Seco is one of the world’s largest providers of comprehensive metal cutting solutions for milling, stationary tools, holemaking and tooling systems. For over 80 years, we have been more than just a cutting tool provider. We develop and supply the technologies, processes and supports that manufacturers depend on to maximize productivity and profitability.

Not all 2 and 3 flute solid carbide end mills are created equal, but they are by far the most used end mills when it comes to milling nonferrous materials such as aluminum. Harmonics, chip evacuation, chatter and surface finish quality can easily become a big problem due to the machinability and setups associated with machining aluminum components.

-

Need for speed but watch out for chatter bumps

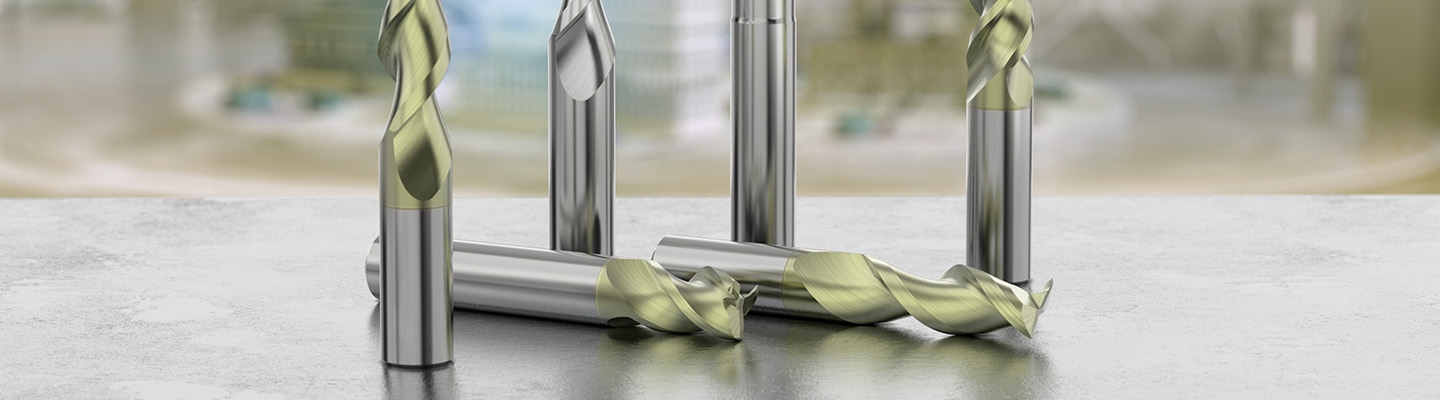

Because aluminum is free machining, it gives the illusion that you can program max rpm and max feed rate on your CNC machines and everything will work out just fine, right? Unfortunately, chatter, vibrations, harmonics, etc… tend to creep in and leave us scratching our heads in disbelief. Seco’s new A245/A345 product families are uniquely designed to address these major issues by incorporating a cylindrical margin on the OD, coupled with a unique flute shape and high shear geometry. These end mills reduce power consumption and cutting pressure, while increasing chip control. By using the A245/A345 end mills when machining aluminum, you can increase your feeds and speeds without sacrificing surface finish, resulting in reduced cycle times and increased productivity.

-

Why so serious about chip control?

Chip control is a major issue when it comes to machining aluminum. Aluminum by nature is what some people call “gummy” or “sticky”, which causes built up edge (BUE) when milling, drilling or tapping. BUE can cause premature tool failure, surface quality issues and even increased power consumption. Keeping BUE in mind, our engineers at Niagara Cutter, a Seco Tools Company, developed a truly unique polished K-land, using a new PVD style coating called Aluminum Non-Ferrous (ANF) on the radial rake face to help reduce and, in some cases, even eliminate BUE entirely.

-

As they say, happy coolant, happy life!

With all the different types of water soluble and oil-based coolants in the industry, it can be hard to determine which coolant is best suited for your specific needs.

Pro-tip: Taking the time to do some research online or talking to your colleagues in the industry can help narrow down your selection. Reach out to your Seco Tools technical specialist for additional support!

Once you’ve identified the right coolant for your application, it is crucial to follow the manufacturer’s recommendation when it comes to maintaining the proper concentration levels and establish a coolant maintenance/care plan. Failing to do so can result in lost production due to inconsistent tool life caused by BUE, part quality fluctuations and overall cost increases.

-

Hold on

No matter which material you are machining, you cannot overlook the importance of using good quality tool holders. Milling chucks, high-precision collet chucks and shrink fit holders will help ensure consistent tool life, surface finish quality, tolerance and overall throughput. Establishing a preventive maintenance plan to ensure that your holders are properly cleaned and well maintained will have a positive impact on your bottom line.

Machining aluminum brings its own set of challenges for all manufacturers. Most industry segments including Aerospace, Automotive, Medical and General Machining manufacture components made from this “easy” yet sticky and gummy material. With the unique features of the newly launched A245/A345 end mills from Niagara Cutter, including a polished K-land, ANF PVD coating and cylindrical margin, you can solve the common problems associated with aluminum machining and improve your applications.

.jpg?itok=clvY6OP5)