The Boeing 787 Dreamliner entered commercial service on October 26, 2011, with launch customer All Nippon Airways. By June 15, 2014, the 787 Dreamliner had already flown more than 100,000 times and had carried more than 20 million passengers all over the world. If you have taken the 787 Dreamliner to some places you dreamed of.

Today, more than 350 787 Dreamliners are flying to destinations around the globe, with more on the way. The tremendous success of the Boeing 787 Dreamliner is based on its excellent flight performance and low-operating cost. The long-range, mid-size wide-body, twin-engine 787 Dreamliner can carry a maximum of 290 passengers and travel as far as 15,750km, which is about a third of the way around the Earth. It is also Boeing’s most fuel-efficient airliner, which is the result of being the first aircraft to implement composite materials as the primary material in the airframe. Boeing listed its materials by weight as 50 percent composite, 20 percent aluminum, 15 percent titanium, 10 percent steel and 5 percent others. According to Boeing, the lightweight construction had contributed to the 787 Dreamliner’s ability to cut down on fuel consumption by 20 percent versus previous models, which can decrease the emission of greenhouse gases to our environment.

In China, Boeing Tianjin Composites Co., Ltd (BTC), a joint venture of The Boeing Company and Aviation Industry Corporation of China (AVIC), produces components for all of Boeing’s in-production commercial airplanes, including the 787. Based in Tianjin, China, BTC is equipped with some of the most advanced aero composite material production machines and laboratories. It is dedicated to the manufacturing of aerospace composite parts for primary structure, secondary structure and interiors parts of commercial aircrafts. As an industry leading tool manufacturer, OSG provides cutting tools to the aerospace industry, including BTC’s 787 program.

Composites are used on the 787 Dreamliner’s fuselage, wings, tail, doors and the interior. Composites are corrosion-resistant, stiff and strong material composed of mixtures of fiber. They have three times the tensile strength than steel, yet their density is half of aluminum alloy and is only a fifth of the weight of steel. These characteristics make composite materials very popular in the aerospace industry.

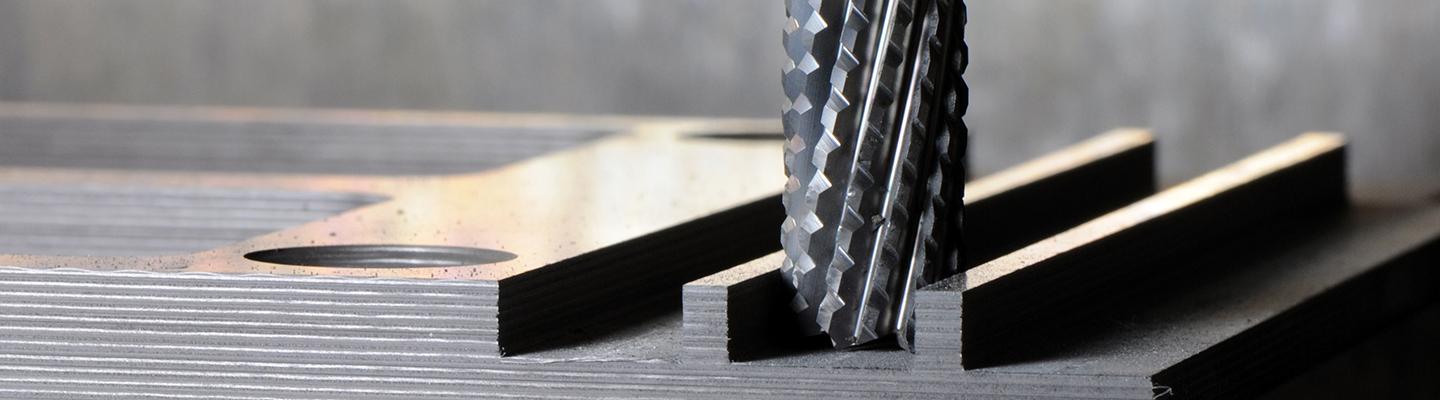

Machining composites often involves a high degree of difficulty because of their multilayer properties. High material strength may also lead to shorter tool life. In addition, poor hole quality is commonly present in aerospace applications because of a condition called delamination, which is the splitting of a laminate into layers. As the aviation industry holds high quality and safety standards, these conditions are unacceptable and manufacturing requires proper tooling that can do the job right – on the first try.

All of OSG’s composite tooling features metallurgy and cutting geometries to help increase productivity, reliability and tool life while reducing machining time and scrap. OSG also offers a patented ultra-fine diamond coating, which is a prerequisite when machining composites and provides a definitive advantage over other manufacturers’ diamond coated products.

OSG’s patented ultra-fine diamond coating has a maximum diamond grain size diameter of 2 µm. This strictly controlled diameter allows our coating to be super smooth and tools to remain extremely sharp. OSG also manufactures all diamond products in-house with absolute control. The end result is a diamond coated product in which tool life can be consistently predicted, rather than having to endure premature diamond delamination issues.

In China, OSG has the recognition of AVIC, which can be translated to having recognition from Chinese aerospace manufacturers. OSG is not only a company that simply provides tools, but also supports the daily lives of people around the world. Maybe you are not aware of our presence, but we do work diligently to contribute to society and to shaping your dream flight.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *