NARRATOR: This video is brought to you by Walter Tools, a provider of specialized machining solutions. Welcome to Tooling Up, a series by MSC Industrial Supply Company, the show that provides real world insights and is brought to you by leading industry experts aimed at improving the efficiency and productivity of your operation. And now, the host of Tooling Up, Mitch Free.

MITCH: Hello and welcome to Tooling Up. Before I introduce today's special guest, I want to encourage you, if you haven't already done so, to subscribe to the MSC channel, where you can find products and technologies, as well as gain valuable insights from industry experts. With that, I'm excited to jump right in and introduce the product manager of Walter USA, Sarang Garud.

Sarang has worked in the cutting tools industry pretty much his whole career, first specializing in CAD, then working with deep hole drilling machines as the applications engineer. And now he finds himself managing, drilling and turning products for Walter's U.S. and Canadian markets. Thanks for joining me today, Sarang.

SARANG: Hey, happy to be here, Mitch. How are you doing?

MITCH: I am doing fantastic. No pun intended, but I'm excited to drill into today's topic. I’m sure you've never heard that before.

SARANG: Absolutely, let’s drill in.

MITCH: Could you share a little bit about your background?

SARANG: Yeah, absolutely. I got my bachelor's in India in mechanical engineering, and I came here for my master's. And I came here actually for a slightly different field in mechanical engineering for finite element analysis and computer engineering, CNC, you know, simulation side of things. But as I started taking those courses, I found myself really attracted to the production side of things. I could get the math so easy and the whole thing was so much fun. So I kind of morphed my research into machining and finite element analysis together. So that's how I got going on this side of our field.

MITCH: So you started off more in the CAD software side and then once you started getting your hands dirty and seeing the real world applications that attracted you. Can you tell us a little bit about Walter USA, sort of the product line?

SARANG: Yeah, Walter USA is a global manufacturer of cutting tools. It's very well known all across the world as, you know, drilling, milling, turning, grooving – all of these tools.

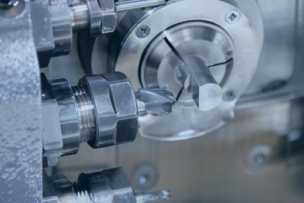

MITCH: Well, I recently learned that you guys have a drill called DC160 and, honestly, I didn't know there was a lot of innovation left in drilling, but you guys seem to be just out of the box innovating. I'd love to know more about that DC160 drill.

SARANG: One of the great things about DC160 is it's a universal drill. So yeah, as you said, I mean, at some point of time it's just a drill – how much can you innovate? Well, you can, it turns out. Because this drill can go from three times diameter up to 30 times diameter.

MITCH: Did you say 30 times diameter?

SARANG: 30 times diameter. And we have some tools that go 50 times or even 70 times. But this one and the standard product line, we go up to 30 times diameter, that's pretty deep. Pretty large range of diameters, three millimeters to 30. And it's a universal drill.

MITCH: So yeah, so I know people are thinking, sure, you can take a small, long drill, you know, drill a deep hole, but can you keep it straight? Can you hold the diameter?

SARANG: Yeah, absolutely. It's a double-margin drill. So if there are two cutting areas, each cutting edge gets two margins. So it’s technically a four-margin drill. So it's very good support. And what we have done over the previous product is and the last product was extreme drills, that was wildly popular globally. It was very famous, very popular. A lot of customers love it.

What we've done now is you've got the secondary margin forward. So actually the second margin engages much faster than it used to and compared to a lot of competitors. That means if you're going down deep in the drill right at the beginning, instead of going this way, it just centers right in. It zeros right in. It's supported really well. So you get very good true positioning tolerance, so on and so forth.

MITCH: And that's the key, getting it centered right off the bat.

SARANG: That’s exactly right, exactly.

MITCH: So the innovation really is in the geometry at the tip then?

SARANG: Absolutely. Innovation is right there. Innovation is also that deep chip gash. So the chips come off well. And I said, this is a universal drill. So what we do have, Walter has a large amount of product. We have 49,000 items in our catalog. We have a lot of drills. Some are very specialized for only steel, only stainless steel, so on and so forth. But this one we design by choice to be a universal drill so it can do steels, cast irons, stainless steel, super ionized, aluminum. So we designed it for people such as yourself who have shops that do general-purpose machining, that do specific purpose, automotive supply, or aerospace supply or even big earth-mooring equipment OEMS or even automotive or aerospace guys, they use it too. So everybody can use it.

MITCH: You are destroying the myth that a drill bit’s a drill bit and that there's no innovation left. It's incredible the innovation in, you know, in the DC160, but actually all of Walter's product line. I mean, you guys are really out there on the edge thinking of ways to increase productivity, extend tool life, improve accuracies. Walter, it's an impressive organization.

SARANG: That's right. We pride ourselves with our engineering competence, as we call it, and that competence is paired with brave German roots our company is based in. We are a global company, with German roots, and that's really that engineering competence, that pride engineering and doing just those small little things with extreme detail to get it right. That's what we really are good at.

MITCH: Sarang, I want to thank you for joining us today. It's been really insightful learning about some of the innovation in deep hole drilling. I know you guys do a lot more than that, but I just found this DC160 product and the innovations there to be fascinating as well as your passion for hole making.

SARANG: Thanks Mitch. Thanks for the conversation. It was really nice.

MITCH: I want to thank you for joining us today. To find out more about the DC160 carbide drill and other solutions from Walter Tools, just head over to mscdirect.com/waltertools. You'll find that link in the description below. Remember, some of the best suggestions come from you, the Tooling Up community. So absolutely connect with us in the comment section below and let us know some of the holemaking challenges that you're experiencing on your shop floor.

Until next time, MSC's Tooling Up is here to help you be a better, more efficient and productive manufacturer. We'll see you soon.

NARRATOR: Want more insights and ideas to improve the efficiency and productivity of your operations? Check out the MSC Tooling Up video playlist to hear tips that can take your company to the next level. And subscribe to our channel so you won't miss out.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *