Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

The International Manufacturing Technology Show (IMTS) 2018 in Chicago, Illinois, is quickly approaching, from September 10 to 15. Whether you’re attending for your first time, or you’re an IMTS veteran, there is always something that will leave you in awe.

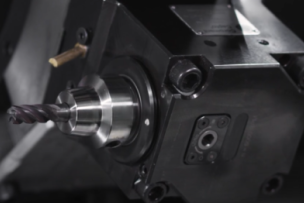

If you’re planning to attend in order to find new tools and technologies to put you ahead of the competition, be sure to visit the Sandvik Coromant booth. Shaping the future together is their theme for IMTS 2018 and it represents the engineering solutions and technical expertise available to help customers overcome current and future machining challenges.

Presented at IMTS will be Turning Reinvented, which includes products such as the new Y-Axis parting offer and PrimeTurning solutions. The new CoroCut QD blade for parting-off operations, which improves stability during cutting and realigns the cutting force by feeding in the Y axis direction, will also be showcased. PrimeTurning, which you may be familiar with, includes the introduction of two dedicated CoroTurn Prime tools and the PrimeTurning code generator, which supplies optimized programming codes and techniques. CoroTurn Prime inserts have three edges per corner, one edge each for longitudinal, facing and profiling thus distributing the wear over a longer edge and not just the insert tip.

If you’re looking to optimize your factory for the future with Industry 4.0 solutions, look no further than the leading edge CoroPlus solutions from Sandvik Coromant. If you’re looking to cut time choosing the correct tool for your application, choose CoroPlus ToolGuide, which provides quick and accurate tool recommendations based on a given task and material. CoroPlus ToolLibrary allows users to integrate tool assemblies directly into their CAD/CAM digital environment. Another solution to be showcased is CoroPlus Process Control, which allows customers to increase control of their machining process through the implementation of hardware and software solutions inside their machines. Other IIoT solutions to discover will include CoroPlus Collision Detector, CoroPlus ToolGuard and CoroPlus Machine Health Inspector, which are ready to be implemented in your shop today to increase your differentiation from the competition.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *