With a slew of end mills to choose from today, it's hard to decide which one is right for your production and your budget. In this video I'm going to introduce you to another OSG home run tool that will get you the high-efficiency productivity you're looking for in an unbeatable offering size.

Hey friends and fans of OSG, my name is Alyssa O'Brien, Product Engineer with OSG USA, and today I'm spreading the word about OSG's brand new tool series the VGM end mills. That stands for variable geometry multi-flute end mills. These are the hottest offerings on the block for high-efficiency machining. What is high-efficiency machining you ask? High-efficiency milling is also known as trichoidal milling or volume milling and is characterized by deep axial depths of cut along with relatively small radial widths of cut. With a super stable end mill like the VGM, this type of milling can allow the user access to a significantly higher level of material removal rates versus conventional methods, particularly when your part requires a lot of deep side milling or pocketing. The VGM end mills target a wide array of materials including carbon and alloy steel up to 45 Rockwell, stainless steel of all varieties, cast iron and high temp alloys like titanium and Inconel. In our in-house testing we've found that the VGM outperforms the competition in productivity across the board in steels and stainless applications. By how much? The OSG VGM end mill outlasted the competition in tool life by 10 percent to 30 percent or more.

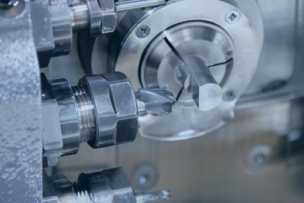

While the VGM is a stellar performing tool for side milling applications, it can be more versatile for you as well. Here's a look at the VGM doing some helical boring and pocketing. So you've seen the video footage and how the tools run, you've heard about the outstanding test results, now let's take a listen to what our customers are saying about these end mills to top it all off. One of our customers in Bensonville, Illinois using our VGM end mill not only improved their cycle time by over 20 percent but they also improved their tool life by 350 percent. Overall, the tooling cost per unit reduced by 75 percent. The customer states, "Wow, this end mill has outperformed better than any other end mill I have used." Another high-efficiency OSG customer in North Carolina cutting 836 steel was wanting to reduce their cycle time but still maintain a quality finish that could distinguish this customer's parts from their competition. With the VGM end mill they saw a three-minute cycle time reduction while extending their tool life through 75 parts. The customer stated "For anyone wanting to lower tooling costs from a dollar amount or from a cost per unit or cost per tool time in the cut, the VGM is the ticket. I've been fairly impressed with the VGM line and to be frank, it's hard to impress me." An OSG customer in Colorado looking to lower tooling costs on their 17-4 stainless parts saw the OSG VGM end mill not only improved their tool life but also improve the surface quality as well. The customer stated "VGM has filled a gap that tooling manufacturers have been missing for many years. It has become a staple item in our production process due to the available lengths and diameters and our ability to eliminate subsequent operations due to the high-quality surface finish it provides." Our customer in Oklahoma machining 42 Rockwell 718 Inconel was seeking better tool life and cycle time reductions. This customer stated "Best performance of any end mill we have tried on these Inconel parts. Less cost than the competitor and reduced cycle time per part from 28 minutes to 20 minutes. I will order the OSG half inch VGM 7 and 3/8 VGM 5 to also implement on these parts to reduce cycle time even more."

OSG offers 5 flutes, 6 flutes and 7 flute end mills and end cuts either corner radius or square end. We have length of cuts varying from 2 x D all the way up to 6 x D. That's some incredible depth-of-cut options. Across these lists ranging in diameter from one eighth of an inch up to one inch, OSG provides our customers with over 750 end mill EDP options and the icing on the cake, all of these are all manufactured and stocked here in the USA. If you've got any further questions or better yet, if you're excited to try out one of our new VGM end mills, don't hesitate to give us a call today. And, if you haven't done so already, please subscribe to our OSG's YouTube page for all of the latest and greatest OSG tooling solution videos. You can also connect with us on Facebook, LinkedIn, and Instagram. Thanks for watching friends and we'll see you guys next time.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *