Tackling the Challenges of Machining Composite Materials

To machine FRPs without component damage, cutting edge quality and wear resistance are of absolute importance.

To machine FRPs without component damage, cutting edge quality and wear resistance are of absolute importance.

Fiber reinforced plastics (or FRPs) are used in applications where high specific strength and low weight are essential. To machine FRPs and stacks (FRP/metal-layer composite) without component damage, cutting edge quality and wear resistance are of absolute importance.

• Fraying or splitting of fibers

• Delamination

• Component damage through “peel-up” or “push-out”

• Burr development

• Thermal damage

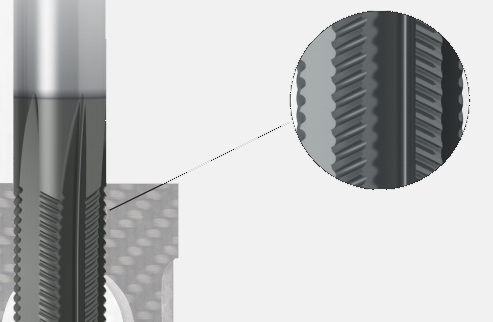

Guhring's FR 100 high-performance milling cutters address the challenges associated with machining FRPs.

The shearing action of the FR 100 prevents delamination, fiber fraying and thermal damage.

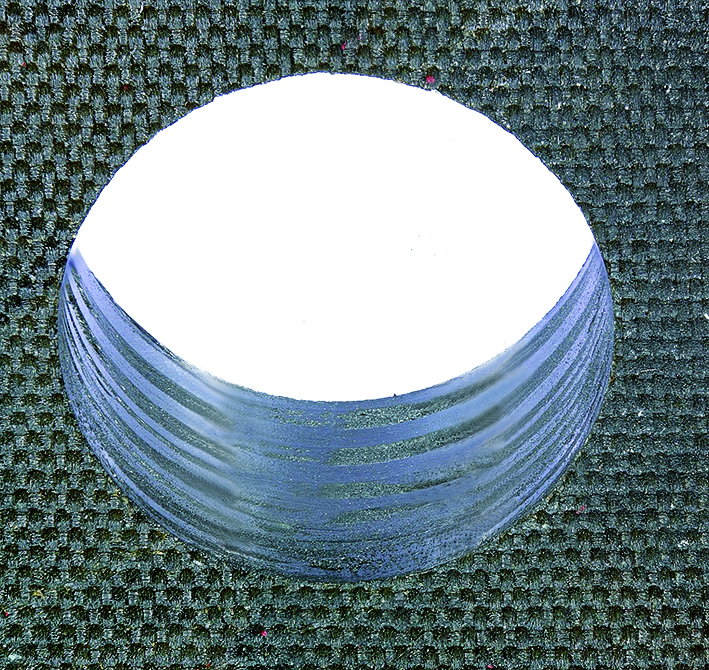

The goal is to avoid delamination or fraying of the FRP fibers. An exit hole with a clean edge proves Guhring’s success.

The exceptional hardness value of diamond enables this coating to tackle highly abrasive applications. Tool life is extended by the design features and the coating.

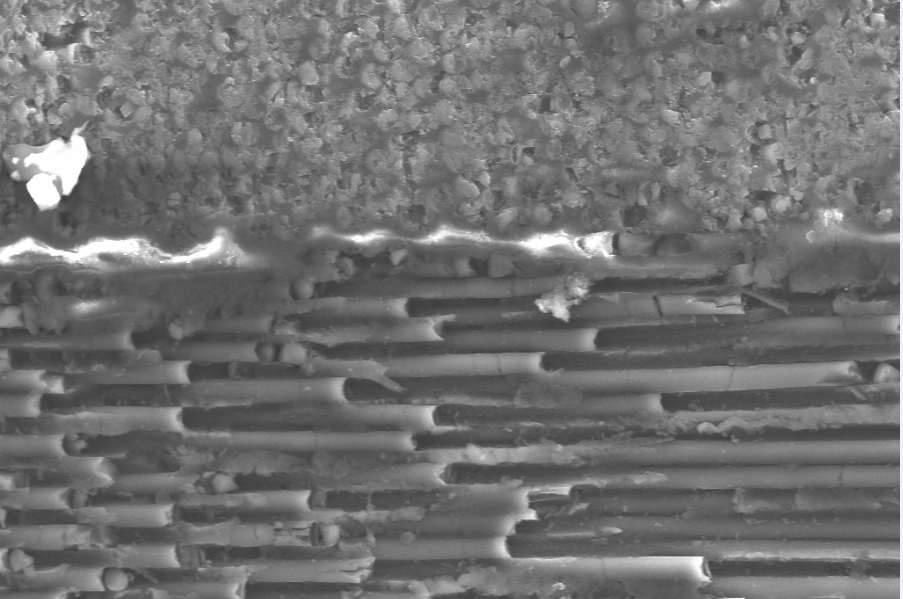

Machining results, magnified 500-fold, show the compression geometry paired with a superior cutting edge retains the structure and direction of the fibers in the material. No thermal damage or delamination occurs.

For more than 100 years, Guhring® has provided innovative solutions for round cutting tools. Guhring's extensive line of cutting tools are manufactured on machines and equipment designed and built by Guhring, ensuring the highest level of quality, accuracy and consistency. From micro drills and deep hole drills to cutting taps and finishing end mills, Guhring has the right solution for every job.