Material strength and surface finish testing examines the limits of crucial parts used in critical products. Here’s what you need to know about assessing the boundaries of material strength and construction, which are so important to the integrity of many products.

If you’ve ever asked for help when opening a jar of pickles, it’s likely that the bottling company never spoke to Mark Fridman. The same can be said for the bag of potato chips you tore open last week, only to see them fly all over the breakroom when the seam split right down the middle. Or the aspirin you needed whose bottle advertises a child-resistant cap that would more accurately be called human-resistant.

Fridman is the president of Mark-10 Corp. in Copiague, New York. He has a fun job. His company manufactures test equipment that attempts to rip, puncture, peel, crush and otherwise destroy various manufactured products. Many of them are consumer goods like those described above. But Fridman and the Mark-10 team are especially crucial to the automotive, aerospace and medical industries where product safety is paramount.

Forceful Determinations

It’s not all about destruction. Mark-10 equipment can measure seat belt release force, spring elasticity, the torque required to drive in a bone screw and countless other similar applications.

“The usability, reliability and durability of these and other manufactured objects can be quantified by a force or a torque value,” Fridman says. “So whether it's medical equipment or packaging materials or aerospace components, many of the things we use each day must be subjected to this kind of physical testing to make sure they meet the customer’s criteria for quality.”

Typically, testing occurs at the facility where these objects are manufactured, and often on the production line itself. Among the mechanical strength testing components that Mark-10 offers are:

Force gauges are used to capture tension and compression (pulling and pushing) forces in testing applications—the dumbbell-shaped test coupons with which many machine shops are familiar would be pulled apart on such a device.

Torque gauges measure clockwise or counterclockwise forces such as those applied to threaded fasteners, knobs and dials, or the pickle jar lid just mentioned.

Coefficient of friction (COF) gauges measure the static and kinetic forces generated when dragging a “sled” (a small metal pad) across a target material.

Wire pull testers are used to measure the pull-off force for crimped electrical terminals, tube terminations and wire-joining connectors.

Many of these are available in hand-held and benchtop versions, and are often used in conjunction with a manual or motorized test stand, various gripping fixtures and attachments, and the software to collate and analyze the test results.

“A lot of our customers, particularly when you’re talking about aerospace, automotive and medical products, must meet certain ISO, SAE or ASTM standards,” Fridman says. “There are also certain industry-specific standards, as well as those that manufacturers develop internally to assure their products will not fail in the field. A machine shop that offers assembly services, for example, might buy one of our units to check the spring tension on a lever or the force needed to close a door. The testing is very use-specific, and the applications almost too numerous to count.”

Read more: How Tool Balancing Boosts Tool Life and Productivity

Engineering Surfaces

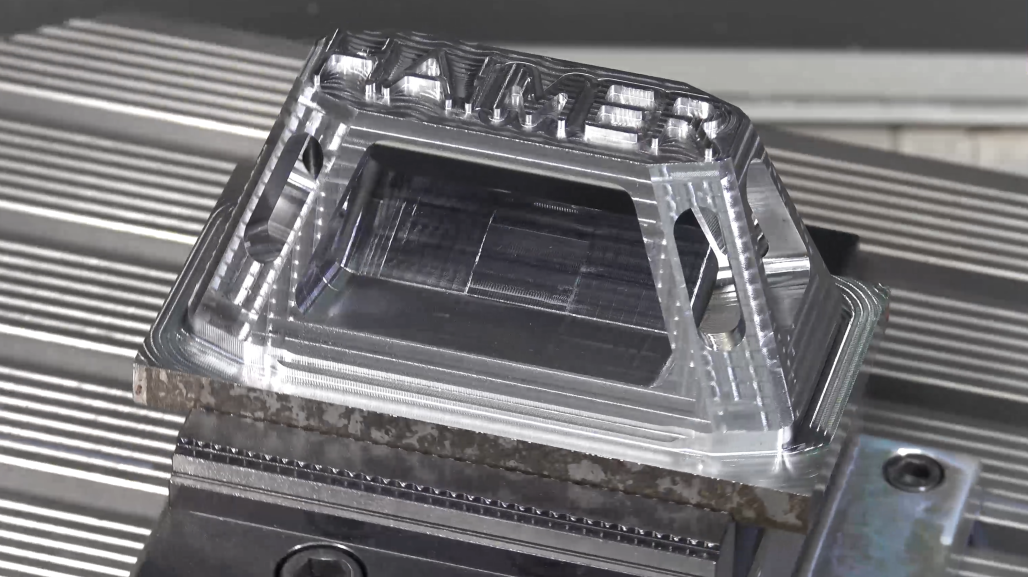

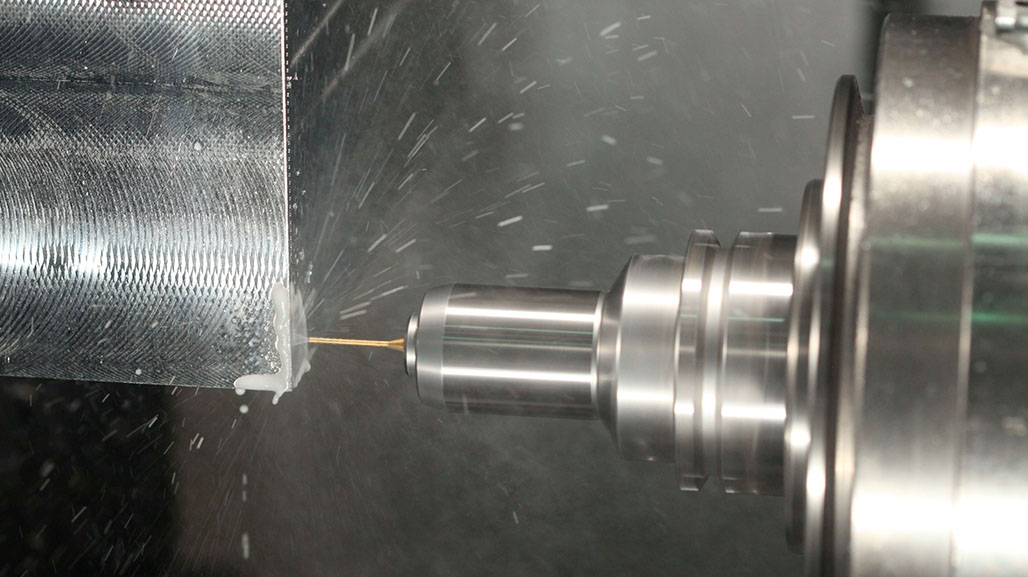

Pat Nugent is also interested in product quality, albeit in ways more well known to most machine shops. As the vice president of product management at Mahr Inc., based in Providence, Rhode Island, he is responsible for the company’s broad array of metrology equipment, including that used to measure surface roughness, roundness and form. He explains that the equipment used to quantify the first of these—roughness—was developed decades ago, at a time when machining was still being performed via cams and hand cranks. Further, those antique methods still influence the roughness standards used today.

“The first profilometers weren’t all that different from an old-fashioned record player, except that the needle moved up and down rather than side to side,” Nugent says. “These early analog devices used a mathematical calculation known as Rq, a type of root mean square averaging, to determine surface roughness. Today, most shops—at least those here in the U.S.—are more familiar with Ra, or average roughness.”

Nugent adds that in other parts of the world the Rz standard is typically used, which is the average peak to valley difference between five consecutive sampling lengths. He’s quick to point out, however, that a hundred or so surface measurement parameters and standards exist, and that manufacturers are often confused over which one to use and why.

“As the industry moved into the digital age and measuring equipment became more capable, people figured out how to collect various surface profiles and use them to quantify part quality,” he says. “Think about the bore on an engine cylinder. A manufacturer will typically rough machine the surface, then come back with a finish hone or grinding operation, which knocks off the peaks but leaves the valleys behind. If they can measure and therefore control these processes precisely enough, it creates a kind of engineered surface that provides optimal wear and lubrication characteristics.”

Read more: Managing Downtime: A Guide to Improving Shop Productivity During Manufacturing Slowdowns

Roughness and Waviness

The good news behind all this complexity is that modern measuring equipment like that provided by Mahr can easily switch between whatever surface roughness standards are on the drawing. They’re also able to measure waviness, which goes hand in hand with roughness.

Says Nugent: “I tell people to think about a wooden table that has had a heavy object resting on it. The bow in the middle can be thought of as waviness, while the grain you can feel with your fingernails is its surface roughness.”

It’s important to recognize that surface roughness and waviness are two-dimensional measurements. Take a series of such measurements using advanced optics like those found in a number of Mahr products and it’s possible to obtain detailed, three-dimensional views of a machined, cast, formed or printed object.

This goes back to what Nugent said earlier about engineered surfaces—the ability to measure and therefore control manufacturing processes at the microscopic level can lead to profound improvements in the finished object's behavior, presenting opportunities such as improved bone integration in orthopedic implants, and the creation of surfaces that more closely mimic those found in the organic world.

Read more: Medical Machining: Cutting Tool Manufacturers Offer Insights, Advice for Success

What obstacles have you faced when measuring a material’s strength? How did you overcome them? What tips can you share?

Measuring Hardness: It’s Not That Hard

One of the key indicators of any material’s machinability is its hardness.

As any machinist knows, soft metals such as aluminum and brass can be cut with ease, while machining superalloys and hardened tool steels calls for rigid equipment, relatively conservative cutting parameters, and in more extreme cases, may require grinding or electrical discharge machining.

As with surface roughness, measuring hardness can be confusing.

Manufacturers must understand conflicting standards, including Brinell, Vickers, Knoop, Mohs and Rockwell, the last of which has A, B and C scales to contend with. And for those who design manufactured products, an understanding of how hardness affects tensile strength and other metallurgical properties is a prerequisite to product performance and longevity.

Here again, the good news is that metrology companies have simplified the process.

Manufacturers such as Mitutoyo, Starrett and others offer a variety of hardness testing machines, and many of them are able to cover multiple scales in a single unit. Portable and benchtop units are available, as is analysis software, user training and loads of application advice.

Measuring hardness, it seems, isn’t all that hard.

Related Articles

Best Drill Bits for Stainless Steel: Advice from Those Who Know It Best

VIDEO: How to Drill Stainless Steel: 6 Tips

Clash of the Grinders: Behind the Science of Mill Scale and Rust Removal

The ROI of Filtration Systems: Investing In Long-Term Fluid Health