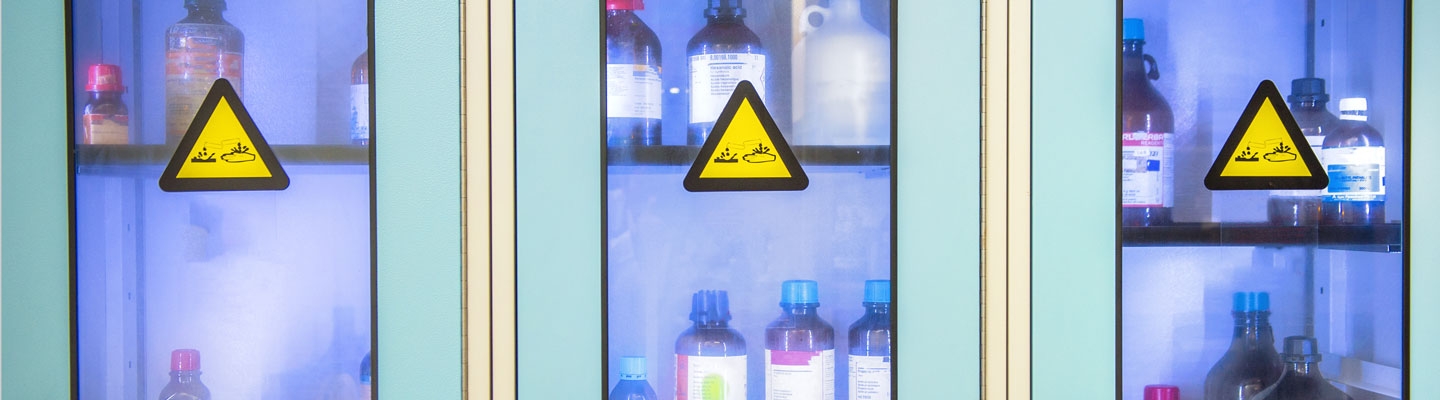

But navigating the various requirements for the handling and storage of flammable liquids can be complex. For example, how can you be sure that you are complying with the relevant regulations and fire codes, and when a flammable liquid storage cabinet is required?

In this comprehensive FAQ, we’ll review the standards for fire safety and safety cabinets as well as the types of products that are available to help with any manufacturer’s needs.

Read more: 5 Tips for Setting Up a Successful Microlearning Program in Your Facility

Question No. 1: What Are the Important Rules, Regulations and Guidelines That Apply to Flammable Liquid Storage?

The NFPA and the International Fire Code (IFC) have developed guidelines for the safe storage and use of flammable and combustible liquids.

- Published by the National Fire Protection Association, the NFPA 30, Flammable and Combustible Liquids Code, provides safeguards to reduce the hazards associated with the storage, handling and use of flammable and combustible liquids.

- The association also publishes the NFPA 1 fire code, which advances fire and life safety for the public and first responders as well as property protection by providing a comprehensive, integrated approach to fire code regulation and hazard management.

- The International Fire Code presents minimum safety guidelines for new and existing buildings, facilities, storage and processes.

These guidelines are only mandatory if a federal, state or local authority chooses to adopt them into law.

The Occupational Safety and Health Administration (OSHA) has federal regulations on flammable liquids that they enforce, such as 29 CFR 1910.106 General Industry Regulations and 29 CFR 1926.152 Construction Industry Regulations.

Facilities should check with their insurance providers and local authorities to confirm which fire codes apply in their locations.

Read more: Flammability Limits: How to Reduce Fire Hazard Risks in Your Facility

Question No. 2: When Should I Use a Flammable Liquid Storage Cabinet?

According to OSHA, amounts of flammable or combustible Category 1 liquids greater than 25 gallons must be stored inside a storage cabinet in approved containers.

As a blog by industrial safety products provider Justrite Safety Group notes, OSHA’s flammable liquids standard also sets the following volume limits on flammable liquids:

- The limit for a single storage cabinet is 60 gallons of Category 1, 2 or 3 flammable liquids, or 120 gallons of Category 4 flammable liquids.

OSHA places flammable and combustible liquids into four different categories based on properties such as flash and boiling points. Refer to OSHA’s 1910.106(a)(19) for definitions of the four categories.

A flash point is the lowest temperature at which a liquid can form an ignitable vapor. This is how OSHA and the fire codes classify or categorize flammable liquids to manage risk. The lower the category, the more volatile the flammable liquid. The lower the category, the smaller the allowable container size. The lower the category, the smaller the maximum allowable quantities

A boiling point is a temperature at which a liquid’s vapor pressure is equal to atmospheric pressure, and there is an even exchange of molecules between both.

Read more: PPE Assessment Plan: Selecting the Best Type for Your Business

Question No. 3: Where Should I Place My Industrial Safety Cabinet?

To avoid combustion, place your safety cabinet in a location that is far away from panel boards and electrical outlets. The cabinet should also be far from locations where there is welding or grinding activity, and far away from smoking areas.

Keeping safety cabinets away from areas that are likely to affect emergency evacuations is also important.

If a fire breaks out near the cabinet, it can endanger the lives of your workers by making emergency escape routes difficult to access. Consider avoiding locations under stairways, or in exit paths.

And while it may be tempting to keep your safety cabinet on pallets, as that’s most likely how it’ll arrive at your facility, doing so is not the way the safety cabinet was tested or approved and would not be allowed by authorities.

Question No. 4: Which Safety Cabinet Is Best for My Needs?

There are various types of models for different facilities and uses.

For example, an under-counter model could be the safest choice for a laboratory worktop, while a facility that needs a cabinet that fits into a tight space could decide to use a slimline model, notes Justrite.

A safety cabinet with self-closing doors may be the safest option for a facility, as it eliminates the problem of employees forgetting to close the doors when they use the cabinet. If a fire occurs, employees won’t be able to reach the cabinet to close it.

When you use flammable safety cabinets with self-closing doors, the fusible links melt when the temperature hits 165 degrees Fahrenheit, causing the doors to close.

EN flammable safety cabinets offer extreme fire resistance for high-risk environments by protecting volatile contents for up to 90 minutes, depending on the model, allowing for increased evacuation times and providing more time for emergency responders to control a fire before it reaches the cabinet’s flammable contents. Check with authorities to ensure these cabinets are acceptable in your area.

Question No. 5: Do You Need to Ground a Flammable Safety Cabinet?

You should always ground a safety cabinet and in turn the containers inside when you are dispensing from those containers inside the cabinet.

Grounding a container minimizes the risk of static electricity discharge, which can ignite a flammable liquid’s vapor and lead to a fire.

Many flammable liquid safety cabinets include exterior grounding lugs, which you should use when Category 1, 2 or 3 with a flashpoint below 100 degrees Fahrenheit flammable liquids are dispensed within your safety cabinet.

“Grounding is also a good idea when dispensing all other category liquids when heated to within their flashpoints from a storage or process condition,” according to Justrite.

Question No. 6: Are There Specific Design Requirements for Flammable Safety Cabinets?

OSHA requires that metal cabinets for flammable materials conform to specific requirements, including:

- A cabinet’s top, bottom, door and sides must be at least No. 18 gage sheet iron, and double-walled with 1.5 inches of airspace.

- Joints must be riveted, welded or made tight by some equally effective means.

- The door of the cabinet must include a three-point lock.

- The door’s sill must be raised at least 2 inches above the bottom of the cabinet.

Read more: These Wearable Tech Innovations Improve Workplace Health and Safety

Question No. 7: How Do I Choose the Right Container?

You should only use containers approved by OSHA to store flammable liquids.

Containers are generally made of metal, plastic or glass, but the type of container you use depends on the flammable liquid and its compatibility with the container’s material. For example, do not use a metal container if the flammable liquid could cause it to corrode.

The size of the container matters, too, as the amount of flammable liquid it can hold depends on the category of that liquid and the material the container is made of. Refer to 1910.106(d)(2)(iii)(b) for information about container type and maximum allowable size.

Flammable liquid containers should be properly labeled.

What important questions do you have about cabinets to safely store your flammable materials? Let us know in the comments below.

Talk to Us!

I was just wondering if I was able to mount some casters onto the bottom of our flammable cabinets? I'm assuming not because of the potential of static electricity buildup.

27Leave a reply

Your email address will not be published. Required fields are marked *