If your organization is on the fence, or has previously evaluated automating your weld grinding processes and determined it was not feasible at the time, now is the time to reconsider. The challenge of finding and retaining labor for such a manual task was already a compelling reason to automate, and now doing so within the context of COVID-19 safety restrictions and increasing labor costs has only exacerbated the issue. At the same time, the opportunity to capitalize on the benefits of automating your weld grinding processes is amplified by the presence of new industry partners, technology advancements, and commercialized offerings, like 3M and Lincoln Electric’s new pre-configured, one-of-a-kind grinding system.

Of course, automated weld grinding may not be a top priority for every organization yet as every operation is unique and processes must be adapted to fully realize the benefit. However, there are some common characteristics that can help you determine if automating this labor-intensive process might be a big step in the right direction for your business. Here are five of them to consider:

- You have already automated some of your processes, like welding.

Among the more obvious reasons you should be considering automation for weld grinding is if your organization has already implemented automation somewhere in your process. Any degree of familiarity with the integration of robotics gives you several unique advantages, including that you are more likely to:

- Know how to evaluate the ROI of automation for a process, allowing you to apply similar methods to prove the business case for automating a process as intensive as weld grinding

- Have a framework of protocols for how robotics are leveraged in your process. This could include safety and operating instructions

- Understand the inherent challenges of leveraging automation and how to overcome them

- Employ robot programmer(s) and understand the unique technical skills that this position requires

- Know how to capitalize on the ability to repurpose labor and shift your workforce into higher-skilled positions through training programs—meaning that you can redirect your labor costs towards more skilled tasks

These only scratch the surface. There are likely an untold number of other intangible advantages that come with “knowing the territory” of automation, from the dynamics of your specific workplace culture to how your company, brand and products are perceived in the market.

- You want to transform the daily grind for your manual welders pulling double duty.

Companies that have not yet automated their welding processes can still realize significant benefits from automated weld grinding, like keeping their highly skilled (and highly sought after) welders happy. It is a somewhat common practice for many metal fabrication shops to expect welders to also perform weld grinding. But while these two steps may be inextricably linked in terms of their importance to your process, the latter is a far less skilled and more labor-intensive task that likely provides lower job satisfaction. While some welders may appreciate the ability to ensure their craftsmanship is followed up by the same high level of quality and care that they put into their welding, they do not necessarily need or want to be the ones responsible for it.

Allowing welders to focus on their specific niche of welding could result in a higher level of job satisfaction, quality, and productivity as they are not needing to switch between multiple tasks with highly varied requirements, tools, and safety procedures. Furthermore, by eliminating one of the most ergonomically taxing and physically demanding tasks from their job requirements, you are demonstrating that you care for the safety and wellness of your employees. This incentivizes them to stay with your business, staving off the longstanding industry trend of high turnover and labor shortages in the welding industry. At the same time, when hiring new welders, you will not need to require applicants to serve the dual-role of both welder and grinder, making for a more alluring job opportunity.

Ultimately, by automating the grinding process, you can instill confidence among your welders that their work is valued and will be treated with the same consistent quality of grinding every time, and that they can count on robotic grinding to “finish strong” for them.

- You are looking to solidify your operational productivity.

No matter where your business resides on the automation spectrum, four key principles drive business decisions: time, costs, quality and safety. Any significant variances or unexpected fluctuations in any of these can make it virtually impossible for you to operate as profitably, efficiently and ethically as you could be. By introducing the predictability of automated weld grinding into your operation, you can advance your business on each of these fronts.

- Time: Like automated welding, automated weld grinding can help your cycle times reach a new level of speed that you can reliably count on from day to day. Robots can perform the same weld grinding tasks on the same timelines and operate around the clock for more uptime in your process. On top of that, their ability to apply higher forces allows them to achieve faster cut rates, reducing cycle times even further. Plus, in many cases robots can also utilize a larger, more premium 7" abrasive disc rather than the standard 4.5" disc commonly used in a manual process. These larger discs deliver even greater life and cut-rate than their smaller counterparts, which can mean faster grinding with fewer disc changeovers.

- Quality & Costs: Robots will consistently finish each part the same way every time, virtually eliminating the potential for error and thereby reducing scrap material. When programmed and optimized correctly—accounting for force control, speeds, feeds and the abrasive disc—a robot can process each part brought into the cell consistently without overgrinding or undercutting. It can even utilize the consumables more efficiently through optimizations that allow the entire abrasive to contact the substrate, increasing the contact surface area. The result? Even longer disc life and even fewer changeovers.

- Safety: While most operations have implemented best practices to help protect employee safety in their weld grinding processes—from providing protection against airborne dust contaminants, to noise hazards, to providing tools and consumable abrasives designed for ergonomics— it remains a physically demanding task that will likely always pose at least some level of risk to the operator. With the addition of the uncertainty surrounding the current COVID-19 crisis, the new challenge of providing adequate space for safe physical distancing between operators can also put a strain on the workforce capacity of your operation. Automating weld grinding and weld blending addresses each of these safety challenges, allowing you to optimize the use of physical space; solutions like 3M’s pre-configured automated grinding system come in a Lincoln Electric cell, so you know exactly how much space they require without introducing potential contact hazards with people on the floor.

- You have been waiting for the technology to “catch up.”

It is true that, until very recently, weld grinding had typically been too complex of a process for automation to address on a large scale or in a profitable manner, so it’s no surprise that many businesses have waited to explore implementing an automated solution. Fortunately, that is no longer the case, as recent advances in force control technology and abrasive optimization have resulted in a viable system solution for a greater variety of weld grinding and blending applications than ever before.

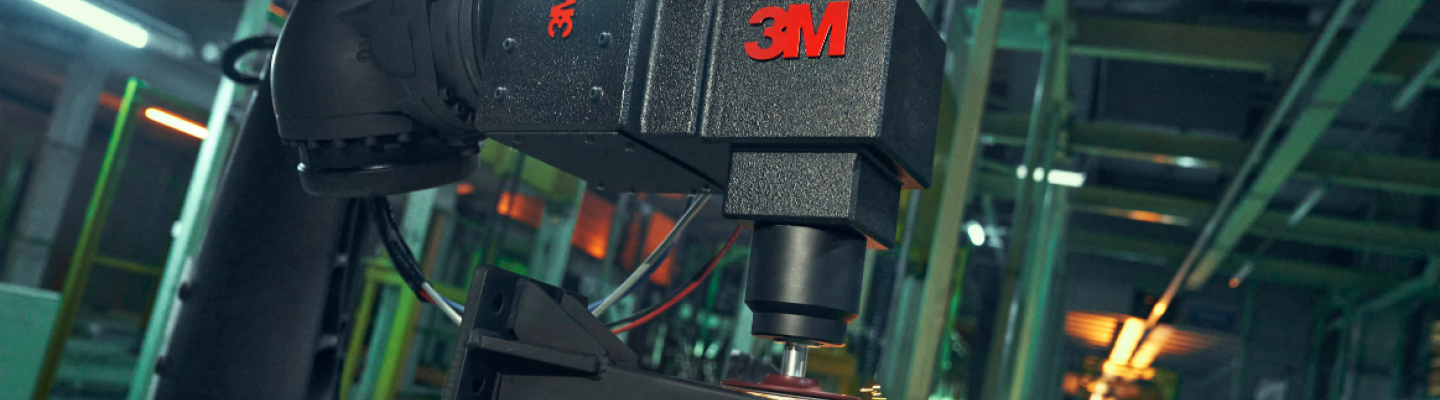

A pre-configured automated grinding system from 3M and our partners consists of some of the latest technologies working together to deliver precise, quality weld grinding:

- 3M™ Servo Rotary Tool

- 3M™ Cubitron™ II and Scotch-Brite™ Abrasive Discs

- KUKA KR 60 Robot

- 3M™ Active Compliant Force Tool

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *