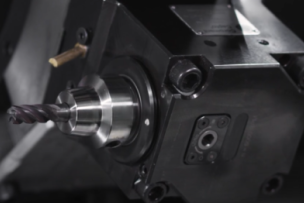

CoroMill® products have shaped the landscape of milling, with light cutting inserts, different pitch options and hardened cutter bodies, CoroMill® tools deliver value to your milling operation.

Since its introduction over 20 years ago, CoroMill® products have shaped the landscape of milling. With light cutting inserts, different pitch options and hardened cutter bodies, CoroMill® tools deliver value to your milling operation. With constant refinements, the CoroMill® family remains at the leading edge of milling-tool development.

Offering more than 6,500 cutters and 2,900 different inserts, any product from the CoroMill family will consistently improve your machining operation. From shoulder milling to profile milling, you can find an optimal cutter here.

For mixed production with a variety of component features and materials, CoroMill 390® cutters are your “go-to” cutter. With an assortment including many different types of tools and a wide selection of corner radii and insert sizes for various cutting depth requirements, the reliable CoroMill 390® can mill almost any shape you require.

- Diameter: 0.375 – 8.000 inch

- Maximum cutting depth: 0.618 inch

From roughing to finishing, the CoroMill® 490 is your first choice for general and repeated shoulder milling offering light-cutting, positive concept with four cutting edges. Precise cutter bodies and insert location along with a low-vibration machining process provide accurate shoulders without mismatch.

- Diameter: 0.750 – 10.000 inch

- Maximum cutting depth: 0.394 inch

The unique differential MD pitch of the CoroMill® 745 is your first choice in roughing operations where light cutting action is required; such as vibration-prone or weak setups. The CoroMill® 745 offers multi-edge, doubled-sided inserts with the cutting performance of a positive single-sided concept. Available in both a 42-degree lead, as well as 25-degree lead.

- Cutting edges: 14

- Diameter: 2.500 – 12.000 inch

- Maximum cutting depth: 0.205 inch

The light-cutting action of the CoroMill® 300 allows for smooth entries and exits and for use of extended tool set-ups. Available in neutral and positive design, is uses round inserts and offers a light-cutting action and is your first choice from roughing to semi-finishing.

- Neutral design:

- Diameter: 0.375 – 1.25 inch

- IC05 to IC16

- Positive design:

- Diameter: 1-8 inch

- IC08 to IC25.4

No other grooving cutter features the innovative internal coolant solution and damped adaptors that make CoroMill® QD the first cutter of its kind. Your first choice for narrow, deep grooves, it offers optimized milling grades and E-tolerance inserts for controlled chip evacuation, leading to high-quality grooves with tight tolerances provide for a predictable tool life.

- Cutting width: 0.079 – 0.250 inch

- Diameter: 2.5 – 12 inch

- Maximum cutting depth: 4.429 inch

- For mixed production with a variety of component features and materials, CoroMill 390® cutters are your “go-to” cutter.

- CoroMill® 490 is your first choice for general and repeated shoulder milling offering light-cutting, positive concept with four cutting edges.

- The CoroMill® family remains at the leading edge of milling tool development.

Shop for the CoroMill® Cutter here.

Brought To You By

Sandvik Coromant is the world’s leading supplier of tools, tooling solutions and know-how to the metalworking industry. With extensive investments in research and development they create unique innovations and set new productivity standards together with their customers. These include the world's major automotive, aerospace and energy industries.

More from Sandvik Coromant

More on How-to

Toolholders are the most important connection between the machine and cutting tool. High-quality toolholders can extend tool life and save you money.

In this episode of MSC Industrial Supply's "How To," host Jacob Sanchez explores the cutting-edge world of tooling and machining innovation with Mitsubishi Materials.

In pipeline construction, properly preparing and cleaning the base material is the first step toward ensuring quality welds and minimizing defects.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *