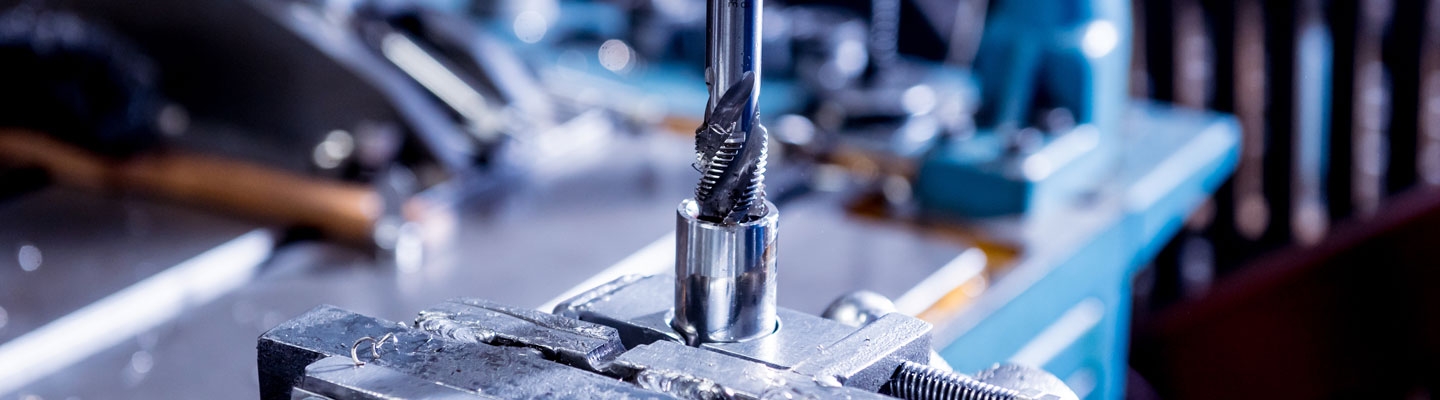

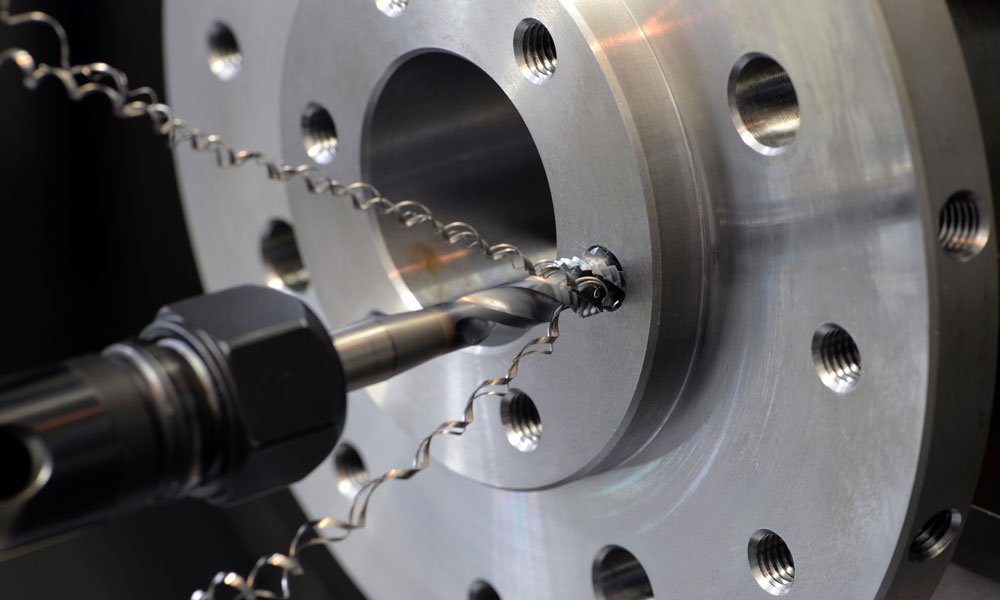

Many machinists regard thread milling as the preferred method of generating internal threads. Tapping, on the other hand, is significantly faster, is largely considered easier to set up and generally calls for less-expensive cutting tools.

When comparing one machining method with another, however, it’s always best to speak to experts who are familiar with both. Marlon Blandon, thread mills product manager for EMUGE Corp., and Kyle Matsumoto, product manager for OSG, spend their days thinking about threads and the best way to cut, form or mill them.

Here, Blandon and Matsumoto discuss the pros and cons of these two threading methods.

Tool Size and Availability

There are a lot of taps to choose from. Looking at just one type, straight flute taps, you’ll find tools for ultra-tiny #000-120 threads to tools big enough for 1-1/2”-6 threads, the latter nearly impossible to drive with anything but a high-horsepower, geared-head spindle.

Talk to Us!

The link for information on Emuge-Franken Soft-Synchro and FPC Tool holders is: https://www.emuge.com/holders/fpc-chucks

31Leave a reply

Your email address will not be published. Required fields are marked *