Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

Sandvik Coromant offers higher productivity for milling nickel-based alloys.

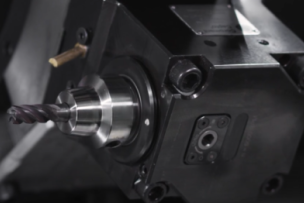

Cutting tool and tooling systems specialist Sandvik Coromant has released two series of ceramic end mills for optimized performance in nickel-based alloys. The latest brazed ceramic CoroMill® 316 and ceramic CoroMill® Plura end mills offer a more productive method for roughing in ISO S materials compared to standard carbide milling cutters.

With aerospace components manufactured from nickel-based alloys becoming increasingly prevalent, the demand for optimized cutting tools is growing. With this in mind, Sandvik Coromant has developed two innovative solutions that are ideal for the shoulder and face milling of nickel alloy aeroengine parts.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *