Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

Whether it’s sports championships or raising teenagers, few of us would deny that teamwork is a critical component of success. But nowhere is this more true than in undertakings where human lives are at stake. So when Steve Fonteyne, lead manufacturing engineer at aerospace solutions company Aerojet Rocketdyne, called Sandvik Coromant’s Derek Smith for assistance with a particularly difficult workpiece, of course the answer was yes.

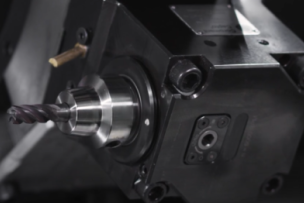

Smith is a process specialist and CAM programmer for Sandvik Coromant’s global aerospace and custom solutions group. For nearly five months he was on site at Aerojet Rocketdyne’s manufacturing facility in Canoga Park, California, in the United States. Together with CNC programmer George Hernandez and machinists Enrique Guzman and Gurjit Matharu, Smith developed the complex code needed to drive the company’s five-axis machining center. He and the Aerojet Rocketdyne team tested the tooling, simulated the manufacturing processes and worked ever so carefully to bring the workpiece to completion.

You’ve probably seen the Aerojet Rocketdyne Space Shuttle main engine. It was a pillar of the NASA Shuttle program for the program’s entire 30-year mission and was used to launch astronauts into orbit 135 times. It generates temperatures of several thousand degrees Celsius and produces enough thrust to lift 10 blue whales. It is currently being repurposed as the RS-25 engine for NASA’s next great deep-space exploration rocket, the Space Launch System, tasked with taking humans back to the Moon and ultimately to Mars.

This is one reason why Aerojet Rocketdyne management reached out to Sandvik Coromant; the company wanted help with the machining of the RS-25’s main combustion chamber (MCC), one of the many critical components of a now-legendary rocket engine, constructed of materials robust and heat-resistant enough to withstand the hellish conditions produced within its fiery core.

There’s more to this story than machining a particularly difficult metal, however – something that everyone involved in the project was already quite familiar with.

What made this project unique was a timeline that allowed for no delays, a workpiece that was worth hundreds of thousands of dollars by that point, and a host of additional challenges that, even taken individually, would have been a sufficient cause for concern. These include a variety of new cutting tools and tool holders, new programming software, a new machine tool and an as yet untested machining process. To say the project was a nail-biter is like saying rockets are sort of fast.

This is not the first time that Sandvik Coromant has assisted with an undertaking like this. In 2014, technical sales representative Jim Courtney was involved in a cycle-time reduction project that allowed Aerojet Rocketdyne to avoid investment in several machine tools and ultimately bring a family of subcontracted parts back in-house.

The MCC project was equally successful. After extensive checking and rechecking of their mission parameters, Smith and Hernandez completed the final machining cycle early in 2018. The combustion chamber was then sent to NASA’s Stennis Space Center in Mississippi and attached to a newly designed RS-25 engine for testing, where it far surpassed expectations in the first of eight full-scale ground tests.

Everyone loves rockets, but none more so than those who were instrumental in manufacturing them. Aerojet Rocketdyne employees Hernandez, Fonteyne, Guzman, Matharu and countless others deserve the highest of kudos for their accomplishment, as does Sandvik Coromant’s Smith. If not for the months of late nights and occasional weekends, never mind the fact that no mistakes were made through the course of this months-long project, it’s entirely possible that humanity’s next big step in space exploration might have met with delays or worse.

Previously Featured in Metalworking World.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *