Precision Tool Technologies Inc. is a manufacturer and distributor of high quality products and services for wholesale optical laboratories and retail optical industries. Their first success came in the precision machining of polishing tools and mold inserts for the optical industry, where accuracy of ± 0.0001” and surface finishes of 4 Ra are required. For successful operations, this level of excellence must be repeatable on a daily (and nightly) basis. During the course of perfecting their techniques, Precision Tool became the “go to” company for solving difficult machining problems for a variety of industries. HAIMER has been a key partner in helping them maintain this competitive edge.

Digital Dynamics

HAIMER entered the picture when Precision Tool began running lights outs (what the company calls a “virtual shift”) due to an increasing demand for their services. This posed a challenge since their equipment consistently runs at speeds up to 40,000 rpm. “We didn’t want to take the chance of buying equipment for 7-figures and then start blowing out spindles,” said Jim Goerges, the company’s President. “The solution presented itself when I read an article written by HAIMER.”

The article, “Unbalanced Perceptions”, detailed the importance of toolmakers and machinists working together to achieve better results with harmonics and balance. According to Jim, “We call something ‘art’ when we don’t understand what we are doing. In this article, HAIMER turned the ‘art’ into science…and that’s what makes it repeatable.” The article is now mandatory reading for all Precision Tool engineers.

With the article as a guide, Jim and his team set about building a better process that would enhance their digital platform, increase productivity and improve product quality. According to Jim, there were three vital elements required to move Precision Tool ahead of the pack.

One: Change Management

We created a positive mindset about the program and made sure everyone understood the vision and became totally committed to it,” he said. “If you don't have that buy-in, nothing else matters. People needed to get to a place where change was always a welcome component to the operation as a whole.”

Two: Quality Tooling and Equipment

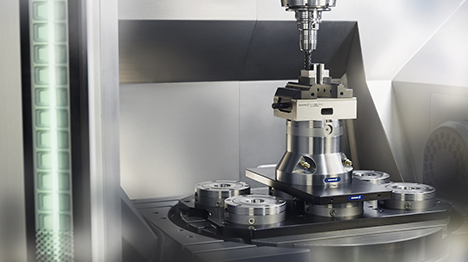

For Precision Tool, this meant HAIMER HSK tooling and shrink fit systems. (No collets, side locks or Weldon flats.) Shrink fit provides them with repeatability and helps reduce tool stick out. They worked with local HAIMER manufacturer’s representative Andrew Skoog to put together the right package.

Three: Balanced Assemblies

To say that Precision Tool is a fan of balancing is an understatement. According to Technical Advisor Gary Goerges, “HAIMER raised our awareness of how good things can be if you balance tool assemblies. In our situation, surface finishes on our equipment are now pretty spectacular. With the HAIMER Tool Dynamic, we can get very particular on how close we want to balance something.”

Jim agrees. “Much of our customer base had the same problems (accuracy, blown spindles and poor surface finishes). Because of the HAIMER balancing machine, we now have the means to provide them with a solution. The word has gotten around that we can handle the hard jobs other shops can't."

Doing the Impossible Part I

One of Precision Tool’s customers had a part problem that had their in-house engineers stumped. The part was a conical funnel with holes used to fill chemicals or test equipment for genetic decoding. This complex aluminum part has internal finishes with conical shapes, 40-50-60 times stick out length and must have a 4-6 Ra finish after coating (which doubles the surface roughness). This combination of requirements made it impossible for other shops to do the job.

The engineering staff at Precision Tool’s customer admitted they couldn’t make the part. As a result, the company was having a hard time making delivery times, so they decided to give Precision Tool a shot.

The HAIMER balancer made all the difference. Precision Tool manufactured the part and sent it back to their customer – and they were floored. “Nobody could make the part to the finished specs that they wanted,” remarked Jim. “We did it and a big part of that was how exact we were able to get in terms of balancing special machine tooling to achieve the surface finish on the internal features. In fact, we would not have been able to perfect the harmonics without the HAIMER balancer.”

Jim credits the balancer for giving Precision Tool a competitive advantage on many different levels. “It’s often the difference between saying ‘yes’ or ‘no’ to a job,” he said.

Doing the Impossible Part II

Another example of how the partnership of Precision Tool and HAIMER managed to achieve what no one else could was in the manufacture of an aspirator attachment for a seeding machine. When the part spins in the machine, it gets up to 12,000 rpm. If it is out of balance, it shakes the entire seeding machine – making all the components vibrate and causing premature retirement of the machine due to excess wear.

No one could make the part work to spec, but Precision Tool could. While their attachment carried a premium price compared to other vendors, the customer saw the value that the superior part would bring to the overall quality of their seeding machine. This was all due to Precision Tool’s ability to utilize the HAIMER balancing machine on not just tool holder assemblies, but on physical parts as well. The TD 2009 machine was able to identify unbalance and accurately designate the exact position where weight correction was needed.

Becoming Better and Better

Precision Tool’s next investment to complement the balance and shrink fit machine will be a HAIMER automatic presetter. “It will give us a better, faster, more accurate way of bringing a complete tooling solution to the machine instead of stopping the machine during the run,” Jim said. “Adding presetting to shrink fit and balance will allow us to create a total throughput solution for all of our operations.”

Previously Featured on HAIMER's News & Media.