like any PPE—are uncomfortable or get in the way of performing a task, a worker may simply remove them, increasing the risk for musculoskeletal disorders and other injuries. To address this concern, Ansell has extensively studied hand ergonomics and focused on solutions that consider fit, grip, construction, comfort, and application-specific issues such as vibrating machinery and wet conditions.

Now, workers don’t have to choose between comfort and protection.

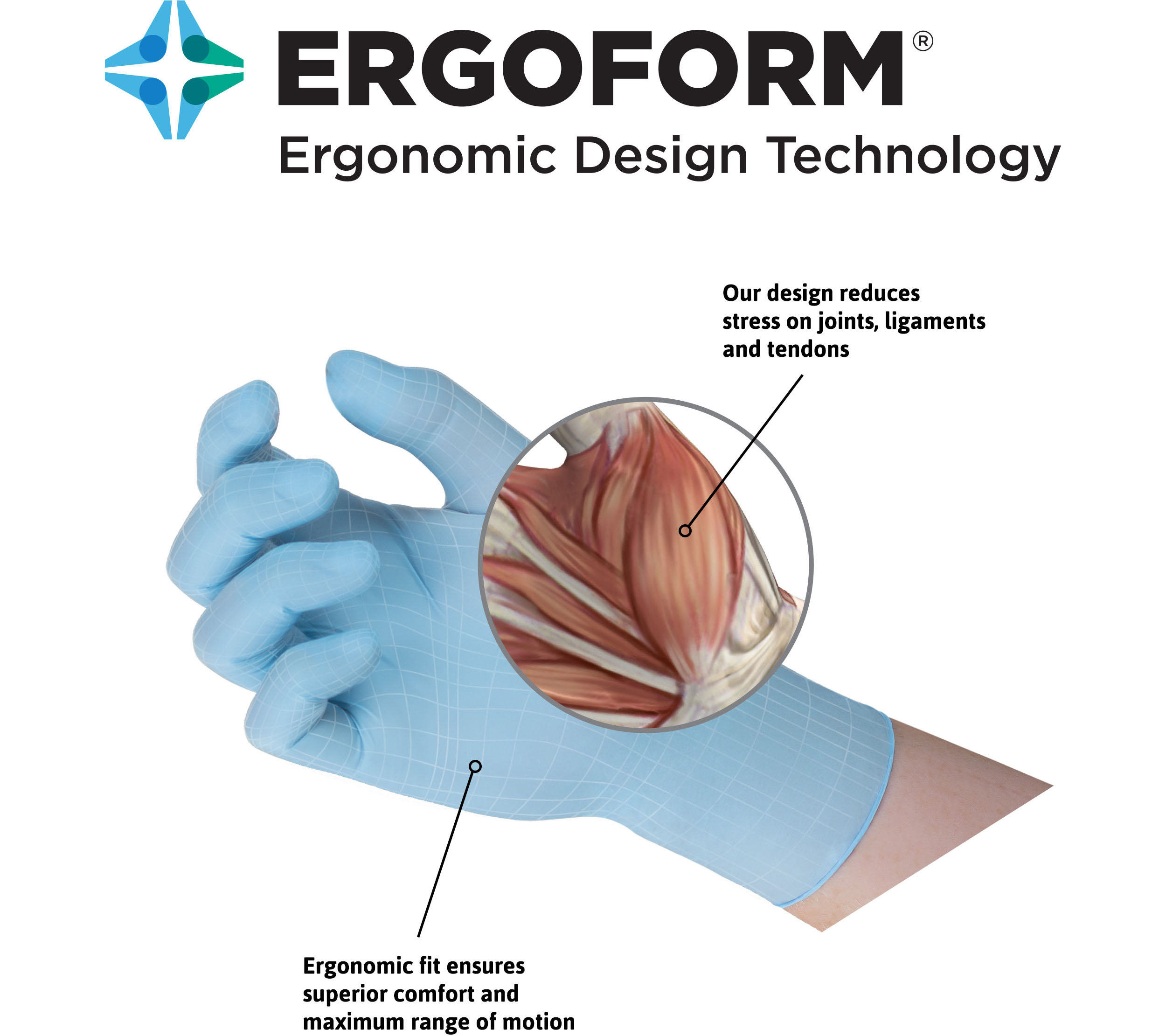

Products with Ergoform™ technology feature an ergonomic fit to ensure superior comfort and maximum range of motion while reducing stress on joints, ligaments and tendons.

“Gloves with our Ergoform technology are scientifically proven—through quantitative and qualitative measures—to reduce muscle effort and strain,” says Kevin Brennan, associate director for single-use products at Ansell.

“The gloves are made of elastic materials. They’re not stiff,” Brennan adds. “With Ergoform, workers are going to want to know that they can move their hands around a lot easier, and there’s less force needed. If you’re on an assembly line and you’re doing the same task over and over again, there is less risk that you would have an ergonomic injury like carpal tunnel.”

Read more: Know Your Glove Size Instantly

With disposable gloves, people are aware of latex allergies, but there is less familiarity with allergies to nitrile products, Brennan says. More accurately, the allergy is to accelerators used in the formulation process.

“Although these kinds of allergic reactions aren’t as common as latex, if there is a plant manager who knows he has one or two people with this allergic reaction, he just wants to get something that’s accelerator-free for everybody,” he says. “He doesn’t want to have to worry about special gloves for one person.”

Ansell’s most popular thin glove, Microflex® XCEED® XC-310, is made without accelerators such as thiurams and carbamate, which helps avoid the contact dermatitis that some people can experience with nitrile gloves.

“When the glove goes from a liquid to a solid, it goes through a vulcanization [or curing] stage, and chemical accelerators help speed up that process,” Brennan says. “We have a cross-linking technology with the polymer bonding, and we’re able to do this without those accelerators.”

XCEED XC-310 gloves also have Ergoform technology, making them a preferred product in a variety of applications where comfort is key, including cleaning, disinfection and sanitization; analytical testing and measurement; sample taking and processing; food processing; and light assembly tasks.

Microflex Lifestar EC™ LSE-104, a dual-layered medical-grade glove, is also manufactured without accelerators. Plus, it has a nonfoaming formulation—which is great for wet grip, Brennan says—and a nonstick formulation to reduce interference with tapes and adhesives.

Read more: Factors in Glove Selection: Disposable Protection

Anyone working with their hands around oils, solvents and other hazardous chemicals can appreciate the value of splash protection in their gloves. Ansell’s TNT™ chemical splash resistance technology is designed to provide durable protection with a soft, comfortable feel.

“With better chemical splash protection, workers change their gloves less often, so there is less waste and less cost associated,” Urbanovich says. “The glove is more durable, and it can withstand more as they’re doing the job.”

Having TNT chemical splash protection suits Microflex Onyx™ N64 gloves, which are used widely in the automotive, machinery and equipment, and metal fabrication industries.

“The black color can mask stains in some instances and provide contrast to materials such as powders in other situations,” Brennan says. “It’s silicone-free, which is great for painting and finishing applications.”

TNT is a desirable feature in TouchNTuff® 92-600, Ansell’s most popular glove worldwide. With an extended size range to include XS and XXL, the 92-600 is used in automotive, chemical handling, food processing, machining, maintenance and production.

Workers in certain environments need extra chemical protection, and previously, they couldn’t have it in a disposable glove. They were forced to settle for bulky traditional chemical gloves that limit dexterity.

When Ansell debuts TouchNTuff 93-800 with Microchem™ later this year, all that will change.

“This will be our first disposable product with Microchem technology,” Urbanovich says. “It will have three layers: the outermost latex, then neoprene, and the innermost, the donning polymer, will be nitrile.”

She adds that the disposable gloves will have 15 minutes of resistance to acetone and ketones, which is a first in the market.

“Typically, customers are using gloves that only have about three minutes of protection when working with acetone, so having 15 minutes of protection will be a really big game-changer for them,” she says.

Many metalworking and manufacturing companies with an eye on sustainability believe the greenest solution for disposable gloves is biodegradability of single-use products.

Ansell believes the most significant contributor to disposable glove sustainability is lowering the environmental impact of the manufacturing process, not necessarily the carbon dioxide (CO2) released when a glove degrades in a landfill.

Read more: Ansell Bangkok at a Glance: Disposable Gloves Made with Green Energy

To that end, Ansell’s manufacturing facility in Bangkok follows a number of green practices: It generates thermal energy with biomass, using wood chips to create heat; it aims to send zero waste to landfills and is certified by Intertek for achieving at least 99 percent waste diversion; it uses reverse osmosis treatment for reusing water at the plant; and it makes packaging with at least 70 percent recycled paperboard.

“Only 1 percent of CO2 emissions come from the end of life of the glove, that landfill process,” Brennan says. “Obviously there is more that impacts the environment besides CO2 emissions, but for CO2 emissions alone, the raw material and manufacturing process is the biggest impact.”

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)