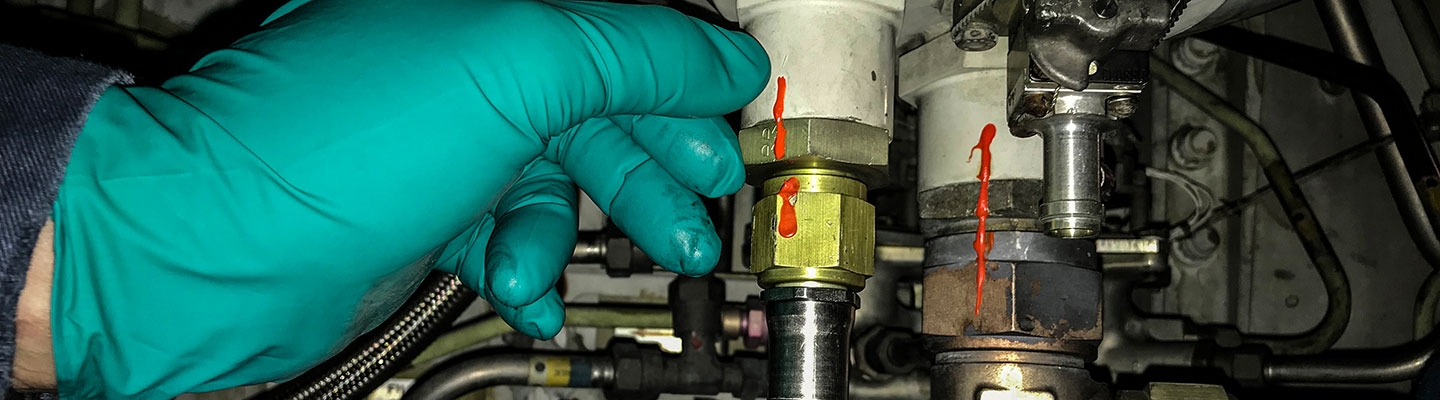

With DYKEM Cross Check torque pastes—which indicate the integrity of connections held together with nuts, bolts and other fasteners—ITW Pro Brands offers manufacturers a tool that enables both safer operation of industrial equipment and better quality control.

Manufacturers in aerospace, automotive and other industries rely on the 3D indicator, developed in 2007, to verify that products meet specifications before delivery, while customers use them to alert safety inspectors when connections are loosening.

“It’s a huge timesaver because rather than having to physically check torque at every connection, they can visually check if a bolt or fastener has lost integrity, whether because of tampering or vibration during use,” says Greg Coy, product manager for ITW Pro Brands' DYKEM line.

Detecting connection problems early, Coy explains, can prevent failure of joints critical to machinery from airplanes to tractor-trailer rigs and roller coasters.

Not only is that an important part of complying with the Occupational Safety and Health Administration’s general duty clause, which requires employers to ensure workplaces are free of known hazards, it avoids consequences ranging from the expensive—product recalls and fines—to the physically harmful or even deadly.

Meeting torque—or twisting force—specifications on fasteners “is one of the most important tasks when assembling and performing maintenance on heavy equipment,” Coy says.

Preventing Connection Deterioration

But even with correct specifications, once equipment is in use, “fasteners become subject to the stress of everyday operation such as vibration, heat, temperature fluctuations, and moisture,” he says. “Even the most precise application of torque cannot prevent some form of deterioration over time.”

While a variety of marking tools are available to flag problems, the type needed depends on several variables. A simple paint marker may be sufficient for some connections, while a three-dimensional paste is preferable for heavy equipment or high-risk environments.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *