Brought To You by Jamie Goettler, Director of Customer Engagement at MSC Industrial Supply Co.

Additive manufacturing seems to monopolize the spotlight when it comes to part production these days. Manufacturers flock to industry trade shows to see how this novel technology has advanced and learn about how it might transform and benefit their operations.

There is good reason for the hype. Additive manufacturing may offer manufacturers a way to meet consumer demand for more customization. It also holds promise for product designers racing to be first to market with new designs. When it comes to rapid prototyping or one-off runs of unique products, additive technology is a valuable tool.

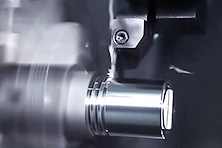

But the technology still has limitations and it isn’t the only innovator in industrial manufacturing. Traditional metalworking continues to be the real rock star.

Technology suppliers for traditional metalworking operations and applications continue to push the limits of what can be accomplished. Machine tool builders develop ever more sophisticated designs. Software advancements enhance machine control for faster cutting speeds, tighter tolerances and new ways of generating complex geometries.

At the same time, workholder, toolholder and cutting tool manufacturers are refining their technology and developing new solutions to increase productivity and profitability. Even raw part materials are changing to become stronger, lighter and more durable, which can add to the need for these manufacturers to develop new tools or products.

For the foreseeable future, the world will continue to revolve around products assembled with parts produced in high-volume machining operations.

Traditional metalworking enables manufacturers to produce more of those parts in less time. For tasks such as producing thousands of medical parts like bone screws or hydraulic fittings, additive manufacturing cannot match the economies of scale that traditional metalworking offers.

In addition, many parts are too large to be built with additive manufacturing methods. Others require materials currently unavailable for additive processes. For example, heavy load bearing materials, such as cast iron or steel for locomotive components, require conventional machining methods.

And additive manufacturing technologies often can’t produce final, finished pieces. Near-net shapes produced with additive technology nearly always need some finish machining. The time and materials costs invested in producing near-net shapes with additive technology makes finish machining precision even more critical, as scrap parts become more expensive.

Metalworking also provides several important economic advantages. Cost, as always, remains a dominant factor for many manufacturing executives deciding how to produce parts.

Manufacturers have invested heavily in the machines, tools and technology on their shop floors. While many are complementing their CNC operations with additive capabilities, they are not even close to replacing those huge investments in conventional CNC equipment.

Plus, other than single-part, customized or prototyping manufacturing scenarios, additive manufacturing tends to be cost prohibitive. Equipment is expensive and additive processes require higher cost raw materials and skilled labor to design parts and operate the machines.

U.S. manufacturers, meanwhile, have become more cost competitive. The cost of producing parts overseas has risen steadily over the last decade thanks to global wage growth and higher freight costs. U.S. companies now recognize the importance of calculating the total cost of offshoring rather than a cost per part estimate that can miss 20 to 30 percent of the full offshoring costs, according to the Reshoring Initiative.

Companies also must consider the risk of receiving poor quality products or products that differ from their specifications, as well as intellectual property theft, long shipping times, a lack of responsiveness and other problems. Many companies find it is faster, more reliable and more efficient to produce parts domestically.

The ability to maintain control over every aspect of the production process can be crucial in 21st century manufacturing. Medical manufacturers must be able to trace the full history of specific parts to meet regulatory and quality requirements. The government requires certain military parts to be manufactured domestically to enhance security. Companies with patents or proprietary technologies need to safeguard their intellectual property.

While people will always gravitate to new technologies, advancements in traditional metalworking can have a greater impact on a manufacturer’s current operations. Staying at the forefront of traditional metalworking offers enormous production benefits and high profitability.

The benefits extend beyond the company level, too, strengthening the U.S. economy. Successful manufacturers provide a huge benefit to the communities in which they operate, creating well-paying jobs and attracting suppliers and other nonmanufacturing businesses. In turn, this generates more demand for manufactured goods.

Additive manufacturing is certainly a compelling technology, but it is still just the opening act. Manufacturing is the headliner that sells the tickets and brings in the customers.

Previously featured on CTE magazine's website.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *