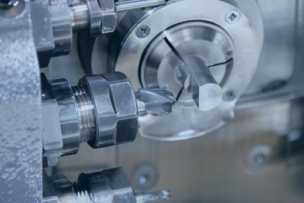

Hi, my name is Alyssa Walther, product engineer with OSG USA and today I want to talk about one of OSG's most advanced products for threading, OSG's AT-2 thread mill. This is such a unique thread mill because it does not require a pilot hole. It drills and threads the hole at the same time. So how does the AT-2 work? In essence, it's like an end mill where it has cutting teeth at the face of the tool. These cutting teeth allow the tool to bore into the material from solid, which means you are able to cut through a solid block.

On the outside diameter of the tool are the thread cutting teeth. The first tooth is a roughing tooth and is truncated slightly sharper from the major diameter of the thread. The next two teeth are finishing teeth that come in to clean and finish the thread to a 2B class of fit. The features of the AT-2 that allow it to bore into solid materials make it a great replacement for both a drilling and threading process, meaning in situations where you need to combine two processes into one, this tool can provide a great process improvement. Also, because the geometry of the AT-2 is so robust, it is able to cut steels up to 65 Rockwell and those are the materials that you're going to have the most trouble both drilling and especially threading. So, if you're able to replace both of these processes, save the headache of potentially needing to remove a broken tap from your part, why wouldn't you?

In situations where you have heavy scrap costs, the AT-2 is going to both prevent you from scrapping that part and allow you to replace two processes simultaneously. The biggest thing to keep in mind with the AT-2 is that this is a left-hand cutting tool. Make sure you're using M04 when programming. For programming, you're essentially going to program this like an end mill's helical boring cycle. Just make sure that your ramp angle is set to be the pitch of the tool. So, for a quarter 20 you're looking at an axial depth of cut of 50 thou per pass. Additionally, these tools are not extremely fast but they are very safe. So, if you're in a situation with a softer material, you can still use the AT-2 but recognize your process improvements aren't going to be extremely high.

One of the most common questions about the AT-2 thread mill is "What materials do you recommend this for?" The biggest one is hard steels up to 65 Rockwell. However, because of the cutting geometry of the tool we can use this on a variety of materials. If you want to use this on 1018 mild steel, you can do that. If you want to use it in Inconel or titanium, it'll handle those materials as well. So in any case this tool is a good replacement for drills and taps in those materials.

OSG offers our AT-2 thread mill in a size ranging from number eight to half inch or M3 to M12. If you're ever in a situation where you need something that's going to replace both a drill and a tap, especially in those hard materials, the AT-2 thread mill is the solution for you. For more information, please visit osgtool.com and feel free to contact us with any questions.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *