The measuring station TESA μ-HITE accelerates the control process of components manufactured by Dubuis for the electrical, railway, health and aeronautic industries.

The Dubuis company capitalizes great knowledge in the design and manufacture of a wide range of portable products.

The fast and reliable control of its components is one of the fundamental points for an ever increasing productivity and it avoids any waste of time and resources.

Therefore, Dubuis chose the TESA μ-HITE measuring station.

With an application range of 100 mm, suitable for laboratories as well as workshops, the TESA μ-HITE is particularly adapted for the measurement of small parts.

Thanks to 1 μm precision and its compact shape, it can easily be integrated into a production area to allow accurate measurements in the long term on many types of materials with a low and adjustable measuring force.

Established for more than 60 years in Blois in Centre-Val de Loire (France), in 2006 Dubuis has been part of the Stanley group and since 2010 part of the Stanley Black and Decker group and today employs 92 people in Research & Development, Manufacturing, Assembly, After-Sales Service and Sales.

Dubuis sells its products throughout the world via distributors specialized in Building, Public Works and Railways as well as customers such as RATP (Autonomous Operator of Parisian Transports), EDF (Electricity of France), ALSTOM and BOMBARDIER.

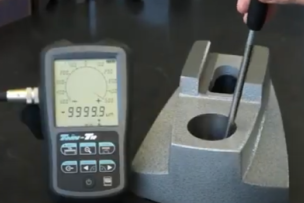

For one of its products, Dubuis uses the μ-HITE to determine whether the internal cone angle of a sleeve meets the expected specifications. To do this, they compare the height difference between the upper surface of the part and the height of a reference ball measured by a flat probe.

“We have 2 TESA μ-HITE directly installed on turning machines that are used in three shifts. They measure about 100 pieces each day,” explains Laurent Hernandez, Industrial Development Manager.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *