Narrator: This video is brought to you by Walter USA LLC. Walter is Engineering Kompetenz. If you're looking for real world insights, tips from leading industry experts, the latest trends in products and technology, you've come to the right place. From MSC Industrial Supply, this is Tooling Up.

Toni Neary: Hello and thank you so much for joining us on Tooling Up. I'm your host, Toni Neary. I'm so happy that you're here with us. Don't forget to like this episode and click the subscribe button if you're new here on the MSC YouTube channel. We're going to have a great conversation today. I'm so excited to be joined by Brian Baker, a product manager with Walter Tools. Brian, thanks so much for joining us today.

Brian Baker: Hey, thank you Toni for having me.

Toni Neary: Absolutely. And one of the things I love to take a deep dive into right off the bat, tell me a little bit about your experience, kind of your trajectory that landed you in the role that you're in right now at Walter.

Brian Baker: Okay. Well well, right now at Walter, I am the product manager for all milling and threading products for the United States and Canada. But I've been in this industry for a very long time. I started basically right in while in high school, co-op, working in machine shops, and I worked my way up from operator, programmer, plant management to pretty much anything in between.

Toni Neary: And I have to say, having that sort of background and that knowledge from being on the shop floor in a sales role and now actually helping to figure out what products are going to launch and how they're going to go to market and how they best serve your customers, is pretty impressive. It has to give you a different perspective over all those years.

Brian Baker: Oh, it definitely does, because I've been there. I've been on the shop floor and I've known what, you know, I wish I had, you know, to get the job done. And then I was in sales and I always wished that we had the right product to help those customers, my customers. And then now I'm in a position where I can help, you know, mold what our product line actually is and get the correct products out to the shops.

Toni Neary: And knowing all of those different angles, because you're not just looking at application, you're looking at cost effectiveness, you're looking at longevity, how is that influenced when you're looking at new products and what goes into that?

Brian Baker: Well, you always have to come up with new products and you always have to move forward. If you're not moving forward, you're falling behind. And that's one thing that we really strive for over at Walter is having a very high ratio of brand new products out there for the customers.

Toni Neary: And how does that process work? Like, how do you decide it's time to revamp an existing product or enter a new one into the market? How does that really kind of kick off for you?

Brian Baker: We look at some of our older products and see if they're still relevant. If we're getting beaten more, there's a better way of doing it, we're going to develop that and bring that to the market.

Toni Neary: So I know something that's really important at Walter is training. Can you talk a little bit about the exciting new facility that you have rolling out next year?

Brian Baker: Yeah, we are building a brand new technology center. This is going to be down in Greer, South Carolina. It's in the process. It's in the works. We're already have the machine room up and running. We have machines on the floor. And when we get the training center done and we're able to bring customers in and bring some of our channel partners in as well and start conducting the training on practices, our products, best methods, it's going to be really exciting.

Toni Neary: Well, and I think it's important when we're looking at the market, you know, you are making strides. You're a German-based company, but looking at this acquisition, we're also looking at the opportunity that now you're serving a bigger market globally, correct?

Brian Baker: Exactly. And one of the big focuses we have right now is on the North American market. When we acquired this manufacturing facility, which is here in the United States, we launched a very dominant inch-based product line, which is very unheard of from, you know, our company with its heavy German roots. We've added over 3000 inch solid carbide end mills to our North American offering, where before we had less, you know, less than 350.

It's a major investment moving forward and a major step to take care of the business right here at home.

Toni Neary: And I think it's important that, you know, when you're looking at the U.S. market, we do have a mix, right? We have a mix of imperial, and then we have the metric system as well. So this, I imagine, would serve a huge customer base for you.

Brian Baker: Oh, it does. It just expands our offering, increases the breadth so people don't have to change and they can just keep running and just go to a better product and that's what we are striving to do, is always offer a better product.

Toni Neary: And I think you got a little creative with this acronym as well for the Universal Super Alloys, Aluminum Alloys, right, with standing for USA and now having the U.S. manufacturing facility.

Brian Baker: Exactly. And that's really hitting home with a lot of customers out there right now, too, because these products are made in the United States. They were engineered in the United States. They were developed with research and development here in the U.S. and they're stocked in the U.S. So, these products are really hitting home with a lot of people and as far as the acronym is concerned, I looked at the offering that we had. About a third of it was universal tools. About a third of it was for super alloys, and about a third of it was for aluminum. And just by writing that down, we came up with USA.

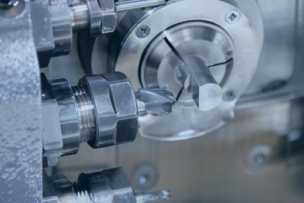

Toni Neary: Let's talk a little bit about the features, because this is always where we can show some really cool footage of making chips and the products actually at use. Tell us some of the key features for the new products that you've got.

Brian Baker: Well, first off, we hand-selected this offering that we're coming out with for our market and what we are doing here in North America. The universal line is specifically targeted for steels and cast irons, but it can be used in a whole plethora of other materials as well. But we still are one of the largest manufacturers and machining markets for steels and irons out there, so definitely that's something we had to tackle.

In addition, the market is changing. Aluminum is booming. It is expanding rapidly. So we have one of the most comprehensive lines of mills designed for aluminum that's out there. So many sizes, corner radii, ball mill versions with chip splitters without. There's just so many out there for aluminum applications that we're going to be in a great situation.

And then finally, the super alloys, the manufacturing in the usage of titanium, high-temperature, heat-resistant alloys, nickel-based materials is growing as well. And the offering that we have in there is just spectacular.

Toni Neary: Brian, it's been great chatting with you today. I can't thank you enough for taking the time with us.

Brian Baker: It's been a pleasure being here. Thank you.

Toni Neary: I'm so glad we had a chance to meet with Brian today. I think it's so interesting just to see the very backgrounds that we see on our guests on Tooling Up, to see what the organizations are doing to really grow adoption, and the investment and training that Walter has made is just mind blowing to me. I love to see organizations that are so committed to really furthering our industry.

If you enjoyed this conversation as much as I did, make sure you click subscribe so you don't miss any upcoming episodes. And if you'd like to take a look at some of these new product lines available, go to www.mscdirect.com/walter-usa. Thanks so much and we'll see you next time on Tooling Up.

Narrator: Want more insights and ideas to improve the efficiency and productivity of your operations? Check out the Tooling Up video playlist to hear tips that can take your company to the next level. And subscribe to our channel so you won't miss out.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *