Stereolithography inventor and 3D Systems founder Charles Hull began selling 3D printers in 1986. A few years later, Scott Crump of Stratasys commercialized his fused deposition modeling technology. Others soon followed, and it wasn’t long before entrepreneurs everywhere were buying these “rapid prototyping” machines and opening “service bureaus,” companies that focused solely on 3D printing.

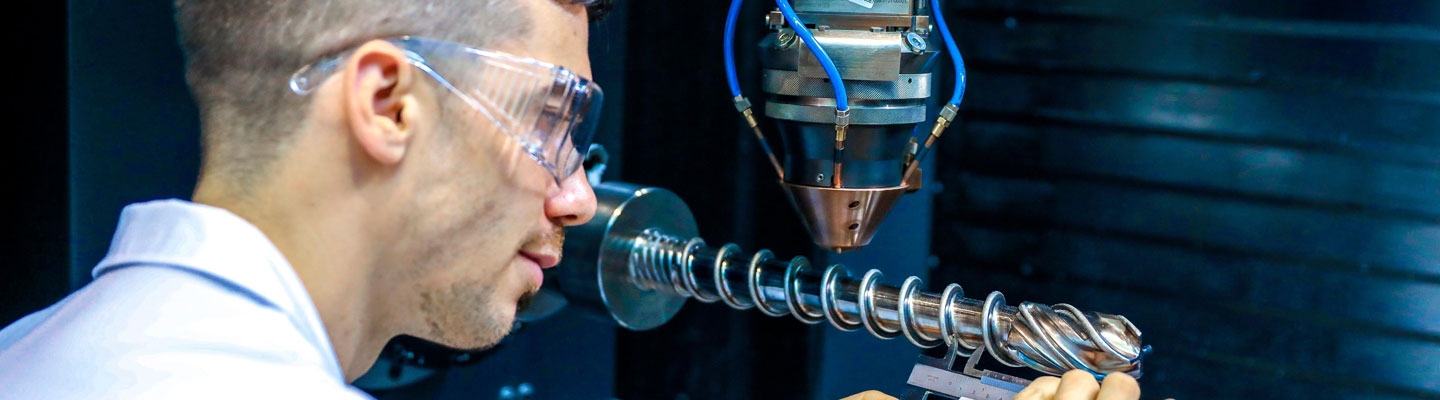

Today, each of those once cutting-edge terms is mostly obsolete. Additive manufacturing is no longer limited to prototyping, rapid or otherwise. And service bureaus have given way to e-manufacturers, whose owners and managers maintain that 3D printing complements CNC machining and other more traditional manufacturing processes, and has become just another tool in their toolbox (albeit a very powerful one).

Compensating for strengths and weaknesses

That’s certainly the case with Los Angeles-based Stratasys Direct Manufacturing, where vice-president of operations Greg Reynolds explains that deciding what manufacturing technology to use for any given project depends on numerous factors, beginning with part complexity.

Talk to Us!

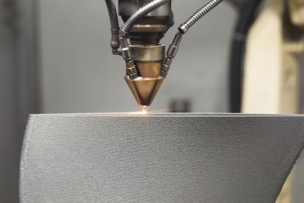

Additive manufacturing of metal components will not produce the microstructure needed for most load carrying components, a drawback that is ignored by the community for reasons that I do not understand.

38Leave a reply

Your email address will not be published. Required fields are marked *