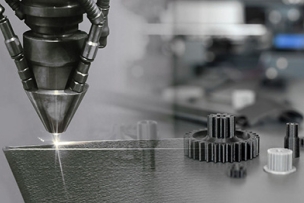

COVID-19 has unexpectedly demonstrated the potential of 3D printing in a very public way. Manufacturers and healthcare professionals have come together to create and deliver 3D printed lifesaving equipment such as ventilators, nasal swabs, and face shields to combat the deadly virus.

The use of medical 3D printing technology has already been an important part of the healthcare industry. From anatomical models to surgical instruments to precision prosthetics, additive manufacturing/3D printing is helping doctors and institutions provide quality care for patients at a reasonable cost. And there is much public health innovation on the horizon with bioprinting and tissue fabrication.

Other industries such as aerospace and automotive are also increasing their reliance on 3D printing technology and finding new applications for additive manufacturing.

Additive Manufacturing Market Size

Let’s take a look at the market size. While this projection was made pre-coronavirus, according to Wohlers Associates, Inc., additive manufacturing will be a $16 billion industry in 2020. Impressively, that is expected to grow to $40.8 billion by 2024.

Urgent Need for 3D Printing Training

A big challenge for manufacturers facing the rise of new 3D printing technology is training. The push to develop workers to become proficient in skills connected to Industry 4.0, like additive manufacturing, comes at a time when manufacturers are already challenged by worker pipeline issues related to retiring baby boomers, increased onshoring and more.

Job roles are changing, and manufacturers must adapt to keep up and, ultimately, thrive.

Competency-based 3D Printing Training

Competency-based training is essential to build skills proficiency. With SME’s decades at the helm of additive manufacturing and Tooling U-SME’s expertise in instructional design, they offer high-quality training in design, safety, production, or any other additive topic.

Two recent workforce and education grants from the Department of Defense have allowed them to support the skills development of America’s workforce in the defense sector, and some of that work covers additive manufacturing.

They are happy to make the resources—including those related to additive manufacturing—available outside of the defense sector to thousands of manufacturing companies and hundreds of educational institutions that they support nationwide.

3D Printing Training Resources

Here are some of their resources that can help you as you ramp up your 3D printing/additive manufacturing workforce:

- Additive Manufacturing Online Classes. These courses include beginner and intermediate level competency-based courses covering topics such as Intro to Additive Manufacturing, Additive Manufacturing Safety, Design for Additive Manufacturing, Integrating Additive Manufacturing with Traditional Manufacturing and more. They are working with industry and academia to incorporate these courses into effective blended-learning programs.

- Instructor-Led Training. They will connect you with instructors who are knowledgeable, experienced, and passionate about teaching others—and who can work with you to create custom additive manufacturing training solutions.

- The Additive Manufacturing Fundamentals Certification and Additive Manufacturing Technician Certification are stackable, creating a flexible, modular pathway for mastering the principles and processes of additive manufacturing. The certifications align to the Additive Manufacturing Body of Knowledge compiled by Tooling U-SME, America Makes, the Milwaukee School of Engineering (MSOE), the National Coalition of Advanced Technology Centers (NCATC), and Technician Education in Additive Manufacturing & Materials (TEAMM), with input from more than 500 additive manufacturing professionals.

- Turnkey Training delivers immediate instruction in high-demand areas such as the Additive 3D Technician job role. When combined with on-the-job training (OJT), Turnkey Training quickly creates a learning road map and career path for new hires and tenured employees.

- Learning Services. Tooling U-SME's team works onsite with their customers to develop effective training programs. They are seeing an increased demand for 3D printing training which can be customized to meet your business goals.

Well-trained manufacturing workers regularly deliver positive operational metrics (i.e., productivity, safety, quality) while also innovating and problem solving on behalf of their employer.

The crisis with COVID-19 has shown just how critical “pivoting” is in order to respond quickly and effectively to unexpected events.

Training your employees to keep up with the latest 3D printing technologies and additive manufacturing processes—and other Industry 4.0 advancements—can help ensure that they are already in an “innovation” mindset, always thinking about how to improve and advance to meet your business needs.

Previously Featured on Tooling U-SME's blog.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *