Are you aware of the many advantages of 3D printing technology? Follow along as Makerbot breaks down the top 10 here.

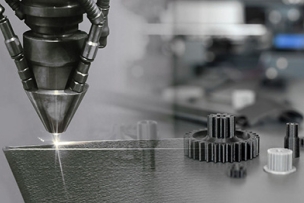

There are three main methods used for product development, that is, taking a design from idea to a physical, three-dimensional prototype of the product.

Subtractive manufacturing is a product development process that continuously cuts away material from a solid block, such as metal. This can be done manually or using CNC (Computer Numeric Controlled) machinery.

Injection molding is a manufacturing process used for producing products in large volumes. As the name suggests, parts are produced by injecting heated material into a mold.

So, what is 3D printing? Additive manufacturing, aka 3D printing, is the process of producing three-dimensional objects from a computer file, where the part is built by adding material layer by layer.

Today, more companies in a variety of industries are embracing the 3D printing process as it presents many significant advantages over the more traditional manufacturing methods of subtractive manufacturing and injection molding.

1. SPEED

One of the biggest advantages of 3D printing technology is Rapid Prototyping. Rapid Prototyping is the ability to design, manufacture, and test a customized part in as little time as possible. Also, if needed, the design can be modified without adversely affecting the speed of the manufacturing process.

Before the 3D printing industry came to flourish, a prototype would take weeks to manufacture. Every time a change was made, another few weeks of time were added to the process. With shipping times figured in, fully developing a product from start to finish could easily take a year.

With 3D printing techniques, a business can design a part, manufacture it in-house on a professional 3D printer, and test it, all within a few days (and sometimes even less).

For small businesses or even individuals, this difference is significant. The freedom and creativity enabled by 3D printing means that almost anything can be created without the need for warehouses full of expensive machinery. There are no long lead times typically associated with having to outsource complex manufacturing projects. It means freedom from the constraints of minimum orders, that parts and products can be created and customized with ease.

For small production runs and prototyping, 3D printing is the best option as far as speed is concerned.

2. COST

For small production runs and applications, 3D printing is the most cost-effective manufacturing process. Traditional prototyping methods like CNC machining and injection molding require a large number of expensive machines plus they have much higher labor costs as they require experienced machine operators and technicians to run them.

This contrasts with the 3D printing process, where only one or two machines and fewer operators are needed (depending on the system) to manufacture a part. There is far less waste material because the part is built from the ground up, not carved out of a solid block as it is in subtractive manufacturing and usually does not require additional tooling.

3. FLEXIBILITY

Another big advantage of 3D printing is that any given printer can create almost anything that fits within its build volume.

With traditional manufacturing processes, each new part or change in part design, requires a new tool, mold, die, or jig to be manufactured to create the new part.

In 3D printing, the design is fed into slicer software, needed supports added, and then printed with little or no change at all in the physical machinery or equipment.

3D printing allows the creation and manufacture of geometries impossible for traditional methods to produce, either as a single part, or at all. Such geometries include hollow cavities within solid parts and parts within parts.

3D printing, in contrast to traditional methods, allows the inclusion of multiple materials into a single object, enabling an array of colors, textures, and mechanical properties to be mixed and matched.

3D printing allows any user, even those with limited CAD experience, to edit designs however they like, creating unique, customized new parts. This also means any given design can be manufactured in a wide range of different materials.

4. COMPETITIVE ADVANTAGE

Because of the speed and lower costs of 3D printing, product life cycles are reduced. Businesses can improve and enhance a product, allowing them to deliver better products in a shorter amount of time.

3D printing allows the physical demonstration of a new product to customers and investors instead of leaving it to their imaginations, therefore reducing the risk of information being misunderstood or lost during communication.

It also allows for cost-effective market testing, obtaining feedback from potential customers and investors on a tangible product, without the risk of large upfront expenditures for prototyping.

5. TANGIBLE DESIGN AND PRODUCT TESTING

As previously described in competitive advantages, seeing a product on a screen cannot compare with actually touching and feeling a prototype. A physical prototype can be tested and if flaws are found, the CAD file can be modified and a new version printed out by the next day.

6. QUALITY

Traditional manufacturing methods can result in poor designs and, therefore, poor quality prototypes. Imagine baking a cake, where all the ingredients are combined and mixed together, then placed in the oven to bake. If it happens the elements were not mixed well, the cake would have problems like air bubbles or fail to bake thoroughly. The same can occur with subtractive or injection methods; quality is not always assured.

The nature of 3D printing allows the step-by-step assembly of the part or product, which guarantees enhancement of the design and better quality parts/products.

7. CONSISTENCY

As mentioned above relative to quality, traditional manufacturing processes can result in a percentage of a batch of parts being defective or inconsistent in quality compared to the rest of the parts.

In 3D printing, the parts are printed in succession. Each successive individual part can be monitored, allowing errors to be caught in real time, reducing the overall number of failed parts and wasted materials while increasing consistent quality of the parts produced.

8. RISK REDUCTION

Because of the previously mentioned advantages of quality and consistency, 3D printing allows a business to mitigate its risks in manufacturing. 3D printing technology allows product designers to verify product prototypes before starting out on substantial manufacturing investments that can be potentially disastrous.

9. ACCESSIBILITY

3D printing systems are much more accessible and can be used by a much wider range of people than traditional manufacturing setups. In comparison to the enormous expense involved with setting up traditional manufacturing systems, a 3D printing setup costs much less. Also, 3D printing is almost completely automated, requiring little to no additional personnel to run, supervise, and maintain the machine, making it much more accessible than other manufacturing systems by a good margin.

10. SUSTAINABILITY

With 3D printing, fewer parts need outsourcing for manufacturing. This equals less environmental impact because fewer things are being shipped across the globe and there is no need to operate and maintain an energy-consuming factory.

3D printing creates a lot less waste material for a single part plus materials used in 3D printing generally are recyclable.

The main advantages of 3D printing are realized in its speed, flexibility, and cost benefits. For small production runs, prototyping, small business, and educational use, 3D printing is vastly superior to other industrial methods.

Previously Featured on Makerbot's 3D Printing Resources page.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *