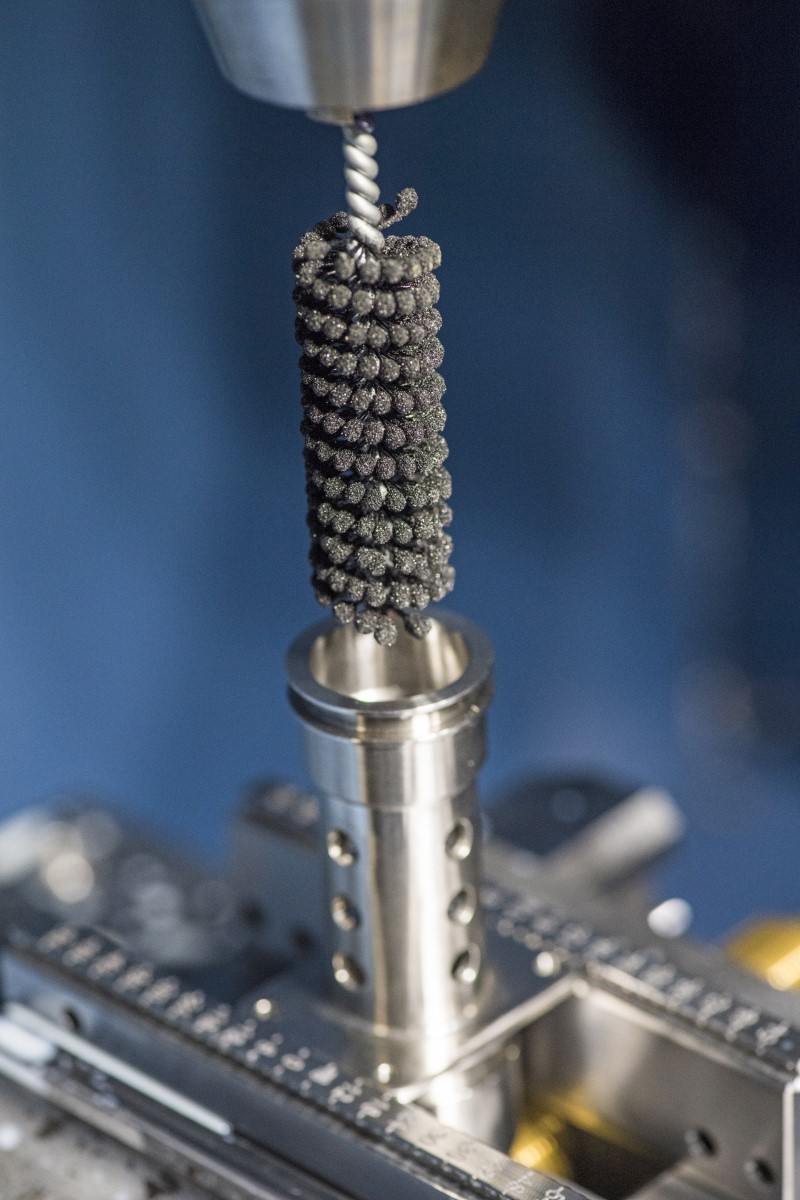

Flexible hone provides fine surface finish for internal bores, along with edge breaking of undercuts and deburring of intersecting drilled holes

For contract part manufacturers, the ability to produce tight tolerance parts at a faster rate is the key to remaining profitable in a crowded, highly competitive market. To do this, machine shops constantly seek out creative ways to improve on overall cycle time, including speeding metal finishing operations.

Although machine shops may have some auxiliary finishing equipment, the primary focus is on the machining. As a result, many shops must send parts out for secondary finishing steps such as thermal deburring, tumbling and burnishing.

However, for job shops like Wolfram Manufacturing, a company that machines metal parts with complex geometries on 4 and 5-axis machines, sending out parts for secondary finishing not only adds to the cost, but can impact quality and increase the time it takes to deliver the parts to customers.

“There’s the additional time, not to mention the additional cost of having someone else do the work time. In the competitive environment today, we’re often faced with short lead times from customers,” says Tim Urano, Quality Manager. “Having to send parts to an outside vendor eats into our lead time and takes significant planning.”

A better alternative for many machine shops, says Urano, is to incorporate machine tools that can complete the finishing tasks within the machining process.

“Any time we can incorporate secondary operations right into the machining process, we save time, money, and reduce our work in progress,” adds Urano.

In one example, Wolfram Manufacturing was charged with making a unique part for a sliding valve assembly with complex internal geometries that require a high surface finish on the internal bore and the elimination of any sharp edges from drilled holes.

Sliding valves, which are movable elements in a system, are used to direct the flow of a working fluid into the proper channel. The assembly is part of a larger product used in pressurized down-hole drilling tool.

Talk to Us!

This versatile abrasive tool for CNC machining reduces tool wearing during CNC machining. Not only does it decrease cycle times, but it also significantly improves finishing speed. The efficiency and precision it brings to the machining process are truly remarkable. Exciting advancements in CNC technology.

21Leave a reply

Your email address will not be published. Required fields are marked *