Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

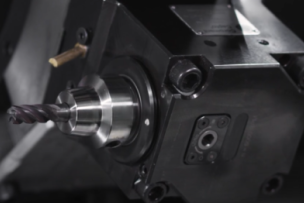

Challenging machining places high demands on insert grades for turning heat resistant super alloys (HRSAs) and titanium. Machinability of HRSA-materials increases in difficulty according to the following sequence: iron based materials, nickel based materials and cobalt based materials. All the materials have high strength at high temperatures and produce segmented chips during cutting which create high and dynamic cutting forces.

Poor heat conductivity and high hardness generate high temperatures during machining. The high strength, work hardening and adhesion hardening properties create notch wear at maximum depth of cut and an extremely abrasive environment for the cutting edge.

Carbide grades should have good edge toughness and good adhesion of the coating to the substrate to provide good resistance to plastic deformation. In general, use inserts with a large entering angle (round inserts) and select a positive insert geometry. In turning and milling, ceramic grades can be used, depending on the application.

How do you find the right solution for your HRSA or titanium turning operation?

The Sandvik Coromant grade assortment for HRSAs includes CVD and PVD coated carbide grades, ceramic and cubic boric nitride (CBN) grades for various machining conditions. Use the information below to find the right grade for your production requirements.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *