In a Case Study on the Series 51 T-Carb conducted by KYOCERA SGS Precision Tools, an aerospace customer saw a total savings of almost 40%. The goals of this study were to significantly reduce job cost through reduced cycle time, increasing MRR and reducing total machining time. KYOCERA approached this job with a 6 flute T-Carb end mill, which excels at high-speed machining. Specifically, trochoidal and peel milling, the T-Carb's 6 flute design with eccentric relief provides strength and supreme chip control at high speeds, and with surprising finish results.

The T-Carb was able to capacitate significantly higher speed and feed rates. Thus, the material removal rates for the T-Carb were almost double the MRR of the competitor’s tool. The total machining hours were almost cut in half, reducing the total machining cost by over $36,000. Download a PDF of the Case Study here to learn more.

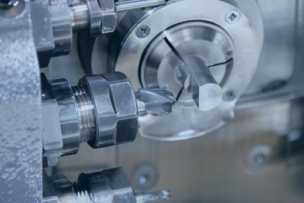

Watch the Series 51 T-Carb in action in the short video above (music and captions only, no transcript).

Previously Featured on KYOCERA's YouTube channel.

You can find the Series 51 T-Carb corner radius end mill or the square end mill on MSCDirect.com.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *